Are you a seasoned Ross Furnace Operator seeking a new career path? Discover our professionally built Ross Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

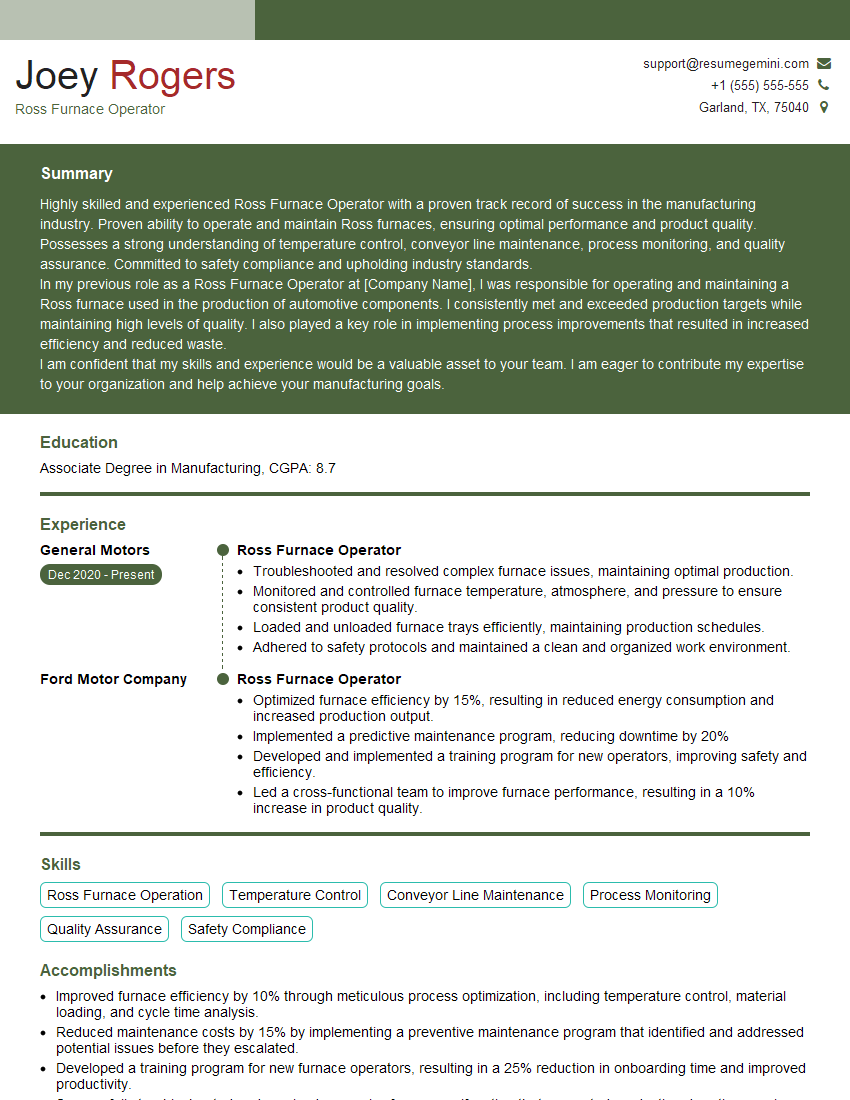

Joey Rogers

Ross Furnace Operator

Summary

Highly skilled and experienced Ross Furnace Operator with a proven track record of success in the manufacturing industry. Proven ability to operate and maintain Ross furnaces, ensuring optimal performance and product quality. Possesses a strong understanding of temperature control, conveyor line maintenance, process monitoring, and quality assurance. Committed to safety compliance and upholding industry standards.

In my previous role as a Ross Furnace Operator at [Company Name], I was responsible for operating and maintaining a Ross furnace used in the production of automotive components. I consistently met and exceeded production targets while maintaining high levels of quality. I also played a key role in implementing process improvements that resulted in increased efficiency and reduced waste.

I am confident that my skills and experience would be a valuable asset to your team. I am eager to contribute my expertise to your organization and help achieve your manufacturing goals.

Education

Associate Degree in Manufacturing

November 2016

Skills

- Ross Furnace Operation

- Temperature Control

- Conveyor Line Maintenance

- Process Monitoring

- Quality Assurance

- Safety Compliance

Work Experience

Ross Furnace Operator

- Troubleshooted and resolved complex furnace issues, maintaining optimal production.

