Are you a seasoned General Foundry Worker seeking a new career path? Discover our professionally built General Foundry Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

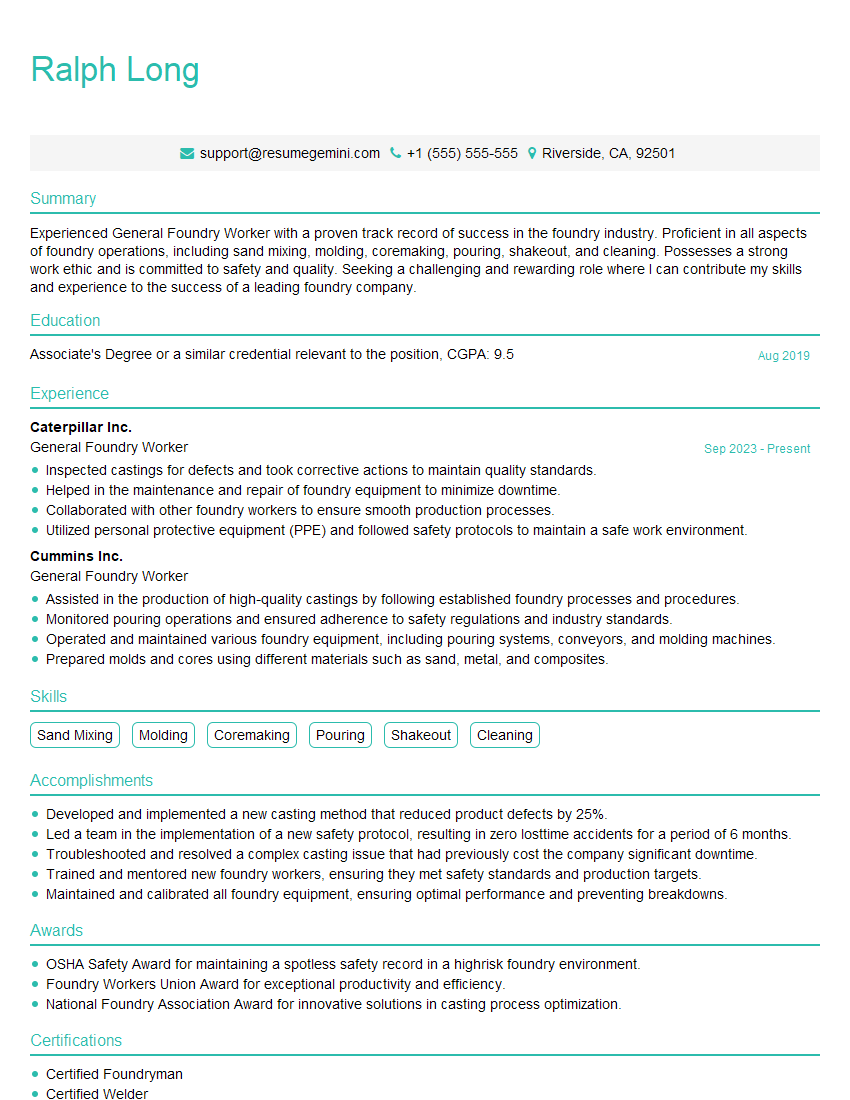

Ralph Long

General Foundry Worker

Summary

Experienced General Foundry Worker with a proven track record of success in the foundry industry. Proficient in all aspects of foundry operations, including sand mixing, molding, coremaking, pouring, shakeout, and cleaning. Possesses a strong work ethic and is committed to safety and quality. Seeking a challenging and rewarding role where I can contribute my skills and experience to the success of a leading foundry company.

Education

Associate’s Degree or a similar credential relevant to the position

August 2019

Skills

- Sand Mixing

- Molding

- Coremaking

- Pouring

- Shakeout

- Cleaning

Work Experience

General Foundry Worker

- Inspected castings for defects and took corrective actions to maintain quality standards.

- Helped in the maintenance and repair of foundry equipment to minimize downtime.

- Collaborated with other foundry workers to ensure smooth production processes.

- Utilized personal protective equipment (PPE) and followed safety protocols to maintain a safe work environment.

General Foundry Worker

- Assisted in the production of high-quality castings by following established foundry processes and procedures.

- Monitored pouring operations and ensured adherence to safety regulations and industry standards.

- Operated and maintained various foundry equipment, including pouring systems, conveyors, and molding machines.

- Prepared molds and cores using different materials such as sand, metal, and composites.

Accomplishments

- Developed and implemented a new casting method that reduced product defects by 25%.

- Led a team in the implementation of a new safety protocol, resulting in zero losttime accidents for a period of 6 months.

- Troubleshooted and resolved a complex casting issue that had previously cost the company significant downtime.

- Trained and mentored new foundry workers, ensuring they met safety standards and production targets.

- Maintained and calibrated all foundry equipment, ensuring optimal performance and preventing breakdowns.

Awards

- OSHA Safety Award for maintaining a spotless safety record in a highrisk foundry environment.

- Foundry Workers Union Award for exceptional productivity and efficiency.

- National Foundry Association Award for innovative solutions in casting process optimization.

Certificates

- Certified Foundryman

- Certified Welder

- Certified Machinist

- Certified Maintenance Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For General Foundry Worker

- Highlight your skills in sand mixing, molding, coremaking, pouring, shakeout, and cleaning in your resume objective or summary.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact on the foundry.

- Tailor your resume and cover letter to each specific job you apply for, highlighting the skills and experiences that are most relevant to the position.

- Network with other foundry professionals and attend industry events to learn about new technologies and trends.

- Stay up-to-date on the latest safety regulations and industry best practices.

Essential Experience Highlights for a Strong General Foundry Worker Resume

- Mix and prepare sand according to specifications to create molds and cores.

- Mold and core using a variety of techniques, including hand molding and machine molding.

- Pour molten metal into molds and cores to create castings.

- Shake out castings from molds and cores after cooling.

- Clean and finish castings to prepare them for further processing or shipment.

- Maintain a clean and organized work area.

- Follow all safety and quality procedures.

Frequently Asked Questions (FAQ’s) For General Foundry Worker

What are the key skills required to be a successful General Foundry Worker?

The key skills required to be a successful General Foundry Worker include sand mixing, molding, coremaking, pouring, shakeout, and cleaning. In addition, General Foundry Workers must have a strong work ethic, be committed to safety, and be able to work independently and as part of a team.

What are the different types of foundries?

There are many different types of foundries, each specializing in a particular type of casting. Some of the most common types of foundries include sand foundries, investment foundries, and permanent mold foundries.

What are the career prospects for General Foundry Workers?

The career prospects for General Foundry Workers are good. The foundry industry is expected to grow in the coming years, and there is a high demand for skilled General Foundry Workers.

What are the safety hazards associated with working in a foundry?

There are a number of safety hazards associated with working in a foundry, including exposure to molten metal, hot and cold temperatures, and hazardous chemicals. Foundries must take steps to protect their workers from these hazards, including providing personal protective equipment and training workers on safety procedures.

What are the different types of castings produced by foundries?

Foundries produce a wide variety of castings, including automotive parts, construction materials, and medical equipment. Castings can be made from a variety of metals, including iron, steel, aluminum, and bronze.

What is the future of the foundry industry?

The future of the foundry industry is bright. The industry is expected to grow in the coming years, and there is a high demand for skilled General Foundry Workers. Foundries are also investing in new technologies to improve efficiency and productivity.