Are you a seasoned Steel Molder seeking a new career path? Discover our professionally built Steel Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

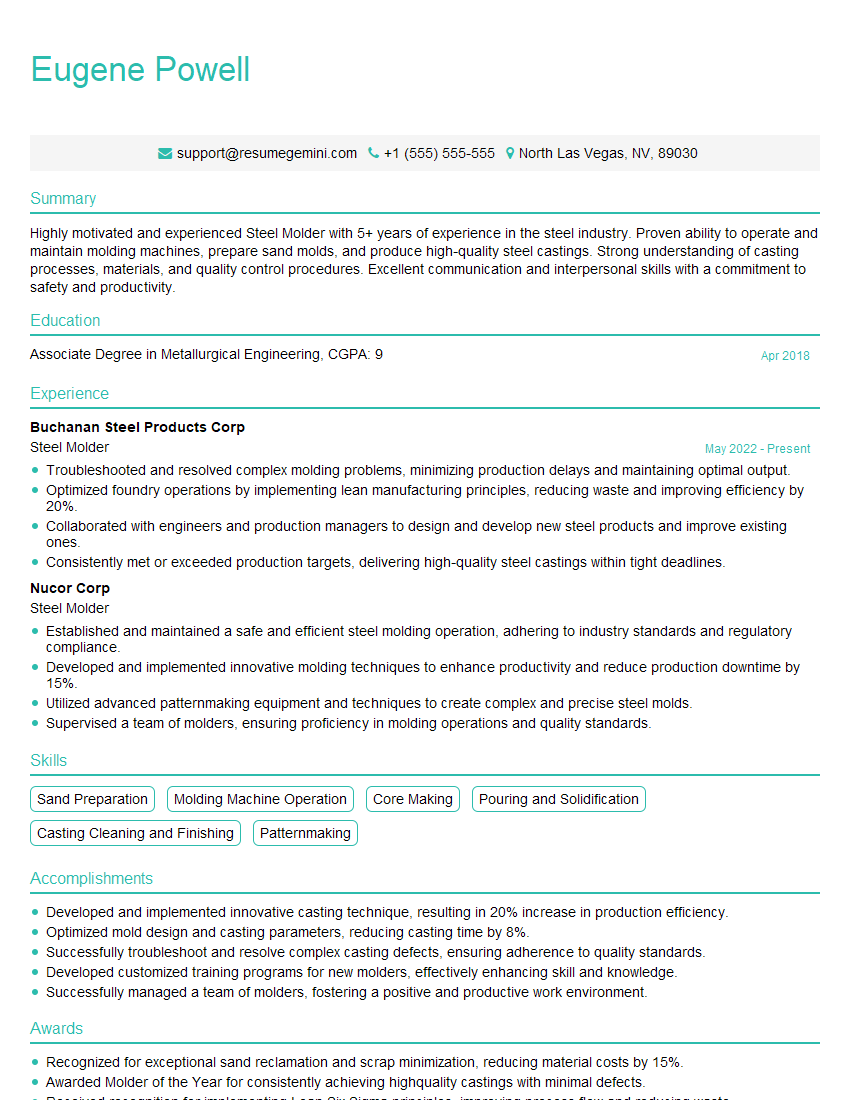

Eugene Powell

Steel Molder

Summary

Highly motivated and experienced Steel Molder with 5+ years of experience in the steel industry. Proven ability to operate and maintain molding machines, prepare sand molds, and produce high-quality steel castings. Strong understanding of casting processes, materials, and quality control procedures. Excellent communication and interpersonal skills with a commitment to safety and productivity.

Education

Associate Degree in Metallurgical Engineering

April 2018

Skills

- Sand Preparation

- Molding Machine Operation

- Core Making

- Pouring and Solidification

- Casting Cleaning and Finishing

- Patternmaking

Work Experience

Steel Molder

- Troubleshooted and resolved complex molding problems, minimizing production delays and maintaining optimal output.

- Optimized foundry operations by implementing lean manufacturing principles, reducing waste and improving efficiency by 20%.

- Collaborated with engineers and production managers to design and develop new steel products and improve existing ones.

- Consistently met or exceeded production targets, delivering high-quality steel castings within tight deadlines.

Steel Molder

- Established and maintained a safe and efficient steel molding operation, adhering to industry standards and regulatory compliance.

- Developed and implemented innovative molding techniques to enhance productivity and reduce production downtime by 15%.

- Utilized advanced patternmaking equipment and techniques to create complex and precise steel molds.

- Supervised a team of molders, ensuring proficiency in molding operations and quality standards.

Accomplishments

- Developed and implemented innovative casting technique, resulting in 20% increase in production efficiency.

- Optimized mold design and casting parameters, reducing casting time by 8%.

- Successfully troubleshoot and resolve complex casting defects, ensuring adherence to quality standards.

- Developed customized training programs for new molders, effectively enhancing skill and knowledge.

- Successfully managed a team of molders, fostering a positive and productive work environment.

Awards

- Recognized for exceptional sand reclamation and scrap minimization, reducing material costs by 15%.

- Awarded Molder of the Year for consistently achieving highquality castings with minimal defects.

- Received recognition for implementing Lean Six Sigma principles, improving process flow and reducing waste.

- Honored for exemplary safety practices, maintaining an unblemished safety record for three consecutive years.

Certificates

- Certified Steel Molder (CSM)

- OSHA 10-Hour Safety Training

- ISO 9001 Quality Management System

- American Foundry Society (AFS) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Molder

- Highlight your experience and skills in operating and maintaining molding machines.

- Quantify your accomplishments by providing specific examples of projects or tasks you have completed successfully.

- Demonstrate your knowledge of casting processes, materials, and quality control procedures.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

Essential Experience Highlights for a Strong Steel Molder Resume

- Prepare sand molds using various techniques such as jolt-squeeze, vacuum molding, and match-plate molding

- Operate molding machines to produce steel castings according to specifications

- Make and assemble cores using core making machines or hand tools

- Set up and operate pouring equipment to fill molds with molten steel

- Inspect castings for defects and perform necessary finishing operations

- Maintain and repair molding equipment to ensure optimal performance

- Follow safety procedures and regulations to maintain a safe work environment

Frequently Asked Questions (FAQ’s) For Steel Molder

What is the role of a Steel Molder?

A Steel Molder is responsible for producing steel castings by preparing sand molds, operating molding machines, making and assembling cores, pouring molten steel into molds, and inspecting and finishing castings.

What are the key skills required to be a Steel Molder?

Key skills include sand preparation, molding machine operation, core making, pouring and solidification, casting cleaning and finishing, and patternmaking.

What is the job outlook for Steel Molders?

The job outlook for Steel Molders is expected to be stable, with average growth projected over the next few years.

What is the average salary for a Steel Molder?

The average salary for a Steel Molder varies depending on experience, location, and company size, but typically ranges from $30,000 to $60,000 per year.

What are the career advancement opportunities for Steel Molders?

Career advancement opportunities for Steel Molders include promotions to supervisory or management positions, or specializing in a particular area of casting, such as mold design or quality control.

What are the working conditions like for Steel Molders?

Steel Molders typically work in foundries, which can be hot, noisy, and dirty. They may also work with heavy equipment and molten metal, so safety precautions are essential.

What are the educational requirements to become a Steel Molder?

While formal education is not always required, most Steel Molders have at least a high school diploma or equivalent. Some may also have an associate degree or certificate in a related field, such as metallurgy or manufacturing.