Are you a seasoned Tool Operator seeking a new career path? Discover our professionally built Tool Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

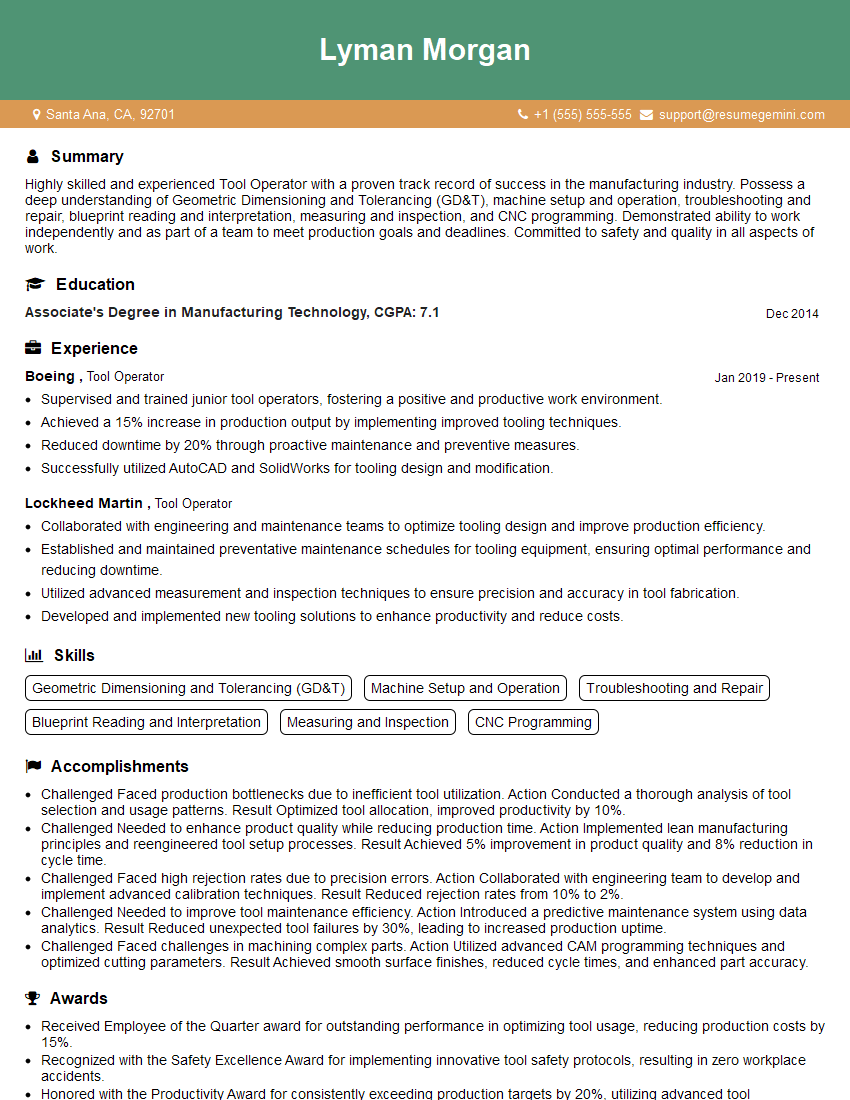

Lyman Morgan

Tool Operator

Summary

Highly skilled and experienced Tool Operator with a proven track record of success in the manufacturing industry. Possess a deep understanding of Geometric Dimensioning and Tolerancing (GD&T), machine setup and operation, troubleshooting and repair, blueprint reading and interpretation, measuring and inspection, and CNC programming. Demonstrated ability to work independently and as part of a team to meet production goals and deadlines. Committed to safety and quality in all aspects of work.

Education

Associate’s Degree in Manufacturing Technology

December 2014

Skills

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Setup and Operation

- Troubleshooting and Repair

- Blueprint Reading and Interpretation

- Measuring and Inspection

- CNC Programming

Work Experience

Tool Operator

- Supervised and trained junior tool operators, fostering a positive and productive work environment.

