Are you a seasoned Compression Molding Machine Operator seeking a new career path? Discover our professionally built Compression Molding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

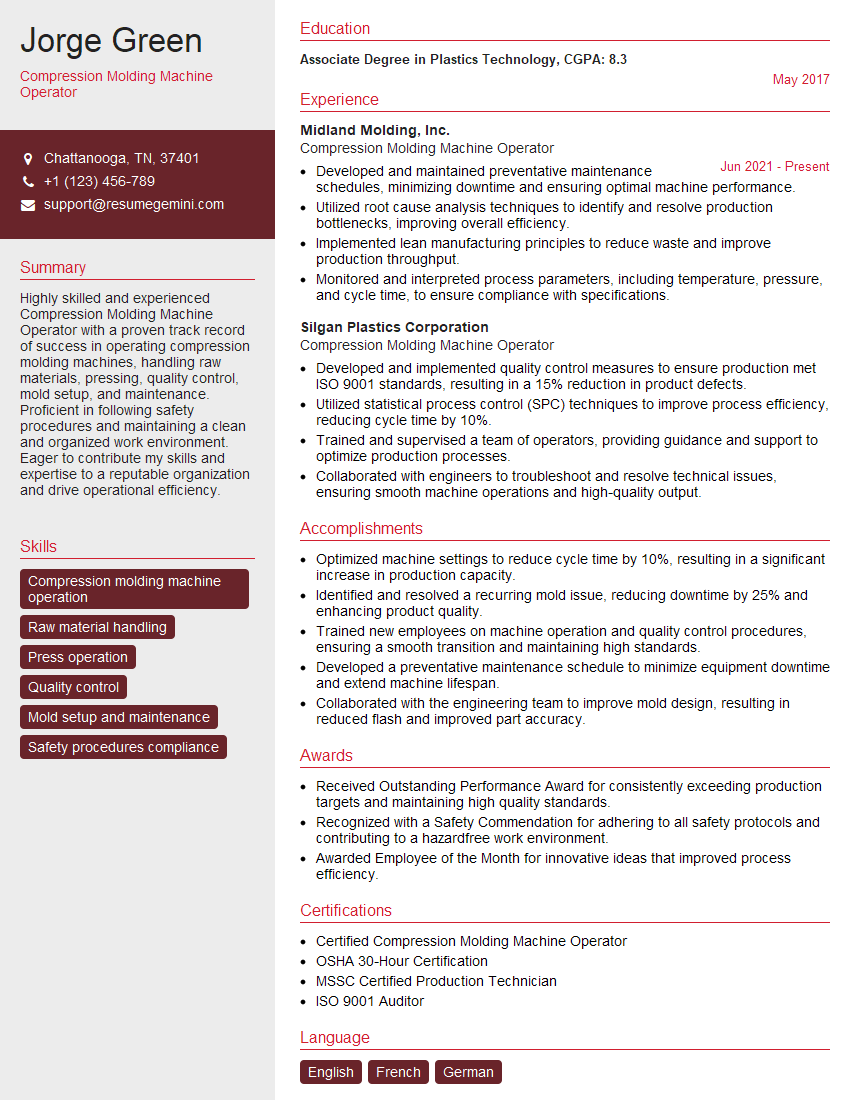

Jorge Green

Compression Molding Machine Operator

Summary

Highly skilled and experienced Compression Molding Machine Operator with a proven track record of success in operating compression molding machines, handling raw materials, pressing, quality control, mold setup, and maintenance. Proficient in following safety procedures and maintaining a clean and organized work environment. Eager to contribute my skills and expertise to a reputable organization and drive operational efficiency.

Education

Associate Degree in Plastics Technology

May 2017

Skills

- Compression molding machine operation

- Raw material handling

- Press operation

- Quality control

- Mold setup and maintenance

- Safety procedures compliance

Work Experience

Compression Molding Machine Operator

- Developed and maintained preventative maintenance schedules, minimizing downtime and ensuring optimal machine performance.

