Are you a seasoned Die Cast Operator (DCO) seeking a new career path? Discover our professionally built Die Cast Operator (DCO) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

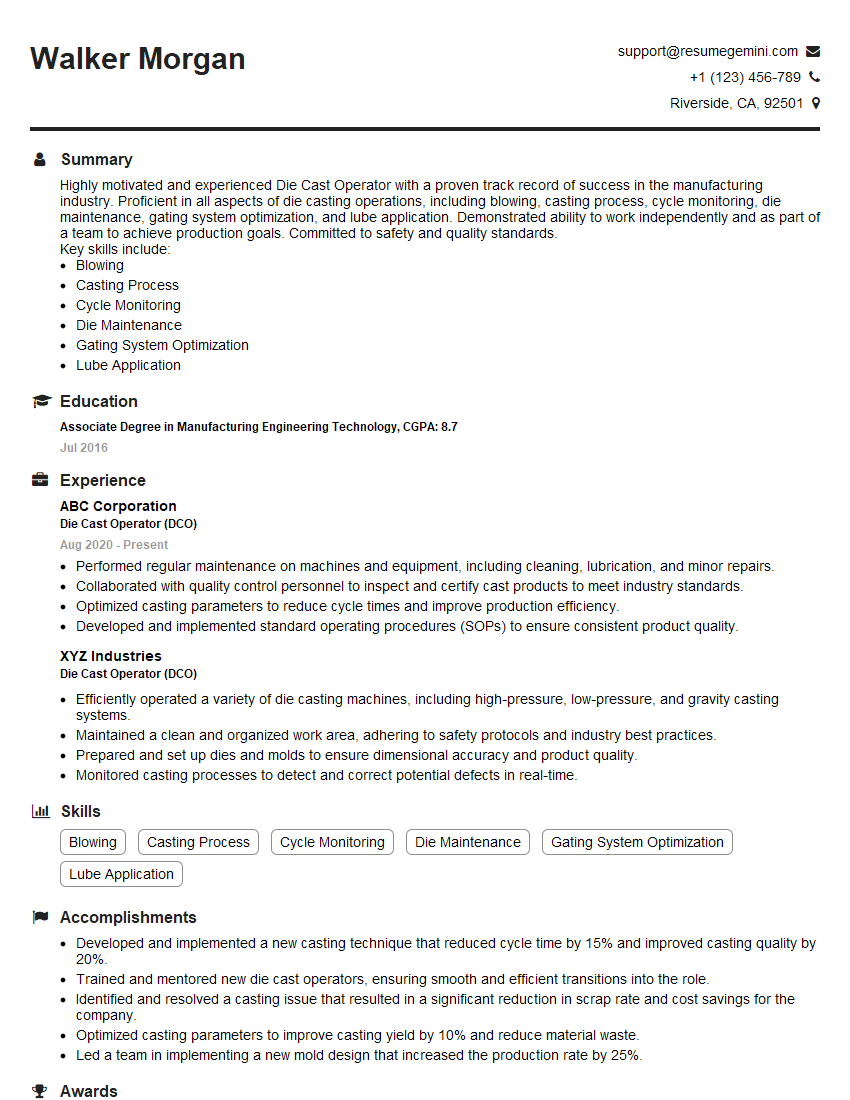

Walker Morgan

Die Cast Operator (DCO)

Summary

Highly motivated and experienced Die Cast Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of die casting operations, including blowing, casting process, cycle monitoring, die maintenance, gating system optimization, and lube application. Demonstrated ability to work independently and as part of a team to achieve production goals. Committed to safety and quality standards.

Key skills include:

- Blowing

- Casting Process

- Cycle Monitoring

- Die Maintenance

- Gating System Optimization

- Lube Application

Education

Associate Degree in Manufacturing Engineering Technology

July 2016

Skills

- Blowing

- Casting Process

- Cycle Monitoring

- Die Maintenance

- Gating System Optimization

- Lube Application

Work Experience

Die Cast Operator (DCO)

- Performed regular maintenance on machines and equipment, including cleaning, lubrication, and minor repairs.

- Collaborated with quality control personnel to inspect and certify cast products to meet industry standards.

