Are you a seasoned Tool and Die Machinist seeking a new career path? Discover our professionally built Tool and Die Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

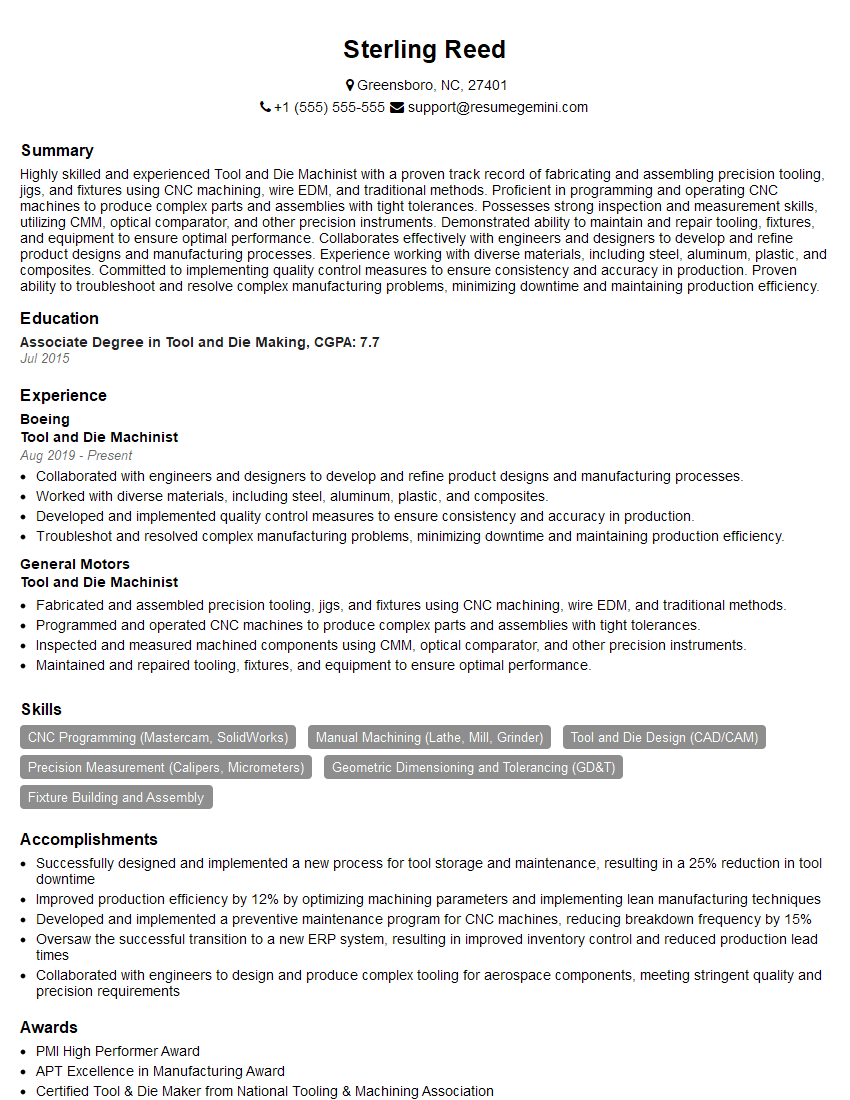

Sterling Reed

Tool and Die Machinist

Summary

Highly skilled and experienced Tool and Die Machinist with a proven track record of fabricating and assembling precision tooling, jigs, and fixtures using CNC machining, wire EDM, and traditional methods. Proficient in programming and operating CNC machines to produce complex parts and assemblies with tight tolerances. Possesses strong inspection and measurement skills, utilizing CMM, optical comparator, and other precision instruments. Demonstrated ability to maintain and repair tooling, fixtures, and equipment to ensure optimal performance. Collaborates effectively with engineers and designers to develop and refine product designs and manufacturing processes. Experience working with diverse materials, including steel, aluminum, plastic, and composites. Committed to implementing quality control measures to ensure consistency and accuracy in production. Proven ability to troubleshoot and resolve complex manufacturing problems, minimizing downtime and maintaining production efficiency.

Education

Associate Degree in Tool and Die Making

July 2015

Skills

- CNC Programming (Mastercam, SolidWorks)

- Manual Machining (Lathe, Mill, Grinder)

- Tool and Die Design (CAD/CAM)

- Precision Measurement (Calipers, Micrometers)

- Geometric Dimensioning and Tolerancing (GD&T)

- Fixture Building and Assembly

Work Experience

Tool and Die Machinist

- Collaborated with engineers and designers to develop and refine product designs and manufacturing processes.

- Worked with diverse materials, including steel, aluminum, plastic, and composites.

