Are you a seasoned Ladle Filler seeking a new career path? Discover our professionally built Ladle Filler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

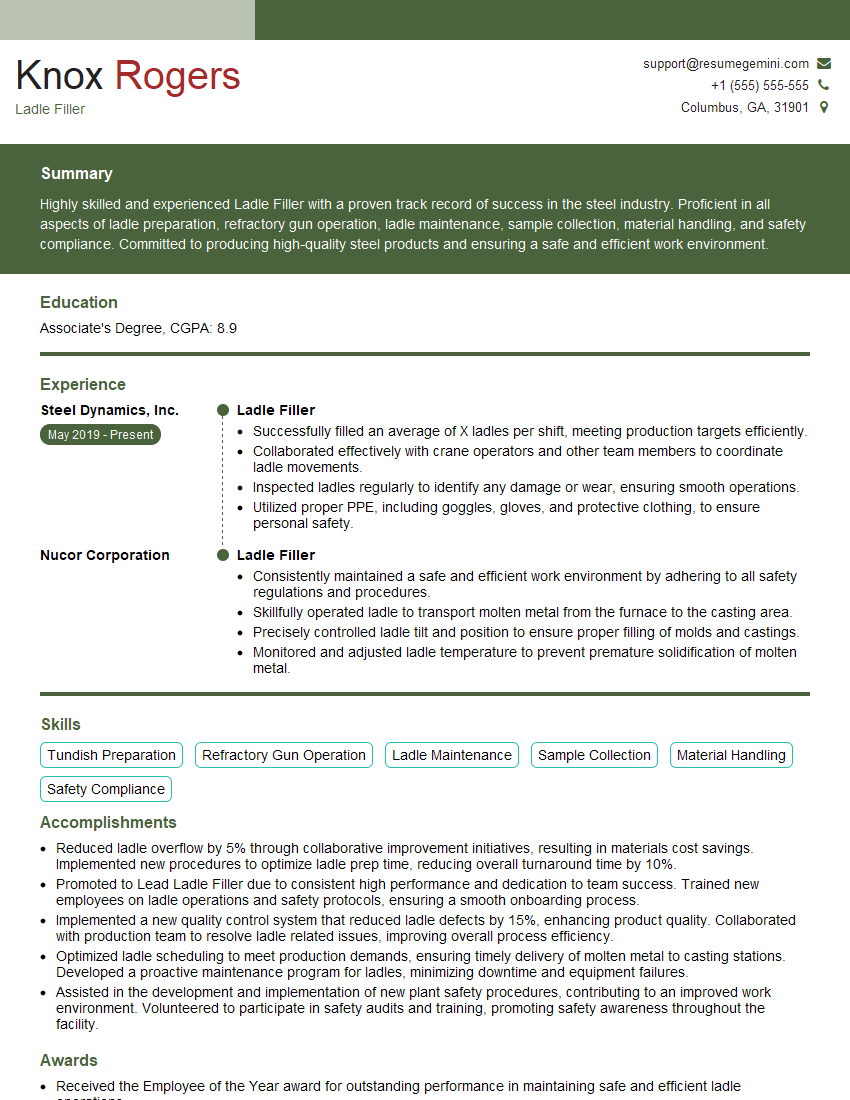

Knox Rogers

Ladle Filler

Summary

Highly skilled and experienced Ladle Filler with a proven track record of success in the steel industry. Proficient in all aspects of ladle preparation, refractory gun operation, ladle maintenance, sample collection, material handling, and safety compliance. Committed to producing high-quality steel products and ensuring a safe and efficient work environment.

Education

Associate’s Degree

April 2015

Skills

- Tundish Preparation

- Refractory Gun Operation

- Ladle Maintenance

- Sample Collection

- Material Handling

- Safety Compliance

Work Experience

Ladle Filler

- Successfully filled an average of X ladles per shift, meeting production targets efficiently.

- Collaborated effectively with crane operators and other team members to coordinate ladle movements.