- Optimized casting parameters to reduce cycle times and improve production efficiency.

- Developed and implemented standard operating procedures (SOPs) to ensure consistent product quality.

Die Cast Operator (DCO)

- Efficiently operated a variety of die casting machines, including high-pressure, low-pressure, and gravity casting systems.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Prepared and set up dies and molds to ensure dimensional accuracy and product quality.

- Monitored casting processes to detect and correct potential defects in real-time.

Accomplishments

- Developed and implemented a new casting technique that reduced cycle time by 15% and improved casting quality by 20%.

- Trained and mentored new die cast operators, ensuring smooth and efficient transitions into the role.

- Identified and resolved a casting issue that resulted in a significant reduction in scrap rate and cost savings for the company.

- Optimized casting parameters to improve casting yield by 10% and reduce material waste.

- Led a team in implementing a new mold design that increased the production rate by 25%.

Awards

- Received the Die Cast Operator of the Year award from the American Die Casting Institute (ADCI) for exceptional performance and innovation in die casting operations.

- Recognized by the company for consistently exceeding production targets and achieving zero defects in castings.

- Received the Safety Excellence Award for maintaining a spotless safety record throughout the year.

- Honored by the team for exceptional teamwork and dedication to achieving operational goals.

Certificates

- ISO 9001

- AS9100

- IATF 16949

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Cast Operator (DCO)

- Highlight your experience and expertise in die casting operations, showcasing your proficiency in the various aspects of the process.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and quality.

- Emphasize your attention to detail and commitment to safety, highlighting your ability to work meticulously and adhere to industry standards.

- Showcase your teamwork and problem-solving skills, demonstrating your ability to collaborate effectively and find solutions to technical challenges.

Essential Experience Highlights for a Strong Die Cast Operator (DCO) Resume

- Operate and monitor die casting machines to produce metal parts according to specifications.

- Ensure the proper setup and maintenance of dies, molds, and casting equipment.

- Monitor and control casting parameters, such as temperature, pressure, and cycle time, to optimize production efficiency.

- Perform inspections and quality control checks on castings to ensure they meet specifications.

- Identify and troubleshoot machine malfunctions and implement corrective actions to minimize downtime.

- Maintain a clean and organized work area, adhering to safety guidelines and procedures.

- Collaborate with other team members, including engineers, technicians, and supervisors, to improve processes and enhance productivity.

Frequently Asked Questions (FAQ’s) For Die Cast Operator (DCO)

What are the key responsibilities of a Die Cast Operator?

The key responsibilities of a Die Cast Operator include operating and monitoring die casting machines, ensuring proper setup and maintenance of dies and equipment, monitoring casting parameters, performing inspections and quality control checks, troubleshooting machine malfunctions, maintaining a clean and organized work area, and collaborating with other team members to improve processes and enhance productivity.

What are the essential skills required to be a successful Die Cast Operator?

Essential skills for a Die Cast Operator include proficiency in die casting operations, including blowing, casting process, cycle monitoring, die maintenance, gating system optimization, and lube application. Additionally, attention to detail, commitment to safety, teamwork, and problem-solving skills are highly valued.

What are the qualifications needed to become a Die Cast Operator?

While formal education requirements may vary, many Die Cast Operators hold an Associate Degree in Manufacturing Engineering Technology or a related field. Relevant work experience and on-the-job training are also common pathways to this role.

What are the career prospects for Die Cast Operators?

Die Cast Operators can advance their careers by gaining experience and developing specialized skills. Opportunities for promotion to supervisory roles, such as Die Cast Lead or Production Supervisor, are available with experience and demonstrated leadership abilities.

What industries employ Die Cast Operators?

Die Cast Operators are employed in various industries that utilize die casting processes, including automotive, aerospace, consumer products, and construction.

What is the average salary for a Die Cast Operator?

The average salary for a Die Cast Operator can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Die Cast Operator in the United States is approximately $22.50 per hour.

What are the safety precautions that Die Cast Operators must follow?

Die Cast Operators must adhere to strict safety guidelines to minimize the risk of accidents and injuries. These precautions include wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs, and following established procedures for operating and maintaining equipment.