Are you a seasoned Manual Machinist seeking a new career path? Discover our professionally built Manual Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

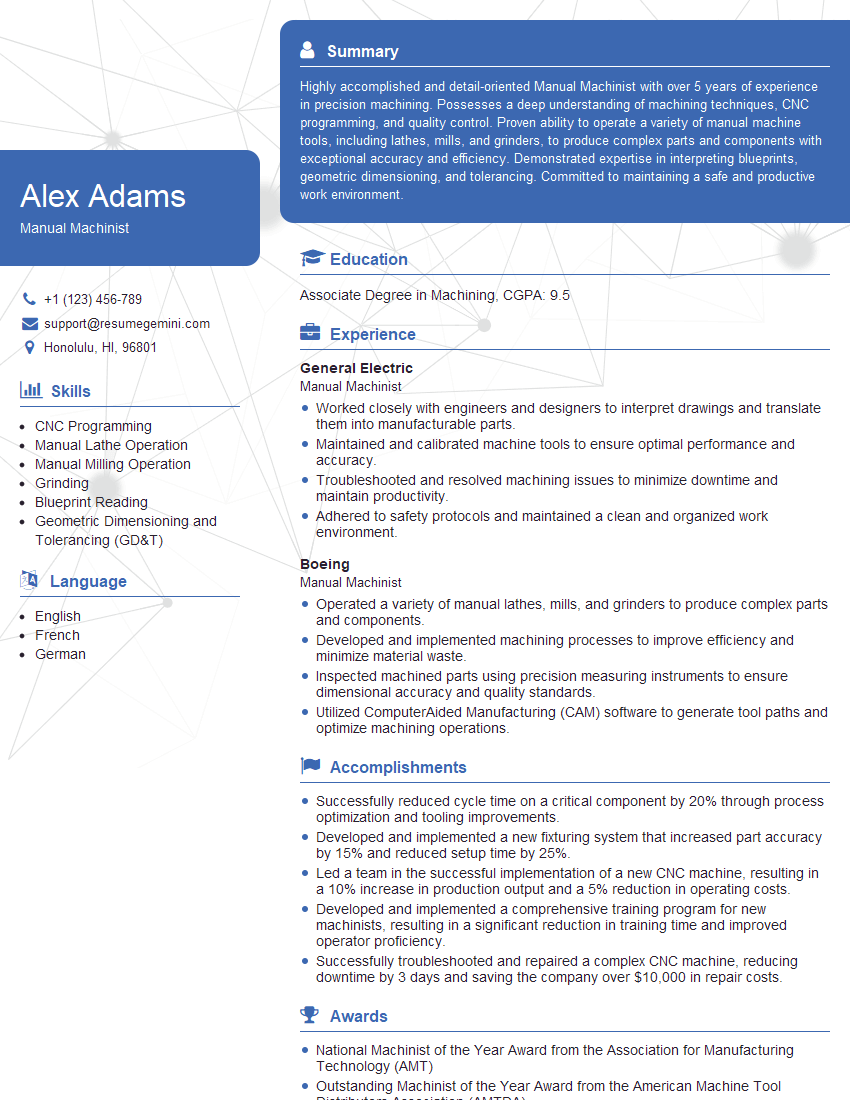

Alex Adams

Manual Machinist

Summary

Highly accomplished and detail-oriented Manual Machinist with over 5 years of experience in precision machining. Possesses a deep understanding of machining techniques, CNC programming, and quality control. Proven ability to operate a variety of manual machine tools, including lathes, mills, and grinders, to produce complex parts and components with exceptional accuracy and efficiency. Demonstrated expertise in interpreting blueprints, geometric dimensioning, and tolerancing. Committed to maintaining a safe and productive work environment.

Education

Associate Degree in Machining

December 2014

Skills

- CNC Programming

- Manual Lathe Operation

- Manual Milling Operation

- Grinding

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Manual Machinist

- Worked closely with engineers and designers to interpret drawings and translate them into manufacturable parts.

- Maintained and calibrated machine tools to ensure optimal performance and accuracy.

- Troubleshooted and resolved machining issues to minimize downtime and maintain productivity.

- Adhered to safety protocols and maintained a clean and organized work environment.

Manual Machinist

- Operated a variety of manual lathes, mills, and grinders to produce complex parts and components.

- Developed and implemented machining processes to improve efficiency and minimize material waste.

