Are you a seasoned Laboratory Machinist seeking a new career path? Discover our professionally built Laboratory Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

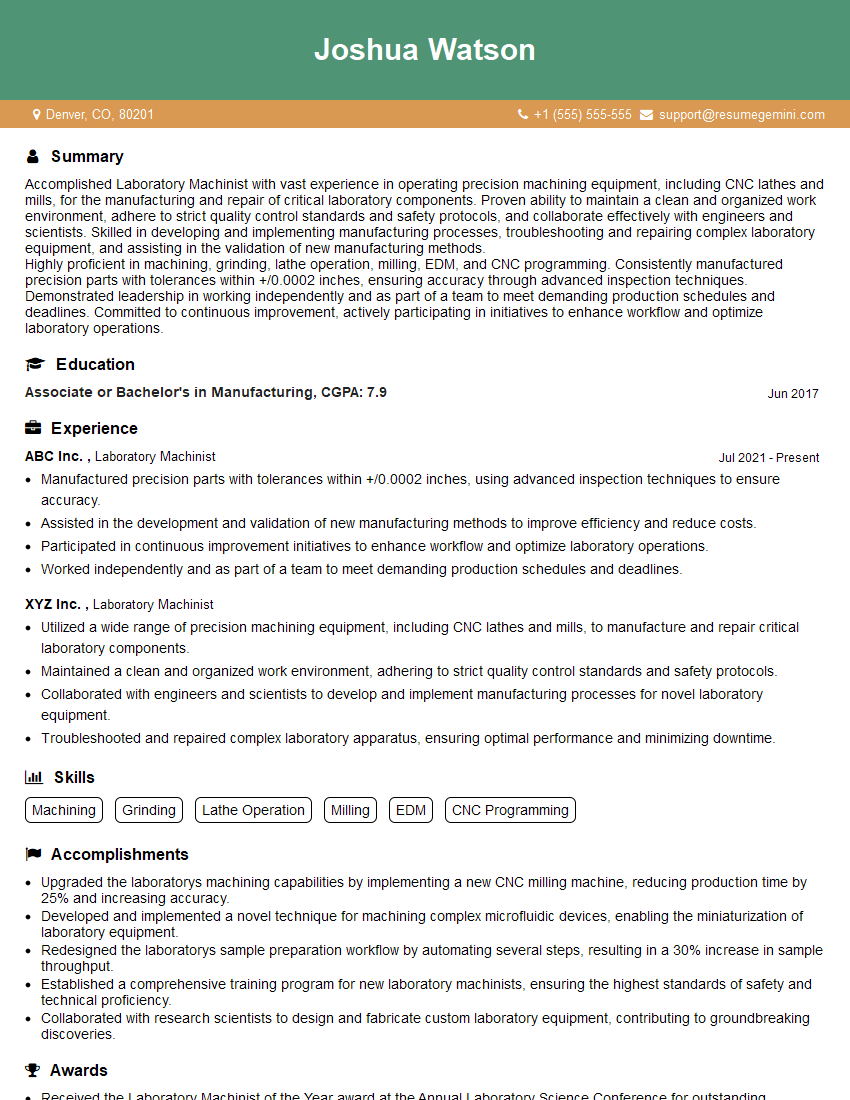

Joshua Watson

Laboratory Machinist

Summary

Accomplished Laboratory Machinist with vast experience in operating precision machining equipment, including CNC lathes and mills, for the manufacturing and repair of critical laboratory components. Proven ability to maintain a clean and organized work environment, adhere to strict quality control standards and safety protocols, and collaborate effectively with engineers and scientists. Skilled in developing and implementing manufacturing processes, troubleshooting and repairing complex laboratory equipment, and assisting in the validation of new manufacturing methods.

Highly proficient in machining, grinding, lathe operation, milling, EDM, and CNC programming. Consistently manufactured precision parts with tolerances within +/0.0002 inches, ensuring accuracy through advanced inspection techniques. Demonstrated leadership in working independently and as part of a team to meet demanding production schedules and deadlines. Committed to continuous improvement, actively participating in initiatives to enhance workflow and optimize laboratory operations.

Education

Associate or Bachelor’s in Manufacturing

June 2017

Skills

- Machining

- Grinding

- Lathe Operation

- Milling

- EDM

- CNC Programming

Work Experience

Laboratory Machinist

- Manufactured precision parts with tolerances within +/0.0002 inches, using advanced inspection techniques to ensure accuracy.

- Assisted in the development and validation of new manufacturing methods to improve efficiency and reduce costs.

- Participated in continuous improvement initiatives to enhance workflow and optimize laboratory operations.

