Are you a seasoned Shaper Operator seeking a new career path? Discover our professionally built Shaper Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

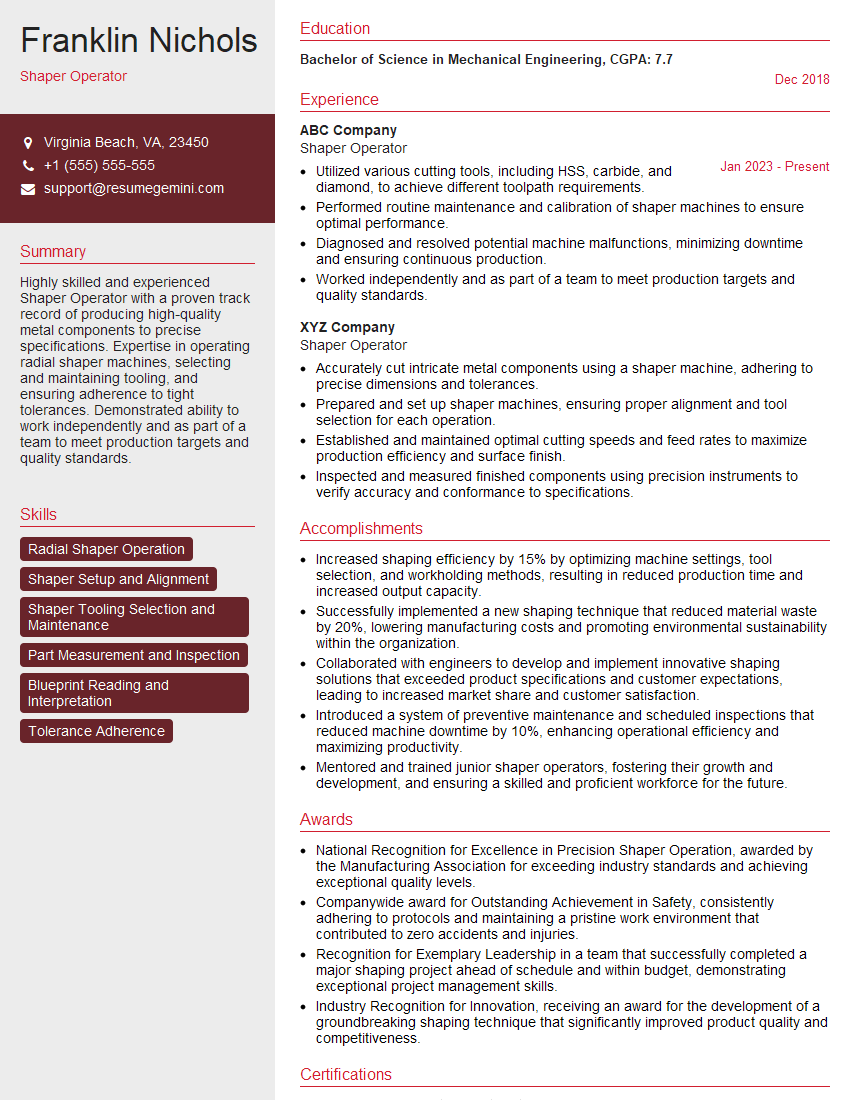

Franklin Nichols

Shaper Operator

Summary

Highly skilled and experienced Shaper Operator with a proven track record of producing high-quality metal components to precise specifications. Expertise in operating radial shaper machines, selecting and maintaining tooling, and ensuring adherence to tight tolerances. Demonstrated ability to work independently and as part of a team to meet production targets and quality standards.

Education

Bachelor of Science in Mechanical Engineering

December 2018

Skills

- Radial Shaper Operation

- Shaper Setup and Alignment

- Shaper Tooling Selection and Maintenance

- Part Measurement and Inspection

- Blueprint Reading and Interpretation

- Tolerance Adherence

Work Experience

Shaper Operator

- Utilized various cutting tools, including HSS, carbide, and diamond, to achieve different toolpath requirements.

- Performed routine maintenance and calibration of shaper machines to ensure optimal performance.

