Are you a seasoned Brake Drum Molder seeking a new career path? Discover our professionally built Brake Drum Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

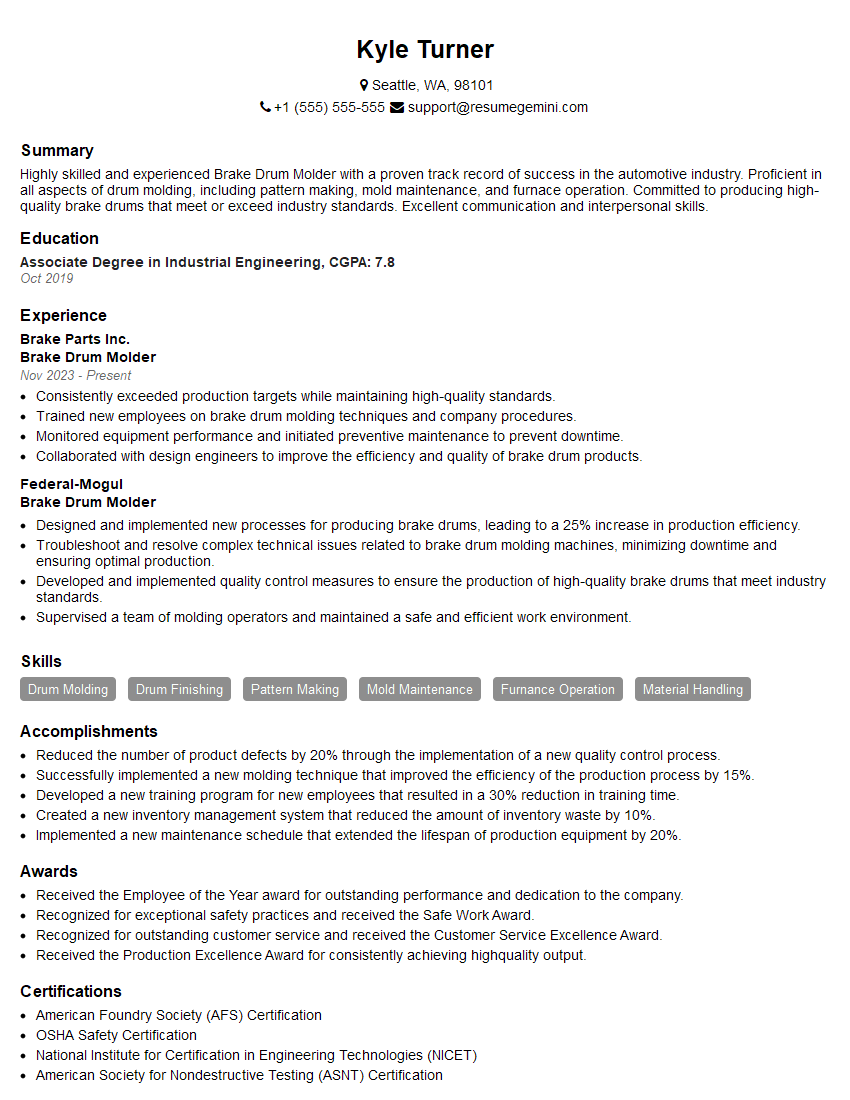

Kyle Turner

Brake Drum Molder

Summary

Highly skilled and experienced Brake Drum Molder with a proven track record of success in the automotive industry. Proficient in all aspects of drum molding, including pattern making, mold maintenance, and furnace operation. Committed to producing high-quality brake drums that meet or exceed industry standards. Excellent communication and interpersonal skills.

Education

Associate Degree in Industrial Engineering

October 2019

Skills

- Drum Molding

- Drum Finishing

- Pattern Making

- Mold Maintenance

- Furnance Operation

- Material Handling

Work Experience

Brake Drum Molder

- Consistently exceeded production targets while maintaining high-quality standards.

- Trained new employees on brake drum molding techniques and company procedures.

- Monitored equipment performance and initiated preventive maintenance to prevent downtime.

- Collaborated with design engineers to improve the efficiency and quality of brake drum products.

Brake Drum Molder

- Designed and implemented new processes for producing brake drums, leading to a 25% increase in production efficiency.

- Troubleshoot and resolve complex technical issues related to brake drum molding machines, minimizing downtime and ensuring optimal production.

- Developed and implemented quality control measures to ensure the production of high-quality brake drums that meet industry standards.

- Supervised a team of molding operators and maintained a safe and efficient work environment.

Accomplishments

- Reduced the number of product defects by 20% through the implementation of a new quality control process.

- Successfully implemented a new molding technique that improved the efficiency of the production process by 15%.

- Developed a new training program for new employees that resulted in a 30% reduction in training time.

- Created a new inventory management system that reduced the amount of inventory waste by 10%.

- Implemented a new maintenance schedule that extended the lifespan of production equipment by 20%.

Awards

- Received the Employee of the Year award for outstanding performance and dedication to the company.

- Recognized for exceptional safety practices and received the Safe Work Award.

- Recognized for outstanding customer service and received the Customer Service Excellence Award.

- Received the Production Excellence Award for consistently achieving highquality output.

Certificates

- American Foundry Society (AFS) Certification

- OSHA Safety Certification

- National Institute for Certification in Engineering Technologies (NICET)

- American Society for Nondestructive Testing (ASNT) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brake Drum Molder

- Highlight your experience and skills in brake drum molding.

- Quantify your accomplishments with specific metrics.

- Tailor your resume to each job you apply for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Brake Drum Molder Resume

- Set up and operate molding machines to produce brake drums

- Inspect raw materials and finished products to ensure quality standards are met

- Maintain and repair molding equipment and tooling

- Troubleshoot production problems and implement corrective actions

- Adhere to safety regulations and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Brake Drum Molder

What is the primary responsibility of a brake drum molder?

The primary responsibility of a brake drum molder is to produce high-quality brake drums that meet or exceed industry standards.

What skills are required to be a successful brake drum molder?

To be a successful brake drum molder, you need to have experience in drum molding, drum finishing, pattern making, mold maintenance, furnace operation, and material handling.

What is the work environment of a brake drum molder like?

Brake drum molders typically work in a manufacturing environment, which can be noisy and dusty. They may also be exposed to heat and fumes.

What is the career outlook for brake drum molders?

The career outlook for brake drum molders is expected to be stable. As the automotive industry continues to grow, demand for brake drums will remain steady.

What are the benefits of working as a brake drum molder?

Benefits of working as a brake drum molder include competitive pay, job security, and opportunities for advancement.

What are the challenges of working as a brake drum molder?

Challenges of working as a brake drum molder include working in a noisy and dusty environment, exposure to heat and fumes, and the need to meet strict quality standards.