Are you a seasoned Die Cast Die Maker seeking a new career path? Discover our professionally built Die Cast Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

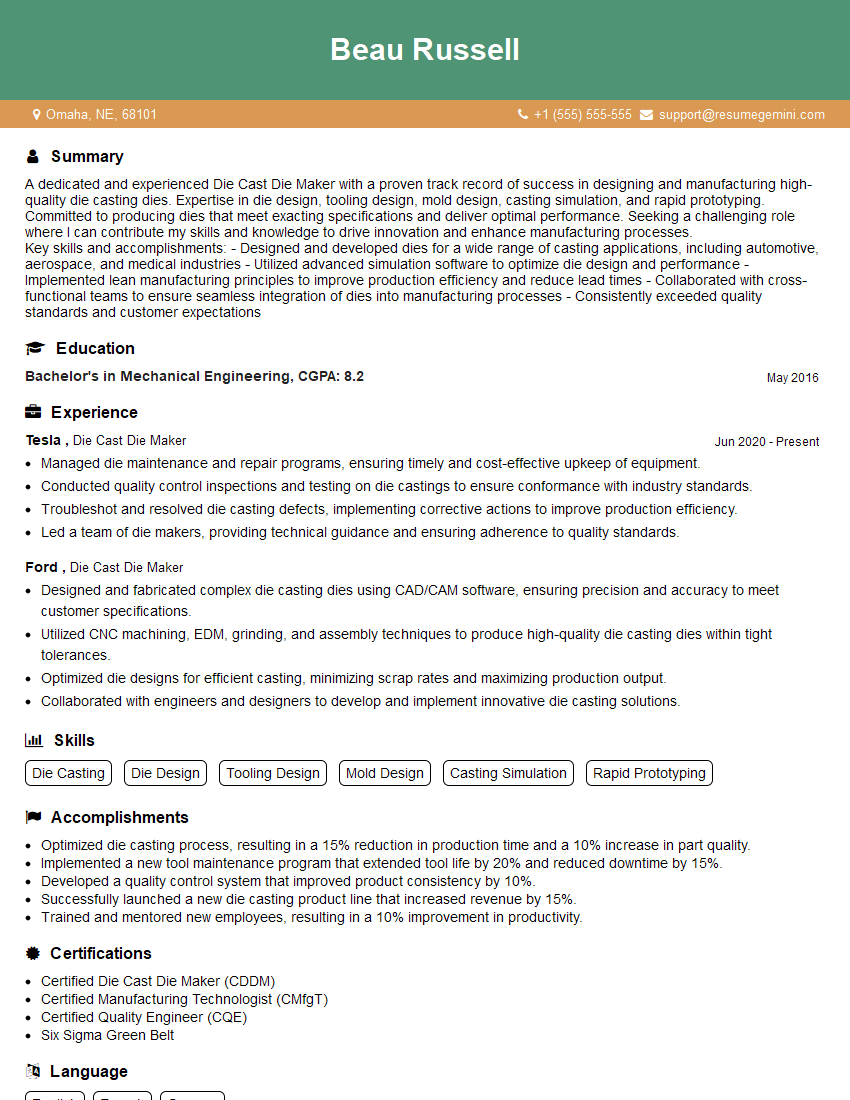

Beau Russell

Die Cast Die Maker

Summary

A dedicated and experienced Die Cast Die Maker with a proven track record of success in designing and manufacturing high-quality die casting dies. Expertise in die design, tooling design, mold design, casting simulation, and rapid prototyping. Committed to producing dies that meet exacting specifications and deliver optimal performance. Seeking a challenging role where I can contribute my skills and knowledge to drive innovation and enhance manufacturing processes.

