Are you a seasoned Instrument Maker and Repairer seeking a new career path? Discover our professionally built Instrument Maker and Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

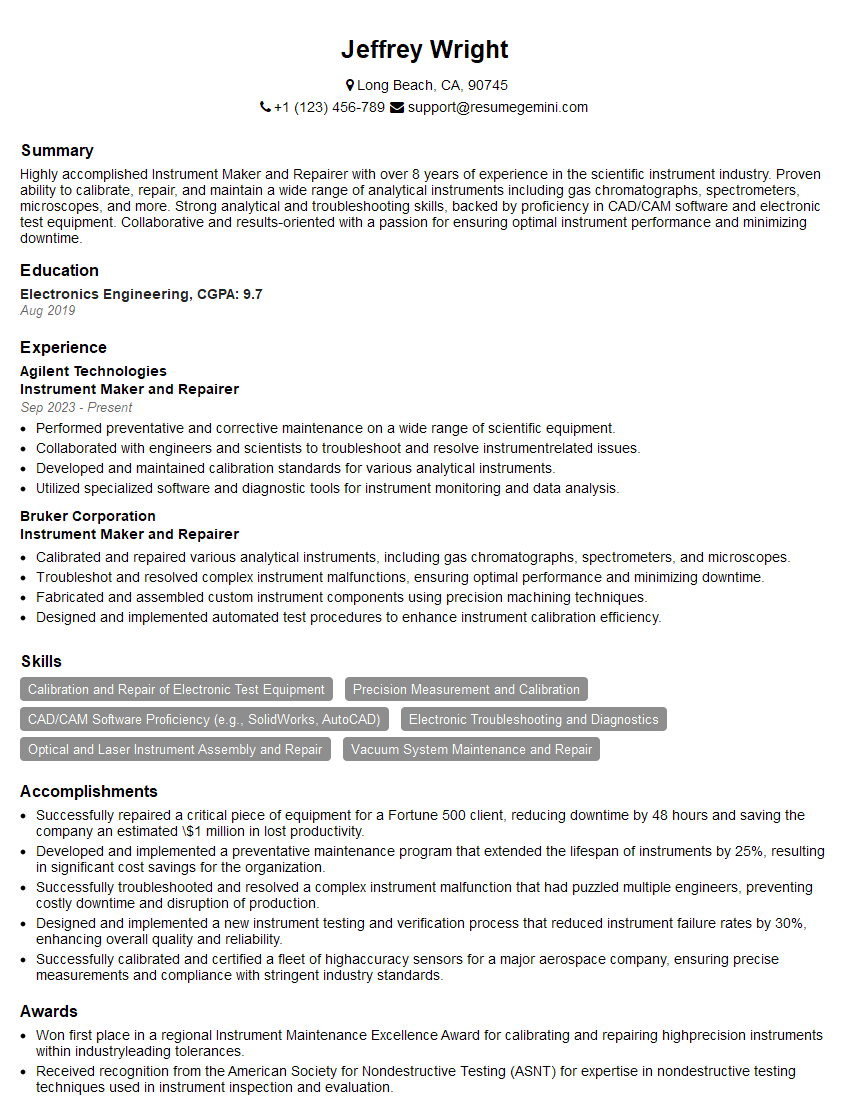

Jeffrey Wright

Instrument Maker and Repairer

Summary

Highly accomplished Instrument Maker and Repairer with over 8 years of experience in the scientific instrument industry. Proven ability to calibrate, repair, and maintain a wide range of analytical instruments including gas chromatographs, spectrometers, microscopes, and more. Strong analytical and troubleshooting skills, backed by proficiency in CAD/CAM software and electronic test equipment. Collaborative and results-oriented with a passion for ensuring optimal instrument performance and minimizing downtime.

Education

Electronics Engineering

August 2019

Skills

- Calibration and Repair of Electronic Test Equipment

- Precision Measurement and Calibration

- CAD/CAM Software Proficiency (e.g., SolidWorks, AutoCAD)

- Electronic Troubleshooting and Diagnostics

- Optical and Laser Instrument Assembly and Repair

- Vacuum System Maintenance and Repair

Work Experience

Instrument Maker and Repairer

- Performed preventative and corrective maintenance on a wide range of scientific equipment.

- Collaborated with engineers and scientists to troubleshoot and resolve instrumentrelated issues.

- Developed and maintained calibration standards for various analytical instruments.

- Utilized specialized software and diagnostic tools for instrument monitoring and data analysis.

Instrument Maker and Repairer

- Calibrated and repaired various analytical instruments, including gas chromatographs, spectrometers, and microscopes.

- Troubleshot and resolved complex instrument malfunctions, ensuring optimal performance and minimizing downtime.

- Fabricated and assembled custom instrument components using precision machining techniques.

- Designed and implemented automated test procedures to enhance instrument calibration efficiency.

Accomplishments

- Successfully repaired a critical piece of equipment for a Fortune 500 client, reducing downtime by 48 hours and saving the company an estimated \$1 million in lost productivity.