- Developed and implemented quality control measures to ensure consistency and accuracy in production.

- Troubleshot and resolved complex manufacturing problems, minimizing downtime and maintaining production efficiency.

Tool and Die Machinist

- Fabricated and assembled precision tooling, jigs, and fixtures using CNC machining, wire EDM, and traditional methods.

- Programmed and operated CNC machines to produce complex parts and assemblies with tight tolerances.

- Inspected and measured machined components using CMM, optical comparator, and other precision instruments.

- Maintained and repaired tooling, fixtures, and equipment to ensure optimal performance.

Accomplishments

- Successfully designed and implemented a new process for tool storage and maintenance, resulting in a 25% reduction in tool downtime

- Improved production efficiency by 12% by optimizing machining parameters and implementing lean manufacturing techniques

- Developed and implemented a preventive maintenance program for CNC machines, reducing breakdown frequency by 15%

- Oversaw the successful transition to a new ERP system, resulting in improved inventory control and reduced production lead times

- Collaborated with engineers to design and produce complex tooling for aerospace components, meeting stringent quality and precision requirements

Awards

- PMI High Performer Award

- APT Excellence in Manufacturing Award

- Certified Tool & Die Maker from National Tooling & Machining Association

- ISO 90012015 Certified Lead Auditor

Certificates

- Journeyman Tool and Die Maker

- Master Toolmaker

- Certified Mold Maker

- Certified GD&T Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Machinist

- Highlight your experience and skills in using CNC machining, wire EDM, and traditional methods to fabricate and assemble precision tooling, jigs, and fixtures.

- Showcase your proficiency in programming and operating CNC machines to produce complex parts and assemblies with tight tolerances.

- Emphasize your inspection and measurement skills, including the use of CMM, optical comparator, and other precision instruments.

- Describe your experience in maintaining and repairing tooling, fixtures, and equipment to ensure optimal performance.

- Highlight your ability to collaborate with engineers and designers to develop and refine product designs and manufacturing processes.

Essential Experience Highlights for a Strong Tool and Die Machinist Resume

- Fabricate and assemble precision tooling, jigs, and fixtures using CNC machining, wire EDM, and traditional methods.

- Program and operate CNC machines to produce complex parts and assemblies with tight tolerances.

- Inspect and measure machined components using CMM, optical comparator, and other precision instruments.

- Maintain and repair tooling, fixtures, and equipment to ensure optimal performance.

- Collaborate with engineers and designers to develop and refine product designs and manufacturing processes.

- Work with diverse materials, including steel, aluminum, plastic, and composites.

- Develop and implement quality control measures to ensure consistency and accuracy in production.

Frequently Asked Questions (FAQ’s) For Tool and Die Machinist

What is the role of a Tool and Die Machinist?

A Tool and Die Machinist is responsible for fabricating and assembling precision tooling, jigs, and fixtures used in the manufacturing process. They use a variety of CNC machining, wire EDM, and traditional methods to create complex parts and assemblies with tight tolerances.

What skills are required to be a successful Tool and Die Machinist?

Successful Tool and Die Machinists typically have strong skills in CNC programming and operation, inspection and measurement, and maintenance and repair. They are also proficient in working with diverse materials, including steel, aluminum, plastic, and composites.

What is the job outlook for Tool and Die Machinists?

The job outlook for Tool and Die Machinists is expected to be positive over the next few years. There is a growing demand for skilled machinists in various industries, including aerospace, automotive, and medical.

What is the average salary for a Tool and Die Machinist?

The average salary for a Tool and Die Machinist varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers was \$50,590 in May 2021.

What are the career advancement opportunities for Tool and Die Machinists?

Tool and Die Machinists can advance their careers by becoming supervisors, managers, or engineers. They may also specialize in a particular area of machining, such as CNC programming or mold making.

What is the best way to prepare for a career as a Tool and Die Machinist?

The best way to prepare for a career as a Tool and Die Machinist is to complete a formal training program. Many community colleges and vocational schools offer programs in tool and die making. These programs typically include coursework in CNC programming, operation, and maintenance, as well as inspection and measurement.

What are some of the challenges faced by Tool and Die Machinists?

Some of the challenges faced by Tool and Die Machinists include working with tight tolerances, meeting deadlines, and working with hazardous materials. They must also be able to troubleshoot and resolve complex manufacturing problems.

What are some of the benefits of being a Tool and Die Machinist?

Some of the benefits of being a Tool and Die Machinist include a competitive salary, job security, and the opportunity to work with cutting-edge technology. They also have the satisfaction of knowing that they are playing a vital role in the manufacturing process.