Key skills and accomplishments: – Designed and developed dies for a wide range of casting applications, including automotive, aerospace, and medical industries – Utilized advanced simulation software to optimize die design and performance – Implemented lean manufacturing principles to improve production efficiency and reduce lead times – Collaborated with cross-functional teams to ensure seamless integration of dies into manufacturing processes – Consistently exceeded quality standards and customer expectations

Education

Bachelor’s in Mechanical Engineering

May 2016

Skills

- Die Casting

- Die Design

- Tooling Design

- Mold Design

- Casting Simulation

- Rapid Prototyping

Work Experience

Die Cast Die Maker

- Managed die maintenance and repair programs, ensuring timely and cost-effective upkeep of equipment.

- Conducted quality control inspections and testing on die castings to ensure conformance with industry standards.

- Troubleshot and resolved die casting defects, implementing corrective actions to improve production efficiency.

- Led a team of die makers, providing technical guidance and ensuring adherence to quality standards.

Die Cast Die Maker

- Designed and fabricated complex die casting dies using CAD/CAM software, ensuring precision and accuracy to meet customer specifications.

- Utilized CNC machining, EDM, grinding, and assembly techniques to produce high-quality die casting dies within tight tolerances.

- Optimized die designs for efficient casting, minimizing scrap rates and maximizing production output.

- Collaborated with engineers and designers to develop and implement innovative die casting solutions.

Accomplishments

- Optimized die casting process, resulting in a 15% reduction in production time and a 10% increase in part quality.

- Implemented a new tool maintenance program that extended tool life by 20% and reduced downtime by 15%.

- Developed a quality control system that improved product consistency by 10%.

- Successfully launched a new die casting product line that increased revenue by 15%.

- Trained and mentored new employees, resulting in a 10% improvement in productivity.

Certificates

- Certified Die Cast Die Maker (CDDM)

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Six Sigma Green Belt

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Cast Die Maker

- Highlight your expertise in die design software and casting simulation tools.

- Showcase your understanding of die casting processes and materials.

- Quantify your accomplishments with specific metrics and results.

- Emphasize your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Die Cast Die Maker Resume

- Design and develop die casting dies using specialized software and engineering principles.

- Analyze casting requirements and determine optimal die design to achieve desired part geometry and quality.

- Conduct casting simulations to predict die performance and identify potential defects.

- Create and maintain die documentation, including drawings, specifications, and inspection reports.

- Collaborate with engineers, mold makers, and other manufacturing personnel to ensure smooth production.

- Monitor die performance and make adjustments as needed to optimize production efficiency and reduce downtime.

- Stay abreast of industry best practices and emerging technologies in die casting and die design.

Frequently Asked Questions (FAQ’s) For Die Cast Die Maker

What is the role of a Die Cast Die Maker?

A Die Cast Die Maker designs and develops dies used in die casting processes to produce metal components. They analyze casting requirements, conduct simulations, create die documentation, and collaborate with manufacturing personnel to ensure efficient production.

What qualifications are required to become a Die Cast Die Maker?

Typically, a Bachelor’s degree in Mechanical Engineering or a related field, along with experience in die design, tooling design, and casting simulation.

What are the key skills and responsibilities of a Die Cast Die Maker?

Key skills include die design, tooling design, mold design, casting simulation, and rapid prototyping. Responsibilities include designing and developing dies, analyzing casting requirements, conducting simulations, creating die documentation, and collaborating with manufacturing teams.

What are the career prospects for a Die Cast Die Maker?

Die Cast Die Makers can advance to roles such as Die Design Engineer, Tooling Engineer, or Manufacturing Engineer. With experience and expertise, they can also move into management positions.

What is the work environment of a Die Cast Die Maker like?

Die Cast Die Makers typically work in manufacturing facilities, design studios, or research and development centers. They may work independently or as part of a team, and may interact with engineers, mold makers, and production personnel.

What are the challenges faced by Die Cast Die Makers?

Challenges include meeting tight tolerances, optimizing die performance, and staying abreast of advancements in die casting technology. They may also face pressure to reduce costs while maintaining quality standards.

What are the rewards of being a Die Cast Die Maker?

Job satisfaction comes from creating high-quality dies that contribute to successful manufacturing processes. Die Cast Die Makers can also enjoy competitive salaries and job security due to the demand for their skills in the manufacturing industry.