Are you a seasoned Molding Process Technician seeking a new career path? Discover our professionally built Molding Process Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

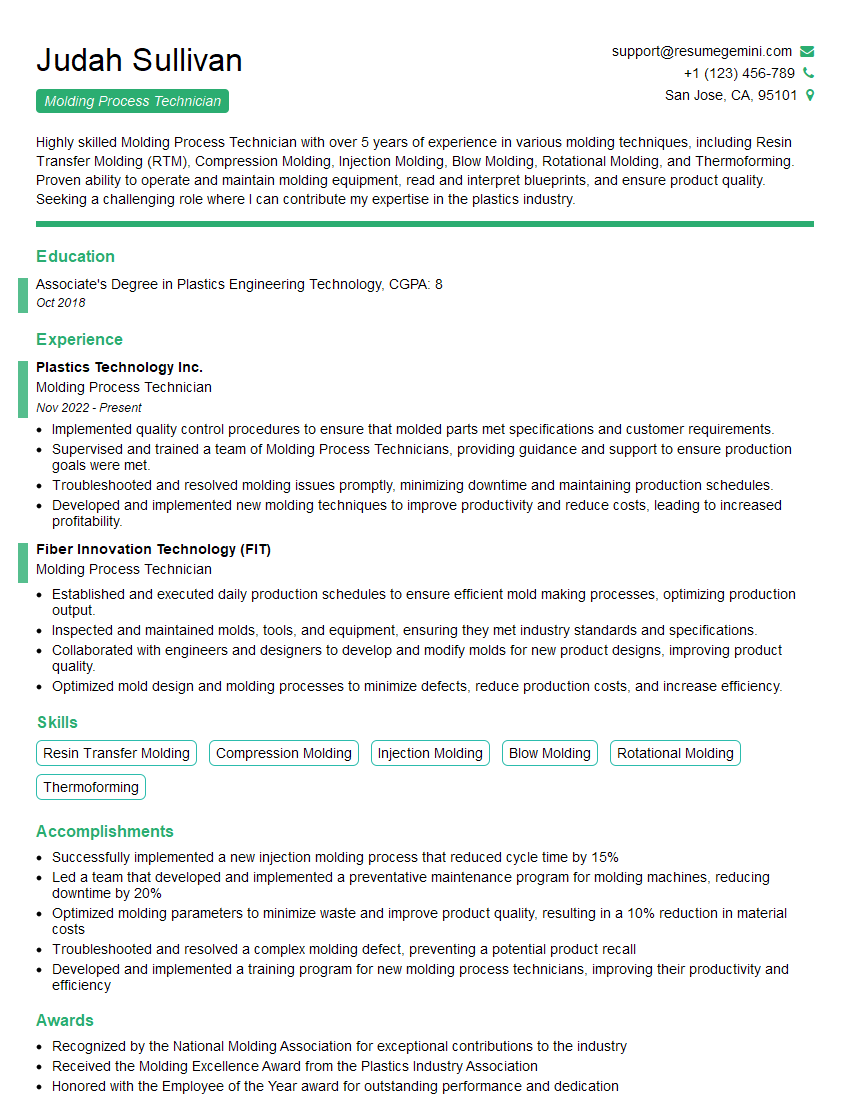

Judah Sullivan

Molding Process Technician

Summary

Highly skilled Molding Process Technician with over 5 years of experience in various molding techniques, including Resin Transfer Molding (RTM), Compression Molding, Injection Molding, Blow Molding, Rotational Molding, and Thermoforming. Proven ability to operate and maintain molding equipment, read and interpret blueprints, and ensure product quality. Seeking a challenging role where I can contribute my expertise in the plastics industry.

Education

Associate’s Degree in Plastics Engineering Technology

October 2018

Skills

- Resin Transfer Molding

- Compression Molding

- Injection Molding

- Blow Molding

- Rotational Molding

- Thermoforming

Work Experience

Molding Process Technician

- Implemented quality control procedures to ensure that molded parts met specifications and customer requirements.

- Supervised and trained a team of Molding Process Technicians, providing guidance and support to ensure production goals were met.

- Troubleshooted and resolved molding issues promptly, minimizing downtime and maintaining production schedules.

- Developed and implemented new molding techniques to improve productivity and reduce costs, leading to increased profitability.

Molding Process Technician

- Established and executed daily production schedules to ensure efficient mold making processes, optimizing production output.

- Inspected and maintained molds, tools, and equipment, ensuring they met industry standards and specifications.

- Collaborated with engineers and designers to develop and modify molds for new product designs, improving product quality.

- Optimized mold design and molding processes to minimize defects, reduce production costs, and increase efficiency.

Accomplishments

- Successfully implemented a new injection molding process that reduced cycle time by 15%

- Led a team that developed and implemented a preventative maintenance program for molding machines, reducing downtime by 20%

- Optimized molding parameters to minimize waste and improve product quality, resulting in a 10% reduction in material costs

- Troubleshooted and resolved a complex molding defect, preventing a potential product recall

- Developed and implemented a training program for new molding process technicians, improving their productivity and efficiency

Awards

- Recognized by the National Molding Association for exceptional contributions to the industry

- Received the Molding Excellence Award from the Plastics Industry Association

- Honored with the Employee of the Year award for outstanding performance and dedication

- Recognized for achieving the highest production output among all molding process technicians in the department

Certificates

- Certified Molding Technician (CMT)

- Certified Molding Engineer (CME)

- Certified Plastics Engineer (CPE)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molding Process Technician

- Highlight your technical skills and experience in various molding techniques.

- Emphasize your ability to operate and maintain molding equipment efficiently.

- Showcase your problem-solving skills and ability to troubleshoot and resolve molding issues.

- Demonstrate your commitment to quality control and safety by mentioning your experience in inspecting and testing molded products.

Essential Experience Highlights for a Strong Molding Process Technician Resume

- Setup and operate molding machines, including preparing molds, loading materials, and setting process parameters.

- Monitor and control molding processes to ensure product quality and efficiency.

- Troubleshoot and resolve molding problems, such as defective parts, mold contamination, and equipment malfunctions.

- Maintain and clean molding equipment to ensure optimal performance and safety.

- Inspect and test molded products to verify dimensional accuracy, surface finish, and other quality specifications.

- Adhere to safety protocols and maintain a clean and organized work environment.

- Collaborate with engineers and production teams to improve molding processes and optimize productivity.

Frequently Asked Questions (FAQ’s) For Molding Process Technician

What are the different types of molding processes?

There are various molding processes, including Resin Transfer Molding (RTM), Compression Molding, Injection Molding, Blow Molding, Rotational Molding, and Thermoforming, each with its own unique characteristics and applications.

What are the key responsibilities of a Molding Process Technician?

Molding Process Technicians are responsible for setting up and operating molding machines, monitoring and controlling molding processes, troubleshooting and resolving molding problems, maintaining and cleaning molding equipment, and inspecting and testing molded products to ensure quality.

What qualifications and skills are required to become a Molding Process Technician?

Molding Process Technicians typically have an Associate’s Degree in Plastics Engineering Technology or a related field. They should also have experience and skills in various molding techniques, operating and maintaining molding equipment, troubleshooting and resolving molding problems, and inspecting and testing molded products.

What is the job outlook for Molding Process Technicians?

The job outlook for Molding Process Technicians is expected to be good in the coming years, as there is a growing demand for qualified professionals in the plastics industry.

What are the benefits of a career as a Molding Process Technician?

Molding Process Technicians can enjoy a stable career with competitive salaries and benefits. They also have the opportunity to work in a variety of industries, such as automotive, electronics, and medical.