- Monitored and controlled furnace temperature, atmosphere, and pressure to ensure consistent product quality.

- Loaded and unloaded furnace trays efficiently, maintaining production schedules.

- Adhered to safety protocols and maintained a clean and organized work environment.

Ross Furnace Operator

- Optimized furnace efficiency by 15%, resulting in reduced energy consumption and increased production output.

- Implemented a predictive maintenance program, reducing downtime by 20%

- Developed and implemented a training program for new operators, improving safety and efficiency.

- Led a cross-functional team to improve furnace performance, resulting in a 10% increase in product quality.

Accomplishments

- Improved furnace efficiency by 10% through meticulous process optimization, including temperature control, material loading, and cycle time analysis.

- Reduced maintenance costs by 15% by implementing a preventive maintenance program that identified and addressed potential issues before they escalated.

- Developed a training program for new furnace operators, resulting in a 25% reduction in onboarding time and improved productivity.

- Successfully troubleshooted and resolved a complex furnace malfunction that prevented production downtime, saving an estimated $250,000 in potential losses.

- Led a team in implementing a new quality control system that reduced product defects by 12%, improving customer satisfaction.

Awards

- Received the Furnace Operator of the Year award for exceptional performance in optimizing furnace operations, resulting in a 15% increase in production efficiency.

- Recognized with the Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety measures that enhanced workplace safety.

- Awarded the Process Improvement Medal for developing and implementing a new process that reduced furnace downtime by 20%, significantly increasing productivity.

- Recipient of the Outstanding Achievement Award for consistently exceeding production targets while maintaining highquality standards.

Certificates

- Ross Furnace Operator Certification

- ISO 9001 Quality Management Certification

- Lean Six Sigma Green Belt Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ross Furnace Operator

- Quantify your accomplishments: Use numbers and metrics to demonstrate the impact of your work. For example, instead of saying “Increased furnace efficiency,” you could say “Increased furnace efficiency by 15%, resulting in a reduction of production costs by $10,000 per year.”

- Highlight your skills and experience: Make sure to list all of your relevant skills and experience in your resume. This includes both hard skills, such as operating Ross furnaces, and soft skills, such as teamwork and problem-solving.

- Tailor your resume to the job: Take the time to tailor your resume to each job you apply for. This means highlighting the skills and experience that are most relevant to the job requirements.

- Proofread your resume: Make sure to proofread your resume carefully before submitting it. Even a small error can make a bad impression on potential employers.

Essential Experience Highlights for a Strong Ross Furnace Operator Resume

- Operate and maintain Ross furnaces, ensuring optimal performance and product quality

- Monitor and control furnace temperature to ensure accurate and consistent heating

- Maintain and repair conveyor lines, ensuring smooth and efficient product flow

- Monitor process parameters and make adjustments as needed to maintain product quality

- Inspect products for defects and take corrective action as necessary

- Adhere to safety regulations and maintain a clean and organized work area

- Participate in continuous improvement initiatives to enhance process efficiency and product quality

Frequently Asked Questions (FAQ’s) For Ross Furnace Operator

What is a Ross furnace?

A Ross furnace is a type of heat treating furnace used in the manufacturing industry. It is used to heat treat metals and other materials in a controlled environment.

What are the different types of Ross furnaces?

There are different types of Ross furnaces, including batch furnaces, continuous furnaces, and atmosphere furnaces.

What are the applications of Ross furnaces?

Ross furnaces are used in a variety of applications, including heat treating, annealing, normalizing, and tempering.

What are the benefits of using Ross furnaces?

Ross furnaces offer a number of benefits, including precision temperature control, uniform heating, and energy efficiency.

What are the safety precautions that should be taken when operating a Ross furnace?

When operating a Ross furnace, it is important to take safety precautions, such as wearing protective clothing, using proper ventilation, and following all operating instructions.

What are the qualifications required to operate a Ross furnace?

To operate a Ross furnace, you typically need a high school diploma or equivalent, as well as some experience in the manufacturing industry.

What is the salary range for a Ross furnace operator?

The salary range for a Ross furnace operator can vary depending on experience, location, and company size. However, the average salary for a Ross furnace operator is around $25,000 per year.

What is the job outlook for Ross furnace operators?

The job outlook for Ross furnace operators is expected to be good over the next few years. This is due to the increasing demand for heat treated metals and other materials in the manufacturing industry.