Are you a seasoned Casting Molder seeking a new career path? Discover our professionally built Casting Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

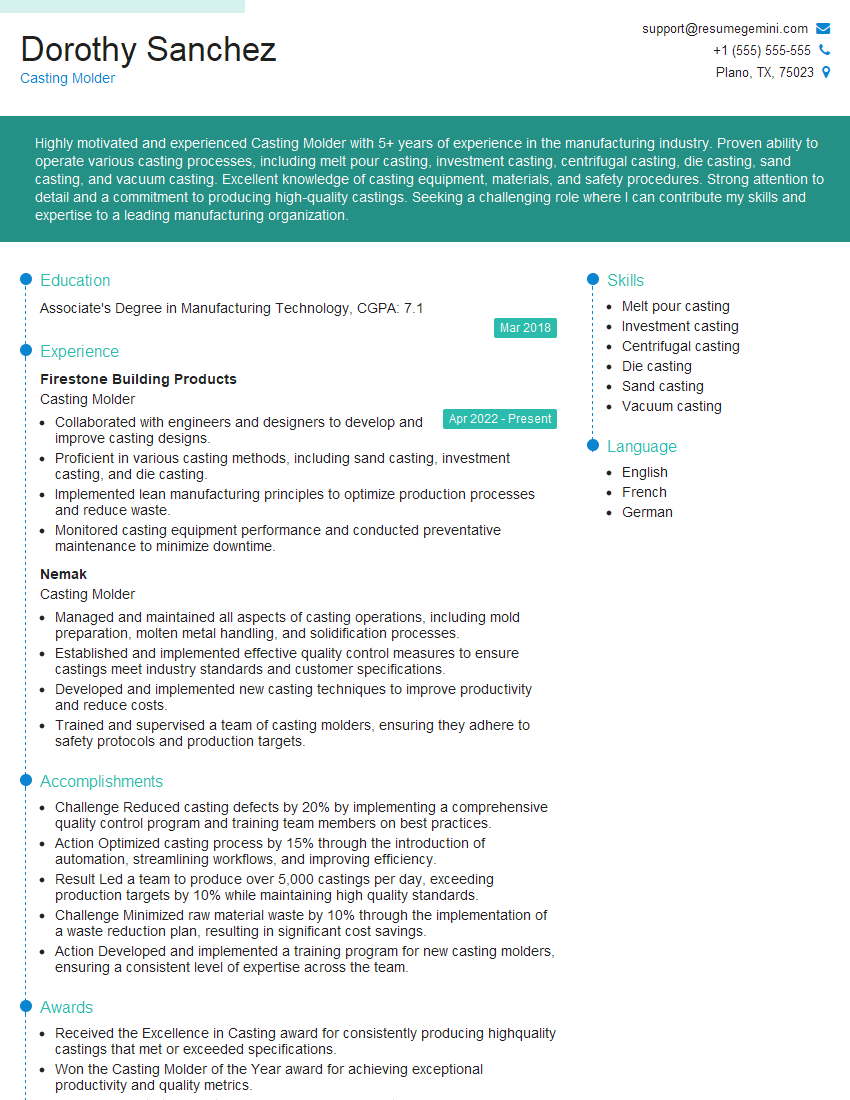

Dorothy Sanchez

Casting Molder

Summary

Highly motivated and experienced Casting Molder with 5+ years of experience in the manufacturing industry. Proven ability to operate various casting processes, including melt pour casting, investment casting, centrifugal casting, die casting, sand casting, and vacuum casting. Excellent knowledge of casting equipment, materials, and safety procedures. Strong attention to detail and a commitment to producing high-quality castings. Seeking a challenging role where I can contribute my skills and expertise to a leading manufacturing organization.

Education

Associate’s Degree in Manufacturing Technology

March 2018

Skills

- Melt pour casting

- Investment casting

- Centrifugal casting

- Die casting

- Sand casting

- Vacuum casting

Work Experience

Casting Molder

- Collaborated with engineers and designers to develop and improve casting designs.

- Proficient in various casting methods, including sand casting, investment casting, and die casting.

- Implemented lean manufacturing principles to optimize production processes and reduce waste.

- Monitored casting equipment performance and conducted preventative maintenance to minimize downtime.

Casting Molder

- Managed and maintained all aspects of casting operations, including mold preparation, molten metal handling, and solidification processes.

- Established and implemented effective quality control measures to ensure castings meet industry standards and customer specifications.

- Developed and implemented new casting techniques to improve productivity and reduce costs.

- Trained and supervised a team of casting molders, ensuring they adhere to safety protocols and production targets.

Accomplishments

- Challenge Reduced casting defects by 20% by implementing a comprehensive quality control program and training team members on best practices.

- Action Optimized casting process by 15% through the introduction of automation, streamlining workflows, and improving efficiency.

- Result Led a team to produce over 5,000 castings per day, exceeding production targets by 10% while maintaining high quality standards.

- Challenge Minimized raw material waste by 10% through the implementation of a waste reduction plan, resulting in significant cost savings.

- Action Developed and implemented a training program for new casting molders, ensuring a consistent level of expertise across the team.

Awards

- Received the Excellence in Casting award for consistently producing highquality castings that met or exceeded specifications.

- Won the Casting Molder of the Year award for achieving exceptional productivity and quality metrics.

- Recognized with the Safety Champion Award for maintaining an impeccable safety record and promoting workplace safety initiatives.

Certificates

- Certified Casting Molder (CCM)

- Certified Investment Caster (CIC)

- Certified Foundryman (CF)

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Casting Molder

- Highlight your hands-on experience with different casting techniques.

- Showcase your ability to read and interpret technical drawings and specifications.

- Emphasize your understanding of casting materials, their properties, and applications.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the production process.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role you are applying for.

Essential Experience Highlights for a Strong Casting Molder Resume

- Operate and maintain casting equipment, including furnaces, molds, and casting machines

- Select and prepare raw materials according to specifications

- Monitor casting processes to ensure adherence to quality standards

- Perform quality control checks on castings to identify and correct defects

- Troubleshoot and resolve casting issues to maintain efficient production

- Maintain a clean and organized work area in compliance with safety regulations

- Collaborate with engineers and production team members to optimize casting processes

Frequently Asked Questions (FAQ’s) For Casting Molder

What is the role of a Casting Molder?

Casting Molders create metal or plastic objects by pouring molten material into molds and allowing it to solidify. They are responsible for operating casting equipment, preparing and selecting materials, and ensuring that castings meet quality standards.

What are the different types of casting processes?

There are various casting processes used in industries, including sand casting, investment casting, die casting, centrifugal casting, vacuum casting, and melt pour casting.

What are the key skills required to be a successful Casting Molder?

Successful Casting Molders possess a combination of technical skills, such as operating casting equipment, understanding casting processes, and knowledge of materials, along with strong attention to detail, problem-solving abilities, and a commitment to safety.

What industries employ Casting Molders?

Casting Molders are employed in various industries that utilize metal or plastic castings, including automotive, aerospace, construction, and manufacturing.

What is the career path for Casting Molders?

With experience and additional training, Casting Molders can advance to supervisory or management roles within the manufacturing industry.

What are the safety precautions to consider in casting operations?

Casting operations involve working with molten materials and heavy equipment, so adhering to safety guidelines, wearing appropriate protective gear, and maintaining a clean and organized work area are crucial.

How can I improve my casting skills?

To enhance your casting skills, consider pursuing additional training or certification programs, staying updated with industry best practices, and seeking opportunities to practice and improve your techniques.