- Worked independently and as part of a team to meet demanding production schedules and deadlines.

Laboratory Machinist

- Utilized a wide range of precision machining equipment, including CNC lathes and mills, to manufacture and repair critical laboratory components.

- Maintained a clean and organized work environment, adhering to strict quality control standards and safety protocols.

- Collaborated with engineers and scientists to develop and implement manufacturing processes for novel laboratory equipment.

- Troubleshooted and repaired complex laboratory apparatus, ensuring optimal performance and minimizing downtime.

Accomplishments

- Upgraded the laboratorys machining capabilities by implementing a new CNC milling machine, reducing production time by 25% and increasing accuracy.

- Developed and implemented a novel technique for machining complex microfluidic devices, enabling the miniaturization of laboratory equipment.

- Redesigned the laboratorys sample preparation workflow by automating several steps, resulting in a 30% increase in sample throughput.

- Established a comprehensive training program for new laboratory machinists, ensuring the highest standards of safety and technical proficiency.

- Collaborated with research scientists to design and fabricate custom laboratory equipment, contributing to groundbreaking discoveries.

Awards

- Received the Laboratory Machinist of the Year award at the Annual Laboratory Science Conference for outstanding contributions to the field.

- Recognized with the Excellence in Precision Machining award for consistently exceeding quality standards and achieving exceptional precision in all laboratory components.

- Honored by the Laboratory Association with the Innovation in Laboratory Machining award for groundbreaking work in developing automated machining processes.

- Recipient of the Laboratory Safety Excellence Award for maintaining an impeccable safety record and implementing innovative safety protocols.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- ISO 9001:2015

- ASME B46.1

- ANSI/NCSL Z540-1

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Laboratory Machinist

- Highlight your proficiency in precision machining techniques and your ability to meet tight tolerances.

- Showcase your experience in operating and programming CNC equipment, including lathes and mills.

- Emphasize your understanding of laboratory equipment and your ability to troubleshoot and repair complex apparatus.

- Demonstrate your commitment to quality control and your ability to work in a clean and organized environment.

- Provide specific examples of your contributions to manufacturing process improvement and cost reduction initiatives.

Essential Experience Highlights for a Strong Laboratory Machinist Resume

- Utilized precision machining equipment, including CNC lathes and mills, to manufacture and repair laboratory components.

- Maintained a clean and organized work environment, adhering to strict quality control standards and safety protocols.

- Collaborated with engineers and scientists to develop and implement manufacturing processes for laboratory equipment.

- Troubleshooted and repaired complex laboratory apparatus, ensuring optimal performance and minimizing downtime.

- Manufactured precision parts with tolerances within +/0.0002 inches, using advanced inspection techniques to ensure accuracy.

- Assisted in the development and validation of new manufacturing methods to improve efficiency and reduce costs.

- Participated in continuous improvement initiatives to enhance workflow and optimize laboratory operations.

- Worked independently and as part of a team to meet demanding production schedules and deadlines.

- Assumed additional responsibilities as needed to support the team and laboratory operations.

Frequently Asked Questions (FAQ’s) For Laboratory Machinist

What is the primary role of a Laboratory Machinist?

A Laboratory Machinist is responsible for operating precision machining equipment to manufacture, repair, and maintain critical laboratory components and apparatus, ensuring optimal performance and adherence to quality control standards.

What are the key skills required for a Laboratory Machinist?

Laboratory Machinists require proficiency in machining techniques, including lathe operation, milling, grinding, EDM, and CNC programming. They must possess a strong understanding of laboratory equipment and be able to troubleshoot and repair complex apparatus. Additionally, they must adhere to strict quality control standards and safety protocols.

What are the career prospects for a Laboratory Machinist?

Laboratory Machinists can advance their careers by specializing in particular areas of laboratory equipment or by pursuing management roles. They may also become involved in research and development, working with engineers and scientists to design and develop new laboratory equipment and processes.

What is the job outlook for Laboratory Machinists?

The job outlook for Laboratory Machinists is expected to be favorable as there is a growing demand for skilled technicians in the manufacturing and laboratory sectors. With the increasing use of precision machining equipment and the need for reliable and efficient laboratory apparatus, Laboratory Machinists will continue to be in high demand.

What are the educational requirements for a Laboratory Machinist?

Laboratory Machinists typically need an Associate’s or Bachelor’s degree in Manufacturing or a related field. They may also complete apprenticeship programs or receive on-the-job training.

What are the typical working conditions for a Laboratory Machinist?

Laboratory Machinists typically work in clean and well-lit workshops or laboratories. They may work independently or as part of a team, and they often need to wear protective gear, such as safety glasses and earplugs.