Are you a seasoned Compression Molding Machine Setter seeking a new career path? Discover our professionally built Compression Molding Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

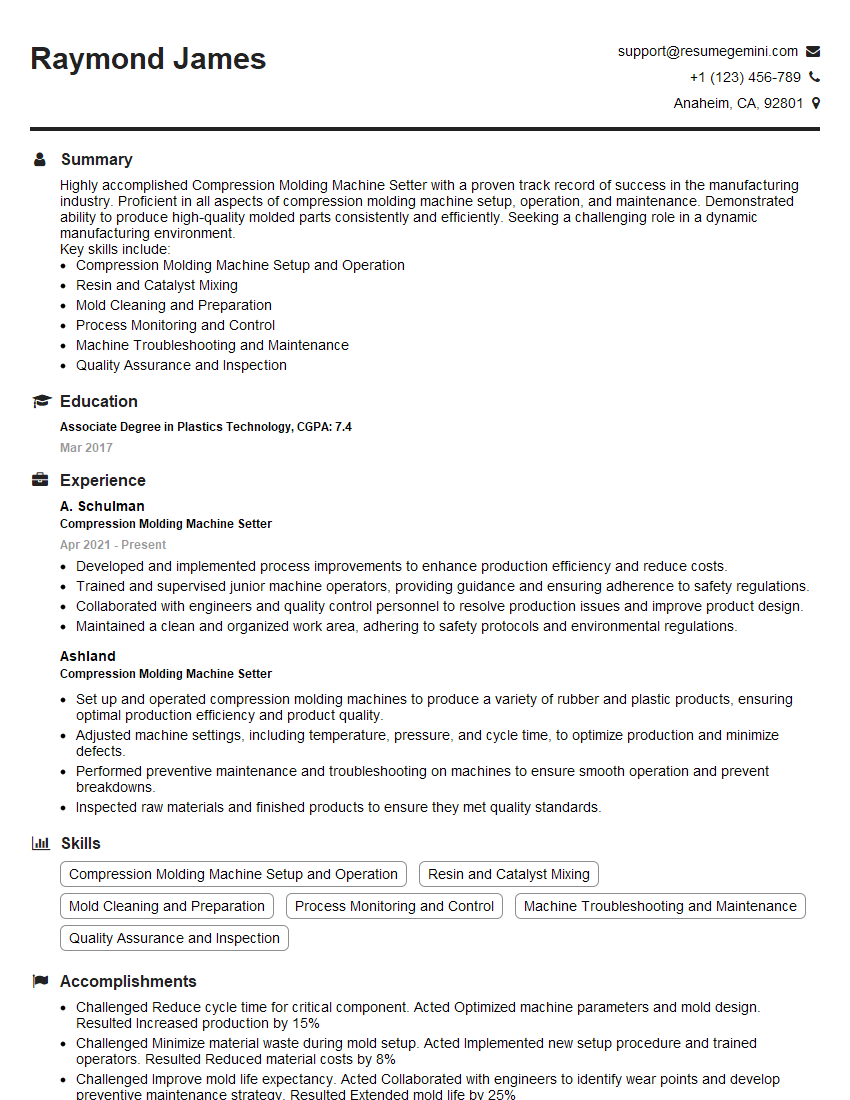

Raymond James

Compression Molding Machine Setter

Summary

Highly accomplished Compression Molding Machine Setter with a proven track record of success in the manufacturing industry. Proficient in all aspects of compression molding machine setup, operation, and maintenance. Demonstrated ability to produce high-quality molded parts consistently and efficiently. Seeking a challenging role in a dynamic manufacturing environment.

Key skills include:

- Compression Molding Machine Setup and Operation

- Resin and Catalyst Mixing

- Mold Cleaning and Preparation

- Process Monitoring and Control

- Machine Troubleshooting and Maintenance

- Quality Assurance and Inspection

Education

Associate Degree in Plastics Technology

March 2017

Skills

- Compression Molding Machine Setup and Operation

- Resin and Catalyst Mixing

- Mold Cleaning and Preparation

- Process Monitoring and Control

- Machine Troubleshooting and Maintenance

- Quality Assurance and Inspection

Work Experience

Compression Molding Machine Setter

- Developed and implemented process improvements to enhance production efficiency and reduce costs.

