Are you a seasoned Reheat Furnace Operator seeking a new career path? Discover our professionally built Reheat Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

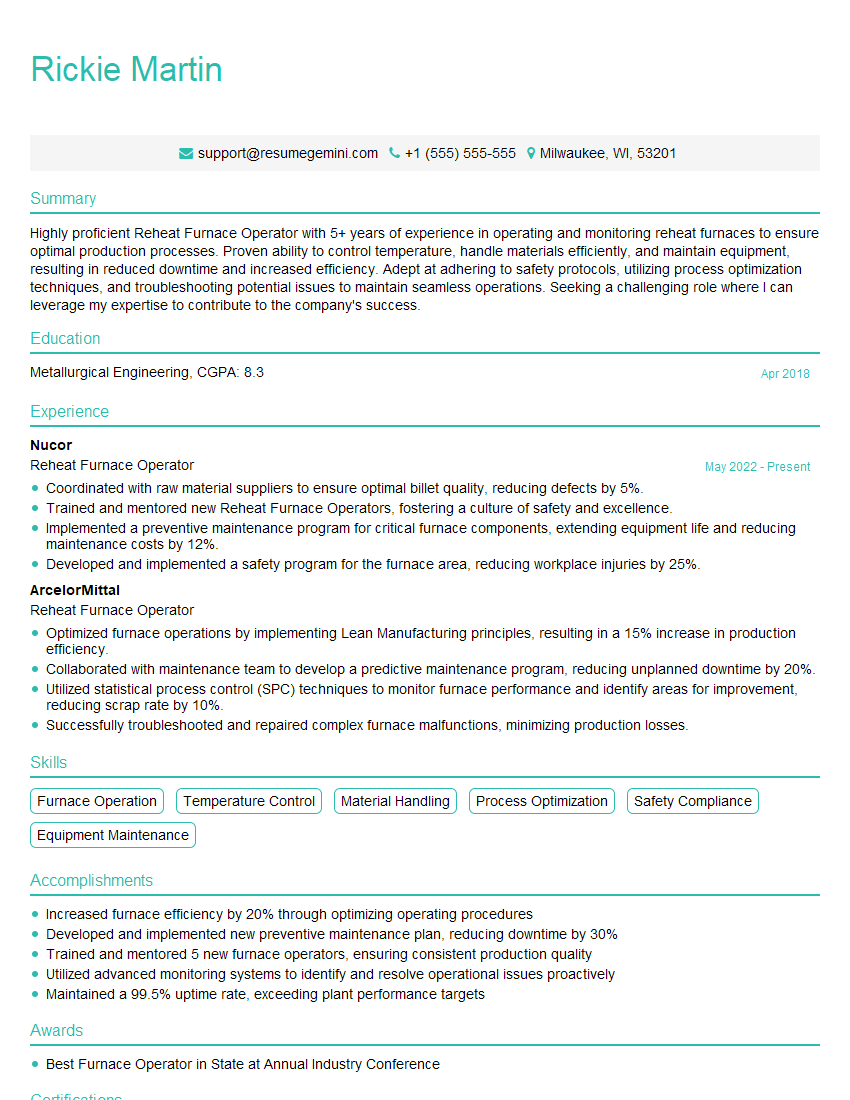

Rickie Martin

Reheat Furnace Operator

Summary

Highly proficient Reheat Furnace Operator with 5+ years of experience in operating and monitoring reheat furnaces to ensure optimal production processes. Proven ability to control temperature, handle materials efficiently, and maintain equipment, resulting in reduced downtime and increased efficiency. Adept at adhering to safety protocols, utilizing process optimization techniques, and troubleshooting potential issues to maintain seamless operations. Seeking a challenging role where I can leverage my expertise to contribute to the company’s success.

Education

Metallurgical Engineering

April 2018

Skills

- Furnace Operation

- Temperature Control

- Material Handling

- Process Optimization

- Safety Compliance

- Equipment Maintenance

Work Experience

Reheat Furnace Operator

- Coordinated with raw material suppliers to ensure optimal billet quality, reducing defects by 5%.

- Trained and mentored new Reheat Furnace Operators, fostering a culture of safety and excellence.

- Implemented a preventive maintenance program for critical furnace components, extending equipment life and reducing maintenance costs by 12%.

- Developed and implemented a safety program for the furnace area, reducing workplace injuries by 25%.