- Utilized root cause analysis techniques to identify and resolve production bottlenecks, improving overall efficiency.

- Implemented lean manufacturing principles to reduce waste and improve production throughput.

- Monitored and interpreted process parameters, including temperature, pressure, and cycle time, to ensure compliance with specifications.

Compression Molding Machine Operator

- Developed and implemented quality control measures to ensure production met ISO 9001 standards, resulting in a 15% reduction in product defects.

- Utilized statistical process control (SPC) techniques to improve process efficiency, reducing cycle time by 10%.

- Trained and supervised a team of operators, providing guidance and support to optimize production processes.

- Collaborated with engineers to troubleshoot and resolve technical issues, ensuring smooth machine operations and high-quality output.

Accomplishments

- Optimized machine settings to reduce cycle time by 10%, resulting in a significant increase in production capacity.

- Identified and resolved a recurring mold issue, reducing downtime by 25% and enhancing product quality.

- Trained new employees on machine operation and quality control procedures, ensuring a smooth transition and maintaining high standards.

- Developed a preventative maintenance schedule to minimize equipment downtime and extend machine lifespan.

- Collaborated with the engineering team to improve mold design, resulting in reduced flash and improved part accuracy.

Awards

- Received Outstanding Performance Award for consistently exceeding production targets and maintaining high quality standards.

- Recognized with a Safety Commendation for adhering to all safety protocols and contributing to a hazardfree work environment.

- Awarded Employee of the Month for innovative ideas that improved process efficiency.

Certificates

- Certified Compression Molding Machine Operator

- OSHA 30-Hour Certification

- MSSC Certified Production Technician

- ISO 9001 Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Compression Molding Machine Operator

- Highlight your experience and skills in operating compression molding machines.

- Showcase your understanding of raw material handling, press operation, quality control, and mold setup and maintenance.

- Emphasize your adherence to safety procedures and ability to maintain a clean and organized work environment.

- Demonstrate your problem-solving skills and ability to work effectively in a team.

Essential Experience Highlights for a Strong Compression Molding Machine Operator Resume

- Operate compression molding machines to produce plastic and rubber products according to specifications.

- Handle raw materials, including loading and unloading materials into the machine.

- Press the materials to form desired shapes and dimensions.

- Inspect products for defects and ensure they meet quality standards.

- Set up and maintain molds, including cleaning, adjusting, and repairing as needed.

- Follow safety procedures and maintain a clean and organized work environment.

- Collaborate with team members to optimize production processes and troubleshoot any issues.

Frequently Asked Questions (FAQ’s) For Compression Molding Machine Operator

What is the primary role of a Compression Molding Machine Operator?

The primary role of a Compression Molding Machine Operator is to operate compression molding machines to produce plastic and rubber products according to specifications, ensuring quality and efficiency.

What skills are essential for a Compression Molding Machine Operator?

Essential skills for a Compression Molding Machine Operator include machine operation, raw material handling, press operation, quality control, mold setup and maintenance, and safety compliance.

What are the typical working conditions for a Compression Molding Machine Operator?

Compression Molding Machine Operators typically work in manufacturing facilities, operating machinery in a fast-paced and often noisy environment. Safety gear and attention to detail are crucial.

What qualifications are required to become a Compression Molding Machine Operator?

While formal education may vary, many Compression Molding Machine Operators hold an Associate Degree in Plastics Technology or a related field, along with relevant hands-on experience.

What is the career outlook for Compression Molding Machine Operators?

The career outlook for Compression Molding Machine Operators is expected to be positive due to the increasing demand for plastic and rubber products in various industries.

What are the key responsibilities of a Compression Molding Machine Operator?

Key responsibilities include operating compression molding machines, handling raw materials, pressing, quality control, mold setup and maintenance, safety compliance, and optimizing production processes.