Are you a seasoned Machinist Tool and Die seeking a new career path? Discover our professionally built Machinist Tool and Die Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

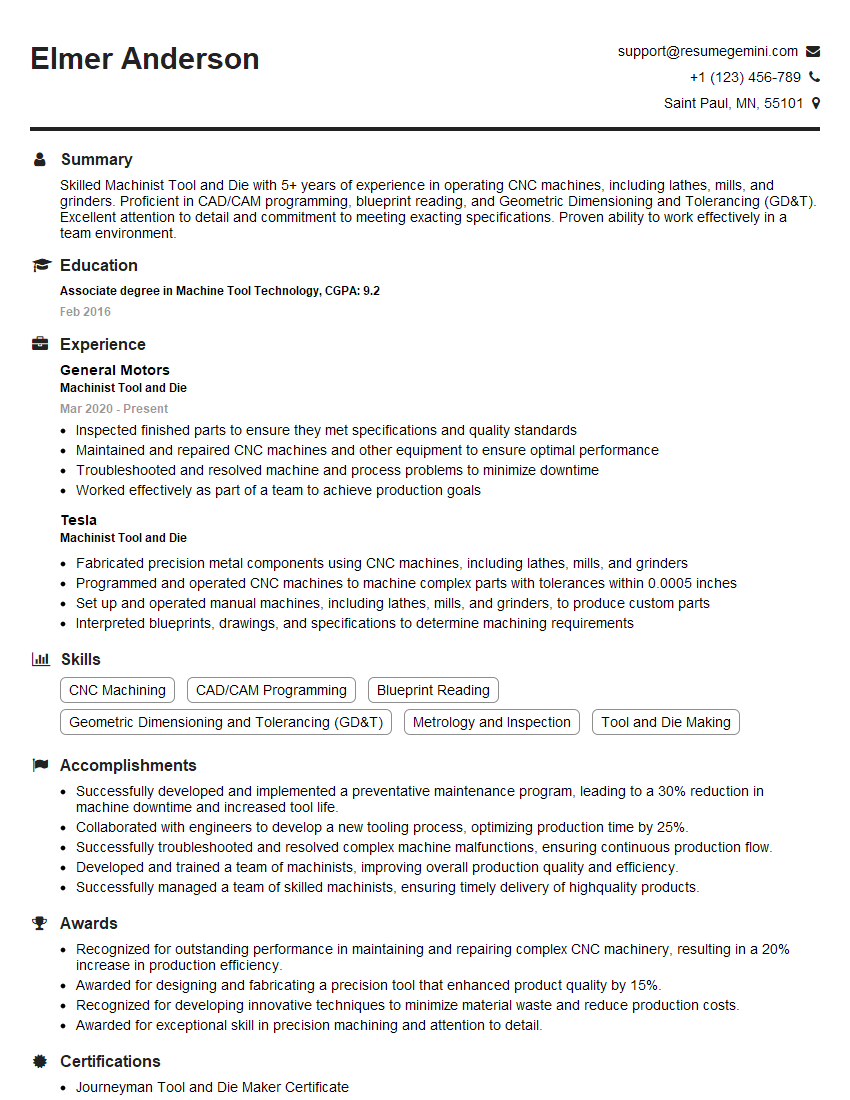

Elmer Anderson

Machinist Tool and Die

Summary

Skilled Machinist Tool and Die with 5+ years of experience in operating CNC machines, including lathes, mills, and grinders. Proficient in CAD/CAM programming, blueprint reading, and Geometric Dimensioning and Tolerancing (GD&T). Excellent attention to detail and commitment to meeting exacting specifications. Proven ability to work effectively in a team environment.

Education

Associate degree in Machine Tool Technology

February 2016

Skills

- CNC Machining

- CAD/CAM Programming

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Metrology and Inspection

- Tool and Die Making

Work Experience

Machinist Tool and Die

- Inspected finished parts to ensure they met specifications and quality standards

- Maintained and repaired CNC machines and other equipment to ensure optimal performance

- Troubleshooted and resolved machine and process problems to minimize downtime

- Worked effectively as part of a team to achieve production goals

Machinist Tool and Die

- Fabricated precision metal components using CNC machines, including lathes, mills, and grinders

- Programmed and operated CNC machines to machine complex parts with tolerances within 0.0005 inches

- Set up and operated manual machines, including lathes, mills, and grinders, to produce custom parts

- Interpreted blueprints, drawings, and specifications to determine machining requirements

Accomplishments

- Successfully developed and implemented a preventative maintenance program, leading to a 30% reduction in machine downtime and increased tool life.

- Collaborated with engineers to develop a new tooling process, optimizing production time by 25%.

- Successfully troubleshooted and resolved complex machine malfunctions, ensuring continuous production flow.

- Developed and trained a team of machinists, improving overall production quality and efficiency.

- Successfully managed a team of skilled machinists, ensuring timely delivery of highquality products.

Awards

- Recognized for outstanding performance in maintaining and repairing complex CNC machinery, resulting in a 20% increase in production efficiency.

- Awarded for designing and fabricating a precision tool that enhanced product quality by 15%.

- Recognized for developing innovative techniques to minimize material waste and reduce production costs.

- Awarded for exceptional skill in precision machining and attention to detail.

Certificates

- Journeyman Tool and Die Maker Certificate

- CNC Programming Certificate

- Lean Manufacturing Certification

- Geometric Dimensioning and Tolerancing (GD&T) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machinist Tool and Die

- Highlight your experience and skills in operating CNC machines.

- Showcase your knowledge of CAD/CAM programming and blueprint reading.

- Emphasize your attention to detail and commitment to meeting exacting specifications.

- Include examples of projects or accomplishments that demonstrate your skills and abilities.

Essential Experience Highlights for a Strong Machinist Tool and Die Resume

- Fabricated precision metal components using CNC machines.

- Programmed and operated CNC machines to machine complex parts with tolerances within 0.0005 inches.

- Set up and operated manual machines, including lathes, mills, and grinders, to produce custom parts.

- Interpreted blueprints, drawings, and specifications to determine machining requirements.

- Inspected finished parts to ensure they met specifications and quality standards.

- Maintained and repaired CNC machines and other equipment to ensure optimal performance.

Frequently Asked Questions (FAQ’s) For Machinist Tool and Die

What are the primary responsibilities of a Machinist Tool and Die?

Machinist Tool and Die are responsible for fabricating precision metal components using CNC machines, programming and operating CNC machines, setting up and operating manual machines, interpreting blueprints, inspecting finished parts, and maintaining and repairing equipment.

What qualifications are required to become a Machinist Tool and Die?

Most employers require a high school diploma or equivalent and some post-secondary education in machine tool technology or a related field.

What are the career prospects for Machinist Tool and Die?

Machinist Tool and Die are in high demand due to the increasing use of CNC machines in manufacturing. The job outlook is expected to be excellent over the next few years.

What is the average salary for a Machinist Tool and Die?

The average salary for a Machinist Tool and Die is around $45,000 per year.