Are you a seasoned Blow Mold Operator seeking a new career path? Discover our professionally built Blow Mold Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

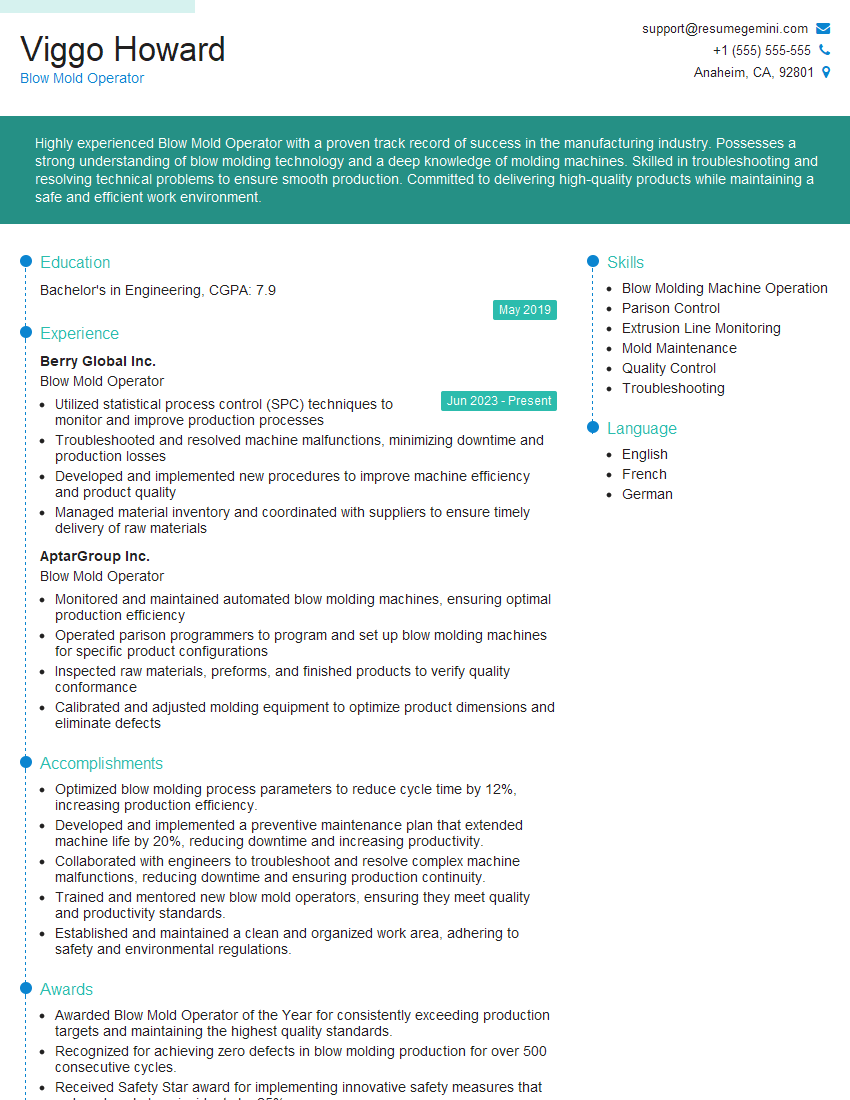

Viggo Howard

Blow Mold Operator

Summary

Highly experienced Blow Mold Operator with a proven track record of success in the manufacturing industry. Possesses a strong understanding of blow molding technology and a deep knowledge of molding machines. Skilled in troubleshooting and resolving technical problems to ensure smooth production. Committed to delivering high-quality products while maintaining a safe and efficient work environment.

Education

Bachelor’s in Engineering

May 2019

Skills

- Blow Molding Machine Operation

- Parison Control

- Extrusion Line Monitoring

- Mold Maintenance

- Quality Control

- Troubleshooting

Work Experience

Blow Mold Operator

- Utilized statistical process control (SPC) techniques to monitor and improve production processes

- Troubleshooted and resolved machine malfunctions, minimizing downtime and production losses

- Developed and implemented new procedures to improve machine efficiency and product quality

- Managed material inventory and coordinated with suppliers to ensure timely delivery of raw materials

Blow Mold Operator

- Monitored and maintained automated blow molding machines, ensuring optimal production efficiency

- Operated parison programmers to program and set up blow molding machines for specific product configurations

- Inspected raw materials, preforms, and finished products to verify quality conformance

- Calibrated and adjusted molding equipment to optimize product dimensions and eliminate defects

Accomplishments

- Optimized blow molding process parameters to reduce cycle time by 12%, increasing production efficiency.

- Developed and implemented a preventive maintenance plan that extended machine life by 20%, reducing downtime and increasing productivity.

- Collaborated with engineers to troubleshoot and resolve complex machine malfunctions, reducing downtime and ensuring production continuity.

- Trained and mentored new blow mold operators, ensuring they meet quality and productivity standards.

- Established and maintained a clean and organized work area, adhering to safety and environmental regulations.

Awards

- Awarded Blow Mold Operator of the Year for consistently exceeding production targets and maintaining the highest quality standards.

- Recognized for achieving zero defects in blow molding production for over 500 consecutive cycles.

- Received Safety Star award for implementing innovative safety measures that reduced workplace incidents by 25%.

Certificates

- Certified Blow Mold Operator (CBMO)

- Certified Plastic Processing Technician (CPPT)

- Society of Plastics Engineers (SPE) Certification

- OSHA 30-Hour General Industry Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Blow Mold Operator

- Highlight your technical skills and experience in blow molding operations.

- Showcase your knowledge of machine maintenance and troubleshooting.

- Emphasize your attention to detail and commitment to quality.

- Include quantifiable results to demonstrate your impact on production efficiency.

Essential Experience Highlights for a Strong Blow Mold Operator Resume

- Operate blow molding machines to produce plastic products according to specifications.

- Control parison thickness and dimensions to ensure the quality of the final product.

- Monitor extrusion lines for any abnormalities and take corrective actions as needed.

- Perform preventive maintenance on molds and equipment to minimize downtime.

- Inspect finished products for defects and ensure adherence to quality standards.

- Troubleshoot and resolve machine malfunctions and production issues to maintain optimal efficiency.

- Maintain a clean and organized work area to promote safety and productivity.

Frequently Asked Questions (FAQ’s) For Blow Mold Operator

What are the key skills required to be a Blow Mold Operator?

Key skills include Blow Molding Machine Operation, Parison Control, Extrusion Line Monitoring, Mold Maintenance, Quality Control, and Troubleshooting.

What is the average salary for a Blow Mold Operator?

The average salary for a Blow Mold Operator in the United States is around $50,000 per year.

What are the career prospects for a Blow Mold Operator?

Blow Mold Operators with experience and expertise can advance to supervisory or management roles in the manufacturing industry.

What is the work environment like for a Blow Mold Operator?

Blow Mold Operators typically work in manufacturing facilities, operating machinery in a production environment.

What are the physical demands of being a Blow Mold Operator?

The job requires standing for long periods, lifting heavy objects, and working in a noisy environment.

Is there a high demand for Blow Mold Operators?

Yes, there is a growing demand for skilled Blow Mold Operators due to the increasing use of plastic products in various industries.

How can I become a Blow Mold Operator?

To become a Blow Mold Operator, you can complete a training program or gain experience as a machine operator in the manufacturing industry.