- Trained and supervised junior machine operators, providing guidance and ensuring adherence to safety regulations.

- Collaborated with engineers and quality control personnel to resolve production issues and improve product design.

- Maintained a clean and organized work area, adhering to safety protocols and environmental regulations.

Compression Molding Machine Setter

- Set up and operated compression molding machines to produce a variety of rubber and plastic products, ensuring optimal production efficiency and product quality.

- Adjusted machine settings, including temperature, pressure, and cycle time, to optimize production and minimize defects.

- Performed preventive maintenance and troubleshooting on machines to ensure smooth operation and prevent breakdowns.

- Inspected raw materials and finished products to ensure they met quality standards.

Accomplishments

- Challenged Reduce cycle time for critical component. Acted Optimized machine parameters and mold design. Resulted Increased production by 15%

- Challenged Minimize material waste during mold setup. Acted Implemented new setup procedure and trained operators. Resulted Reduced material costs by 8%

- Challenged Improve mold life expectancy. Acted Collaborated with engineers to identify wear points and develop preventive maintenance strategy. Resulted Extended mold life by 25%

- Challenged Enhance machine safety. Acted Conducted thorough risk assessment and implemented safety upgrades. Resulted Eliminated potential hazards and ensured operator safety

- Challenged Reduce energy consumption. Acted Installed energy monitoring system and optimized machine settings. Resulted Decreased energy usage by 10%

Awards

- Recognized for achieving 98% production efficiency, exceeding industry benchmark by 3%

- Awarded Employee of the Month for consistently maintaining defect rates below 0.5%

- Received Golden Wrench Award for innovative suggestion that improved machine uptime by 12%

Certificates

- Certified Compression Molding Technician (CMT)

- Certified Manufacturing Technician (CMfgT)

- Plastics Processing Technician (PPT)

- Tooling and Fixturing Fundamentals (TFF)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Compression Molding Machine Setter

Highlight your technical skills.

Compression molding machine setters need to have a strong understanding of the equipment they operate. Be sure to list your skills and experience in setting up, operating, and maintaining compression molding machines.Quantify your accomplishments.

When describing your experience, be sure to quantify your accomplishments whenever possible. For example, you could say that you “reduced downtime by 15%” or “increased production output by 10%”.Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. Some relevant keywords for compression molding machine setters include: “compression molding”, “resin mixing”, “mold cleaning”, “process monitoring”, and “quality assurance”.Proofread your resume carefully.

Before you submit your resume, be sure to proofread it carefully for any errors. Typos and other mistakes can make you look unprofessional and could cost you the job.

Essential Experience Highlights for a Strong Compression Molding Machine Setter Resume

- Set up and operate compression molding machines according to specifications.

- Mix and prepare resin and catalyst according to established ratios.

- Clean and prepare molds prior to production.

- Monitor and control the molding process to ensure optimal part quality.

- Troubleshoot and maintain molding machines to minimize downtime.

- Perform quality assurance checks on molded parts to ensure they meet specifications.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Compression Molding Machine Setter

What is a compression molding machine setter?

A compression molding machine setter is responsible for setting up, operating, and maintaining compression molding machines. They mix and prepare resin and catalyst, clean and prepare molds, and monitor and control the molding process to ensure optimal part quality.

What are the qualifications for a compression molding machine setter?

Compression molding machine setters typically need a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in plastics technology or a related field.

What are the key skills for a compression molding machine setter?

Key skills for a compression molding machine setter include:

- Compression molding machine setup and operation

- Resin and catalyst mixing

- Mold cleaning and preparation

- Process monitoring and control

- Machine troubleshooting and maintenance

- Quality assurance and inspection

What is the average salary for a compression molding machine setter?

The average salary for a compression molding machine setter in the United States is $25.50 per hour.

What is the job outlook for compression molding machine setters?

The job outlook for compression molding machine setters is expected to be good over the next few years. The demand for compression molded parts is expected to grow as the manufacturing industry continues to expand.

What are the benefits of working as a compression molding machine setter?

Benefits of working as a compression molding machine setter include:

- Competitive salary and benefits

- Opportunities for advancement

- Job security

- Variety of work

- Chance to make a difference