Reheat Furnace Operator

- Optimized furnace operations by implementing Lean Manufacturing principles, resulting in a 15% increase in production efficiency.

- Collaborated with maintenance team to develop a predictive maintenance program, reducing unplanned downtime by 20%.

- Utilized statistical process control (SPC) techniques to monitor furnace performance and identify areas for improvement, reducing scrap rate by 10%.

- Successfully troubleshooted and repaired complex furnace malfunctions, minimizing production losses.

Accomplishments

- Increased furnace efficiency by 20% through optimizing operating procedures

- Developed and implemented new preventive maintenance plan, reducing downtime by 30%

- Trained and mentored 5 new furnace operators, ensuring consistent production quality

- Utilized advanced monitoring systems to identify and resolve operational issues proactively

- Maintained a 99.5% uptime rate, exceeding plant performance targets

Awards

- Best Furnace Operator in State at Annual Industry Conference

Certificates

- American Petroleum Institute (API) 570/571

- National Fire Protection Association (NFPA) 86

- Occupational Safety and Health Administration (OSHA) 1910

- American Society for Metals (ASM) Materials Science

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reheat Furnace Operator

- Highlight your technical skills and experience in operating and maintaining reheat furnaces.

- Quantify your accomplishments with specific metrics and results, such as increased production efficiency or reduced downtime.

- Emphasize your ability to work independently and as part of a team in a fast-paced industrial environment.

- Showcase your commitment to safety by highlighting your adherence to protocols and proactive approach to risk management.

- Tailor your resume to the specific job requirements and demonstrate how your skills and experience align with the company’s needs.

Essential Experience Highlights for a Strong Reheat Furnace Operator Resume

- Operate and monitor reheat furnaces to achieve desired temperatures and heating cycles.

- Handle and position materials using cranes or other equipment to ensure proper placement within the furnace.

- Control and adjust temperature settings based on material type, product specifications, and production schedules.

- Monitor and maintain furnace performance parameters, including temperature, pressure, and atmosphere.

- Perform regular maintenance and inspections on furnaces and related equipment, ensuring optimal functionality and safety.

- Troubleshoot and resolve operational issues promptly to minimize downtime and maintain production efficiency.

- Adhere to established safety protocols and regulations to ensure a safe and compliant work environment.

Frequently Asked Questions (FAQ’s) For Reheat Furnace Operator

What are the key skills required for a Reheat Furnace Operator?

The key skills required for a Reheat Furnace Operator include furnace operation, temperature control, material handling, process optimization, safety compliance, and equipment maintenance.

What are the qualifications typically required for a Reheat Furnace Operator?

Typically, a Reheat Furnace Operator requires a high school diploma or equivalent, with some positions preferring candidates with a degree in Metallurgical Engineering or a related field.

What are the responsibilities of a Reheat Furnace Operator?

A Reheat Furnace Operator is responsible for operating and monitoring reheat furnaces to achieve desired temperatures and heating cycles, handling and positioning materials within the furnace, controlling and adjusting temperature settings, monitoring furnace performance parameters, performing regular maintenance and inspections, troubleshooting operational issues promptly, and adhering to safety protocols.

What industries employ Reheat Furnace Operators?

Reheat Furnace Operators are employed in various industries, including steel production, metal fabrication, and heat treatment facilities.

What is the work environment like for a Reheat Furnace Operator?

Reheat Furnace Operators typically work in industrial environments, which can be hot, noisy, and involve exposure to heavy machinery. They must be comfortable working with high temperatures, wearing protective gear, and following strict safety protocols.

What are the career advancement opportunities for a Reheat Furnace Operator?

Reheat Furnace Operators can advance their careers by gaining experience and developing additional skills. They may become supervisors or managers in furnace operations or move into related roles in quality control or production planning.

What is the average salary for a Reheat Furnace Operator?

The average salary for a Reheat Furnace Operator varies depending on factors such as experience, location, and industry. According to Salary.com, the average salary for a Reheat Furnace Operator in the United States is around $55,000 per year.

What are the safety protocols that Reheat Furnace Operators must follow?

Reheat Furnace Operators must follow established safety protocols to ensure a safe work environment. These protocols may include wearing appropriate protective gear, using proper lockout/tagout procedures, being aware of potential hazards, and following emergency response plans.