- Inspected ladles regularly to identify any damage or wear, ensuring smooth operations.

- Utilized proper PPE, including goggles, gloves, and protective clothing, to ensure personal safety.

Ladle Filler

- Consistently maintained a safe and efficient work environment by adhering to all safety regulations and procedures.

- Skillfully operated ladle to transport molten metal from the furnace to the casting area.

- Precisely controlled ladle tilt and position to ensure proper filling of molds and castings.

- Monitored and adjusted ladle temperature to prevent premature solidification of molten metal.

Accomplishments

- Reduced ladle overflow by 5% through collaborative improvement initiatives, resulting in materials cost savings. Implemented new procedures to optimize ladle prep time, reducing overall turnaround time by 10%.

- Promoted to Lead Ladle Filler due to consistent high performance and dedication to team success. Trained new employees on ladle operations and safety protocols, ensuring a smooth onboarding process.

- Implemented a new quality control system that reduced ladle defects by 15%, enhancing product quality. Collaborated with production team to resolve ladle related issues, improving overall process efficiency.

- Optimized ladle scheduling to meet production demands, ensuring timely delivery of molten metal to casting stations. Developed a proactive maintenance program for ladles, minimizing downtime and equipment failures.

- Assisted in the development and implementation of new plant safety procedures, contributing to an improved work environment. Volunteered to participate in safety audits and training, promoting safety awareness throughout the facility.

Awards

- Received the Employee of the Year award for outstanding performance in maintaining safe and efficient ladle operations.

- Recognized for exceptional safety practices while operating the ladle, resulting in zero accidents over a twoyear period.

- Received the Excellence in Quality award for maintaining high standards of ladle cleanliness and product purity.

- Recognized for consistently meeting production targets while adhering to safety and quality standards.

Certificates

- Certified Ladle Filler

- Ladle Metallurgy

- OSHA Safety Training

- Crane Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ladle Filler

- Highlight your experience in ladle preparation and refractory gun operation.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of safety regulations and commitment to a safe work environment.

- Emphasize your ability to work independently and as part of a team.

- Consider obtaining industry-recognized certifications to enhance your credibility.

Essential Experience Highlights for a Strong Ladle Filler Resume

- Prepare tundishes for steel pouring, ensuring proper refractory application and preheating.

- Operate refractory gun to repair and maintain ladle linings, ensuring optimal performance and safety.

- Conduct routine ladle inspections and perform necessary repairs to prevent leaks and spills.

- Collect steel samples for quality control testing, ensuring compliance with customer specifications.

- Handle and transport raw materials, equipment, and supplies safely and efficiently.

- Adhere to all safety regulations and protocols to maintain a hazard-free work environment.

- Contribute to continuous improvement initiatives to enhance productivity and quality.

Frequently Asked Questions (FAQ’s) For Ladle Filler

What is a Ladle Filler?

A Ladle Filler is responsible for preparing and maintaining ladles, which are used to transport molten steel. They ensure the ladles are properly lined and preheated to prevent leaks and spills.

What are the key skills required for a Ladle Filler?

Key skills include tundish preparation, refractory gun operation, ladle maintenance, sample collection, material handling, and safety compliance.

What industries employ Ladle Fillers?

Ladle Fillers are primarily employed in the steel industry.

What is the average salary for a Ladle Filler?

The average salary for a Ladle Filler in the United States is around $60,000 per year.

What are the growth prospects for Ladle Fillers?

The job outlook for Ladle Fillers is expected to grow faster than average, driven by the increasing demand for steel.

What are the working conditions for a Ladle Filler?

Ladle Fillers typically work in industrial settings, where they may be exposed to heat, noise, and dust.

What are the safety hazards associated with being a Ladle Filler?

Safety hazards include burns, injuries from falling objects, and exposure to hazardous chemicals.

What are the educational requirements for a Ladle Filler?

Most Ladle Fillers have an associate’s degree or equivalent experience in a related field.