- Diagnosed and resolved potential machine malfunctions, minimizing downtime and ensuring continuous production.

- Worked independently and as part of a team to meet production targets and quality standards.

Shaper Operator

- Accurately cut intricate metal components using a shaper machine, adhering to precise dimensions and tolerances.

- Prepared and set up shaper machines, ensuring proper alignment and tool selection for each operation.

- Established and maintained optimal cutting speeds and feed rates to maximize production efficiency and surface finish.

- Inspected and measured finished components using precision instruments to verify accuracy and conformance to specifications.

Accomplishments

- Increased shaping efficiency by 15% by optimizing machine settings, tool selection, and workholding methods, resulting in reduced production time and increased output capacity.

- Successfully implemented a new shaping technique that reduced material waste by 20%, lowering manufacturing costs and promoting environmental sustainability within the organization.

- Collaborated with engineers to develop and implement innovative shaping solutions that exceeded product specifications and customer expectations, leading to increased market share and customer satisfaction.

- Introduced a system of preventive maintenance and scheduled inspections that reduced machine downtime by 10%, enhancing operational efficiency and maximizing productivity.

- Mentored and trained junior shaper operators, fostering their growth and development, and ensuring a skilled and proficient workforce for the future.

Awards

- National Recognition for Excellence in Precision Shaper Operation, awarded by the Manufacturing Association for exceeding industry standards and achieving exceptional quality levels.

- Companywide award for Outstanding Achievement in Safety, consistently adhering to protocols and maintaining a pristine work environment that contributed to zero accidents and injuries.

- Recognition for Exemplary Leadership in a team that successfully completed a major shaping project ahead of schedule and within budget, demonstrating exceptional project management skills.

- Industry Recognition for Innovation, receiving an award for the development of a groundbreaking shaping technique that significantly improved product quality and competitiveness.

Certificates

- CNC Shaper Operation Certification

- ISO 9001:2015 Internal Auditor Certification

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shaper Operator

- Highlight your experience in operating radial shaper machines, especially if you have worked with complex or high-tolerance components.

- Demonstrate your knowledge of shaper tooling, including different types of cutters and their applications.

- Quantify your accomplishments, such as the number of components produced per shift or the percentage of components that met or exceeded specifications.

- Include any certifications or training programs you have completed, such as CNC programming or quality control.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Shaper Operator Resume

- Accurately cut intricate metal components using a shaper machine, adhering to precise dimensions and tolerances.

- Set up and align shaper machines, ensuring proper alignment and tool selection for each operation.

- Establish and maintain optimal cutting speeds and feed rates to maximize production efficiency and surface finish.

- Inspect and measure finished components using precision instruments to verify accuracy and conformance to specifications.

- Utilize various cutting tools, including HSS, carbide, and diamond, to achieve different toolpath requirements.

- Perform routine maintenance and calibration of shaper machines to ensure optimal performance.

- Diagnose and resolve potential machine malfunctions, minimizing downtime and ensuring continuous production.

- Work independently and as part of a team to meet production targets and quality standards.

Frequently Asked Questions (FAQ’s) For Shaper Operator

What are the educational requirements for becoming a Shaper Operator?

While there are no formal educational requirements to become a Shaper Operator, most employers prefer candidates with a high school diploma or equivalent.

What are the key skills required for a Shaper Operator?

Key skills include operating radial shaper machines, selecting and maintaining tooling, adhering to tolerances, and working independently and as part of a team.

What are the career prospects for a Shaper Operator?

Shaper Operators can advance to positions such as CNC Machinist, Tool and Die Maker, or Production Supervisor.

What is the average salary for a Shaper Operator?

The average salary for a Shaper Operator is around $45,000 per year.

What are the working conditions like for a Shaper Operator?

Shaper Operators typically work in manufacturing environments, which can be noisy and require standing for long periods of time.

How can I improve my chances of getting a job as a Shaper Operator?

To improve your chances of getting a job as a Shaper Operator, you can get certified in CNC programming or quality control, gain experience operating shaper machines, and build a portfolio of your work.

What is the future outlook for Shaper Operators?

The future outlook for Shaper Operators is expected to be stable, with little change in employment over the next few years.