- Inspected machined parts using precision measuring instruments to ensure dimensional accuracy and quality standards.

- Utilized ComputerAided Manufacturing (CAM) software to generate tool paths and optimize machining operations.

Accomplishments

- Successfully reduced cycle time on a critical component by 20% through process optimization and tooling improvements.

- Developed and implemented a new fixturing system that increased part accuracy by 15% and reduced setup time by 25%.

- Led a team in the successful implementation of a new CNC machine, resulting in a 10% increase in production output and a 5% reduction in operating costs.

- Developed and implemented a comprehensive training program for new machinists, resulting in a significant reduction in training time and improved operator proficiency.

- Successfully troubleshooted and repaired a complex CNC machine, reducing downtime by 3 days and saving the company over $10,000 in repair costs.

Awards

- National Machinist of the Year Award from the Association for Manufacturing Technology (AMT)

- Outstanding Machinist of the Year Award from the American Machine Tool Distributors Association (AMTDA)

- Excellence in Precision Machining Award from the Precision Machining Technology Association (PMTA)

- Distinguished Machinist Award from the Society of Manufacturing Engineers (SME)

Certificates

- National Institute for Metalworking Skills (NIMS)

- Precision Machining Institute (PMI)

- American Society for Quality (ASQ)

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manual Machinist

- Highlight your experience and skills in operating manual machine tools, including lathes, mills, and grinders.

- Emphasize your knowledge of CNC programming, geometric dimensioning, and tolerancing.

- Provide specific examples of projects where you have successfully produced complex parts and components.

- Quantify your accomplishments whenever possible, such as reducing cycle times or improving production efficiency.

- Demonstrate your commitment to safety and compliance with industry standards.

Essential Experience Highlights for a Strong Manual Machinist Resume

- Operated a variety of manual machine tools, including lathes, mills, and grinders, to produce complex parts and components.

- Developed and implemented machining processes to improve efficiency and minimize material waste.

- Inspected machined parts using precision measuring instruments to ensure dimensional accuracy and quality standards.

- Utilized Computer-Aided Manufacturing (CAM) software to generate tool paths and optimize machining operations.

- Worked closely with engineers and designers to interpret drawings and translate them into manufacturable parts.

- Maintained and calibrated machine tools to ensure optimal performance and accuracy.

- Troubleshooted and resolved machining issues to minimize downtime and maintain productivity.

Frequently Asked Questions (FAQ’s) For Manual Machinist

What are the primary responsibilities of a Manual Machinist?

Manual Machinists are responsible for operating manual machine tools, such as lathes, mills, and grinders, to produce complex parts and components. They also develop and implement machining processes, inspect machined parts, and work closely with engineers and designers to interpret drawings and translate them into manufacturable parts.

What skills are required to be a successful Manual Machinist?

Successful Manual Machinists typically have a combination of technical skills, including experience operating manual machine tools, knowledge of CNC programming, and an understanding of geometric dimensioning and tolerancing. They also possess strong attention to detail, problem-solving abilities, and a commitment to safety.

What are the career prospects for Manual Machinists?

Manual Machinists are in high demand in a variety of industries, including manufacturing, aerospace, and automotive. With experience and training, they can advance to supervisory roles or specialize in specific areas of machining, such as mold making or precision grinding.

What is the average salary for a Manual Machinist?

The average salary for a Manual Machinist in the United States is around \$45,000 per year. However, salaries can vary depending on experience, location, and industry.

Are there any certifications or licenses required to become a Manual Machinist?

While not typically required, obtaining certifications or licenses can enhance your credibility and demonstrate your commitment to the profession. Relevant certifications include the Certified Journeyman Machinist (CJM) from the National Institute for Metalworking Skills (NIMS) and the Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME).

What is the job outlook for Manual Machinists?

The job outlook for Manual Machinists is expected to be favorable in the coming years. As industries continue to rely on precision-machined parts and components, the demand for skilled machinists is likely to remain strong.

What are the benefits of working as a Manual Machinist?

Working as a Manual Machinist offers several benefits, including job stability, competitive salaries, and opportunities for advancement. Machinists play a crucial role in the manufacturing process and are in high demand across various industries.

What are the challenges of working as a Manual Machinist?

Working as a Manual Machinist can be physically demanding and requires attention to detail and precision. Machinists often work with heavy machinery and must adhere to strict safety protocols to prevent accidents.