- Achieved a 15% increase in production output by implementing improved tooling techniques.

- Reduced downtime by 20% through proactive maintenance and preventive measures.

- Successfully utilized AutoCAD and SolidWorks for tooling design and modification.

Tool Operator

- Collaborated with engineering and maintenance teams to optimize tooling design and improve production efficiency.

- Established and maintained preventative maintenance schedules for tooling equipment, ensuring optimal performance and reducing downtime.

- Utilized advanced measurement and inspection techniques to ensure precision and accuracy in tool fabrication.

- Developed and implemented new tooling solutions to enhance productivity and reduce costs.

Accomplishments

- Challenged Faced production bottlenecks due to inefficient tool utilization. Action Conducted a thorough analysis of tool selection and usage patterns. Result Optimized tool allocation, improved productivity by 10%.

- Challenged Needed to enhance product quality while reducing production time. Action Implemented lean manufacturing principles and reengineered tool setup processes. Result Achieved 5% improvement in product quality and 8% reduction in cycle time.

- Challenged Faced high rejection rates due to precision errors. Action Collaborated with engineering team to develop and implement advanced calibration techniques. Result Reduced rejection rates from 10% to 2%.

- Challenged Needed to improve tool maintenance efficiency. Action Introduced a predictive maintenance system using data analytics. Result Reduced unexpected tool failures by 30%, leading to increased production uptime.

- Challenged Faced challenges in machining complex parts. Action Utilized advanced CAM programming techniques and optimized cutting parameters. Result Achieved smooth surface finishes, reduced cycle times, and enhanced part accuracy.

Awards

- Received Employee of the Quarter award for outstanding performance in optimizing tool usage, reducing production costs by 15%.

- Recognized with the Safety Excellence Award for implementing innovative tool safety protocols, resulting in zero workplace accidents.

- Honored with the Productivity Award for consistently exceeding production targets by 20%, utilizing advanced tool techniques.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Tooling Engineer (CTE)

- Certified Quality Engineer (CQE)

- Certified Production Technician (CPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Operator

- Highlight your skills and experience in GD&T, machine setup and operation, and troubleshooting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Proofread your resume carefully for any errors in grammar or spelling.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Tool Operator Resume

- Operate and maintain a variety of machine tools, including CNC machines, lathes, mills, and grinders.

- Interpret blueprints and technical drawings to determine production requirements.

- Set up and adjust machines according to specifications, ensuring accuracy and precision.

- Troubleshoot and repair machine malfunctions, minimizing downtime and maximizing productivity.

- Inspect finished parts to ensure they meet quality standards.

- Maintain a clean and organized work area, adhering to safety regulations and procedures.

Frequently Asked Questions (FAQ’s) For Tool Operator

What are the key skills required to be a Tool Operator?

Key skills required for a Tool Operator include Geometric Dimensioning and Tolerancing (GD&T), machine setup and operation, troubleshooting and repair, blueprint reading and interpretation, measuring and inspection, and CNC programming.

What are the typical job duties of a Tool Operator?

Typical job duties of a Tool Operator include operating and maintaining machine tools, interpreting blueprints and technical drawings, setting up and adjusting machines, troubleshooting and repairing machine malfunctions, inspecting finished parts, and maintaining a clean and organized work area.

What education and training are required to become a Tool Operator?

Most Tool Operators have an associate’s degree in manufacturing technology or a related field.

What are the career prospects for Tool Operators?

Tool Operators can advance to positions such as CNC programmer, manufacturing engineer, or quality control inspector.

What is the average salary for a Tool Operator?

The average salary for a Tool Operator is around $40,000 per year.

What are the benefits of working as a Tool Operator?

Benefits of working as a Tool Operator include job security, opportunities for advancement, and a competitive salary.