Are you a seasoned Machine Tool Operator seeking a new career path? Discover our professionally built Machine Tool Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

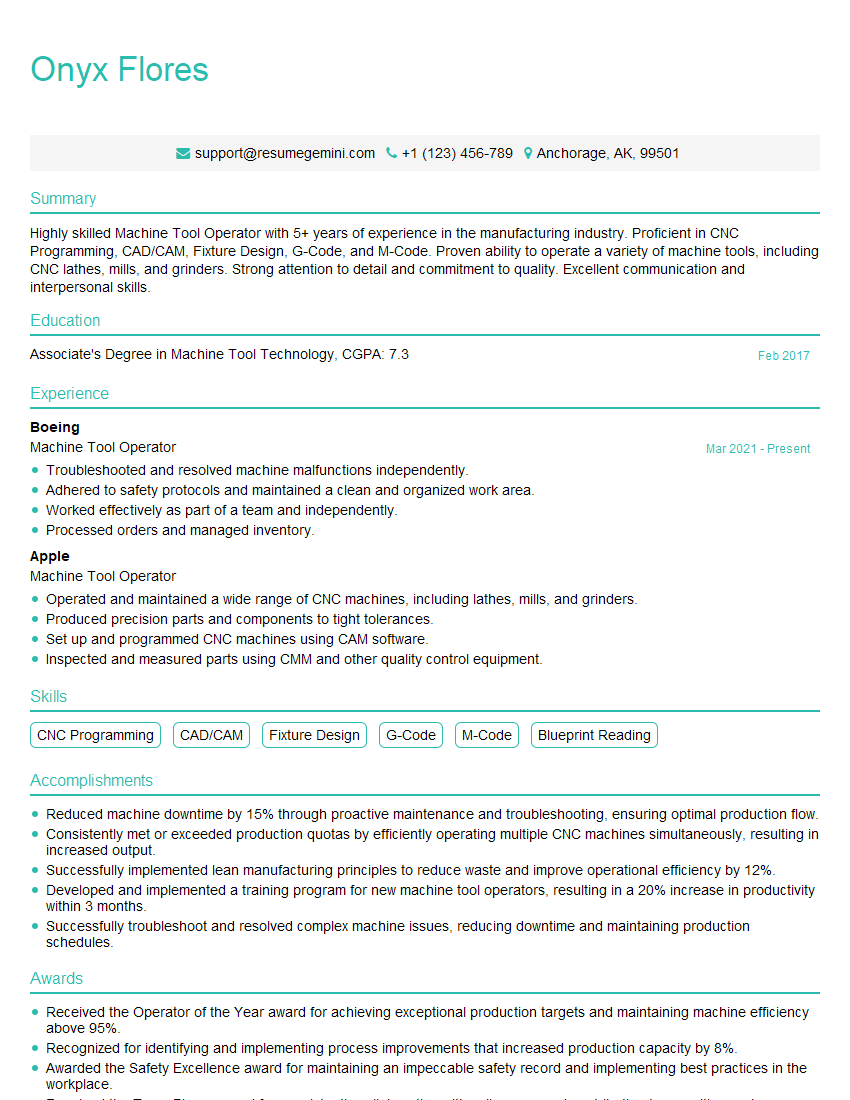

Onyx Flores

Machine Tool Operator

Summary

Highly skilled Machine Tool Operator with 5+ years of experience in the manufacturing industry. Proficient in CNC Programming, CAD/CAM, Fixture Design, G-Code, and M-Code. Proven ability to operate a variety of machine tools, including CNC lathes, mills, and grinders. Strong attention to detail and commitment to quality. Excellent communication and interpersonal skills.

Education

Associate’s Degree in Machine Tool Technology

February 2017

Skills

- CNC Programming

- CAD/CAM

- Fixture Design

- G-Code

- M-Code

- Blueprint Reading

Work Experience

Machine Tool Operator

- Troubleshooted and resolved machine malfunctions independently.

- Adhered to safety protocols and maintained a clean and organized work area.

- Worked effectively as part of a team and independently.

- Processed orders and managed inventory.

Machine Tool Operator

- Operated and maintained a wide range of CNC machines, including lathes, mills, and grinders.

- Produced precision parts and components to tight tolerances.

- Set up and programmed CNC machines using CAM software.

- Inspected and measured parts using CMM and other quality control equipment.

Accomplishments

- Reduced machine downtime by 15% through proactive maintenance and troubleshooting, ensuring optimal production flow.

- Consistently met or exceeded production quotas by efficiently operating multiple CNC machines simultaneously, resulting in increased output.

- Successfully implemented lean manufacturing principles to reduce waste and improve operational efficiency by 12%.

- Developed and implemented a training program for new machine tool operators, resulting in a 20% increase in productivity within 3 months.

- Successfully troubleshoot and resolved complex machine issues, reducing downtime and maintaining production schedules.

Awards

- Received the Operator of the Year award for achieving exceptional production targets and maintaining machine efficiency above 95%.

- Recognized for identifying and implementing process improvements that increased production capacity by 8%.

- Awarded the Safety Excellence award for maintaining an impeccable safety record and implementing best practices in the workplace.

- Received the Team Player award for consistently collaborating with colleagues and contributing to a positive work environment.

Certificates

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

- Mastercam Certification

- SolidWorks Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Tool Operator

- Highlight your skills and experience in CNC Programming, CAD/CAM, and Fixture Design.

- Showcase your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Machine Tool Operator Resume

- Operate and maintain a variety of machine tools, including CNC lathes, mills, and grinders.

- Interpret blueprints and technical drawings to determine machining parameters.

- Write and modify CNC programs to control machine tools.

- Set up and adjust fixtures and tooling to ensure precision machining.

- Inspect machined parts to ensure they meet specifications.

- Troubleshoot and resolve machine malfunctions.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Machine Tool Operator

What are the key skills for a Machine Tool Operator?

The key skills for a Machine Tool Operator include CNC Programming, CAD/CAM, Fixture Design, G-Code, M-Code, and Blueprint Reading.

What is the work environment like for a Machine Tool Operator?

Machine Tool Operators typically work in manufacturing facilities, where they operate machine tools to create parts for various products.

What is the career outlook for Machine Tool Operators?

The career outlook for Machine Tool Operators is expected to be good, with a projected growth of 4% from 2019 to 2029.

What are the salary expectations for Machine Tool Operators?

The salary expectations for Machine Tool Operators vary depending on experience, skills, and location. According to Glassdoor, the average salary for Machine Tool Operators in the United States is around $25,000 per year.

What are the educational requirements for Machine Tool Operators?

Most Machine Tool Operators have a high school diploma or equivalent. However, some employers may prefer candidates with an Associate’s Degree in Machine Tool Technology.

What are the personal qualities of a successful Machine Tool Operator?

Successful Machine Tool Operators typically have strong attention to detail, manual dexterity, and problem-solving skills.

What are the certifications available for Machine Tool Operators?

There are several certifications available for Machine Tool Operators, including the Certified Machine Tool Operator (CMTO) certification from the National Institute for Metalworking Skills (NIMS).

What are the professional organizations for Machine Tool Operators?

There are several professional organizations for Machine Tool Operators, including the National Tooling and Machining Association (NTMA) and the American Society of Manufacturing Engineers (ASME).