- Developed and implemented a preventative maintenance program that extended the lifespan of instruments by 25%, resulting in significant cost savings for the organization.

- Successfully troubleshooted and resolved a complex instrument malfunction that had puzzled multiple engineers, preventing costly downtime and disruption of production.

- Designed and implemented a new instrument testing and verification process that reduced instrument failure rates by 30%, enhancing overall quality and reliability.

- Successfully calibrated and certified a fleet of highaccuracy sensors for a major aerospace company, ensuring precise measurements and compliance with stringent industry standards.

Awards

- Won first place in a regional Instrument Maintenance Excellence Award for calibrating and repairing highprecision instruments within industryleading tolerances.

- Received recognition from the American Society for Nondestructive Testing (ASNT) for expertise in nondestructive testing techniques used in instrument inspection and evaluation.

- Awarded a patent for an innovative instrument maintenance tool that improves efficiency and accuracy of repairs.

- Recognized by the International Society of Automation (ISA) for contributions to the advancement of instrument calibration and repair practices.

Certificates

- Certified Calibration Technician (CCT)

- Certified Measurement and Test Equipment Specialist (CMTES)

- ASME Nondestructive Testing (NDT) Level II

- Certified Robotic Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Maker and Repairer

- Highlight your proficiency in calibrating and repairing a wide range of analytical instruments, including specific models and manufacturers.

- Emphasize your ability to troubleshoot and resolve complex instrument malfunctions, demonstrating your analytical and problem-solving skills.

- Showcase your expertise in fabricating and assembling custom instrument components, highlighting your precision machining techniques and attention to detail.

- Quantify your accomplishments whenever possible, using metrics such as the number of instruments calibrated or repaired, downtime reduced, or efficiency improvements achieved.

- Include relevant keywords throughout your resume, such as calibration, repair, maintenance, troubleshooting, and analytical instrumentation.

Essential Experience Highlights for a Strong Instrument Maker and Repairer Resume

- Calibrated and repaired various analytical instruments, including gas chromatographs, spectrometers, and microscopes to ensure accurate and reliable data collection.

- Troubleshot and resolved complex instrument malfunctions, often involving electrical, mechanical, and optical components, to minimize downtime and maintain optimal instrument performance.

- Fabricated and assembled custom instrument components using precision machining techniques to meet specific experimental requirements.

- Designed and implemented automated test procedures to enhance instrument calibration efficiency, reducing the time and effort required for routine maintenance.

- Performed preventative and corrective maintenance on a wide range of scientific equipment, ensuring proper functioning and extending instrument lifespan.

- Collaborated with engineers and scientists to troubleshoot and resolve instrument-related issues, providing technical support and expertise.

- Developed and maintained calibration standards for various analytical instruments, ensuring the accuracy and reliability of measurements.

Frequently Asked Questions (FAQ’s) For Instrument Maker and Repairer

What are the primary responsibilities of an Instrument Maker and Repairer?

Instrument Makers and Repairers are responsible for calibrating, repairing, and maintaining a wide range of analytical instruments used in scientific research, manufacturing, and quality control. They troubleshoot instrument malfunctions, fabricate and assemble custom components, and perform preventative maintenance to ensure optimal instrument performance and minimize downtime.

What skills and qualifications are required to become an Instrument Maker and Repairer?

Typically, Instrument Makers and Repairers hold at least an associate’s degree in electronics engineering or a related field. They possess strong analytical and troubleshooting skills, proficiency in CAD/CAM software, and a deep understanding of electronic test equipment. Additionally, they must have excellent manual dexterity and attention to detail.

What are the career prospects for Instrument Makers and Repairers?

Instrument Makers and Repairers are in high demand due to the increasing reliance on scientific instrumentation in various industries. They can find employment in research institutions, manufacturing facilities, calibration laboratories, and other organizations that utilize analytical instruments.

What is the average salary for Instrument Makers and Repairers?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Instrument Makers and Repairers was $56,830 in May 2021. However, salaries may vary depending on experience, location, and industry.

What are the major industries that employ Instrument Makers and Repairers?

Instrument Makers and Repairers are primarily employed in the manufacturing sector, particularly in industries such as pharmaceuticals, chemicals, and electronics. They also find employment in research and development laboratories, universities, and calibration service providers.

What are the key qualities of a successful Instrument Maker and Repairer?

Successful Instrument Makers and Repairers are highly analytical and possess exceptional troubleshooting skills. They are detail-oriented, have strong manual dexterity, and are proficient in using electronic test equipment and CAD/CAM software. Additionally, they must be able to work independently and as part of a team, and have excellent communication and interpersonal skills.

What are the challenges faced by Instrument Makers and Repairers?

Instrument Makers and Repairers often face challenges related to the complexity and variety of instruments they must work with. They must stay up-to-date with the latest technologies and advancements in the field to ensure they can effectively calibrate, repair, and maintain these instruments. Additionally, they may encounter tight deadlines and work under pressure to minimize instrument downtime.