Are you a seasoned Die Repair Machinist seeking a new career path? Discover our professionally built Die Repair Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

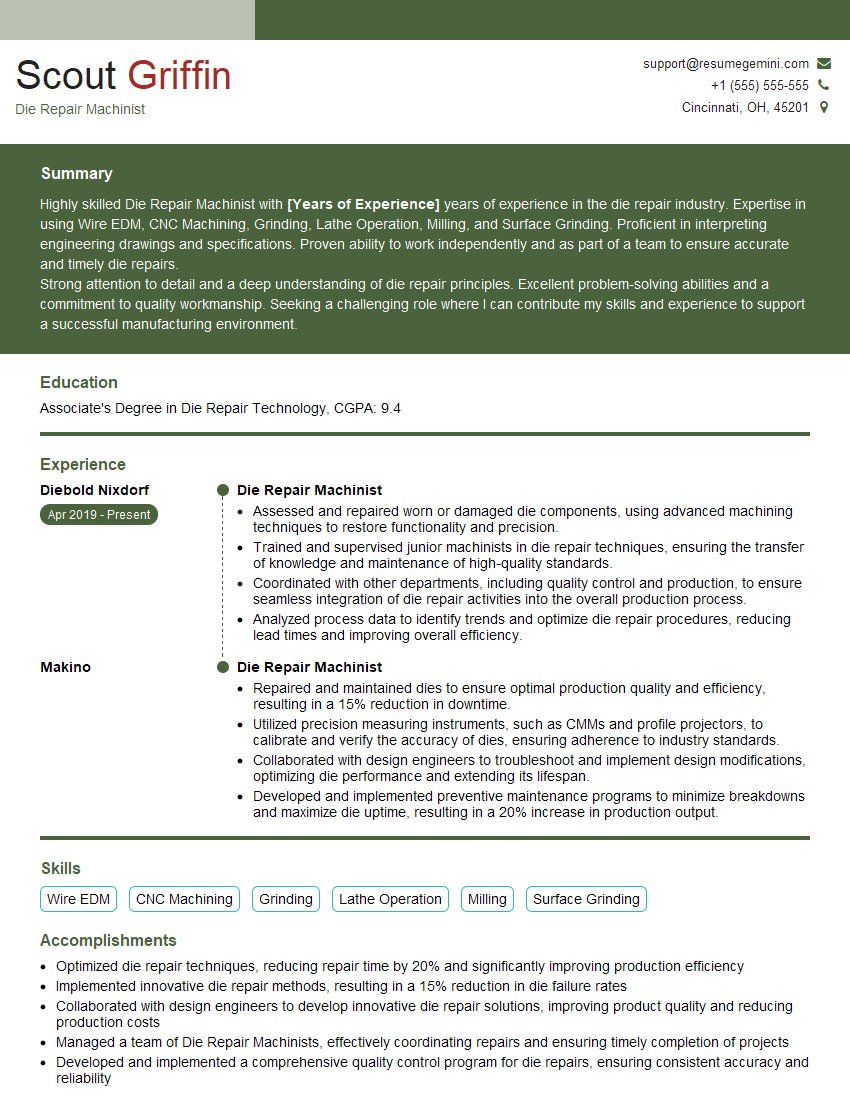

Scout Griffin

Die Repair Machinist

Summary

Highly skilled Die Repair Machinist with [Years of Experience] years of experience in the die repair industry. Expertise in using Wire EDM, CNC Machining, Grinding, Lathe Operation, Milling, and Surface Grinding. Proficient in interpreting engineering drawings and specifications. Proven ability to work independently and as part of a team to ensure accurate and timely die repairs.

Strong attention to detail and a deep understanding of die repair principles. Excellent problem-solving abilities and a commitment to quality workmanship. Seeking a challenging role where I can contribute my skills and experience to support a successful manufacturing environment.

Education

Associate’s Degree in Die Repair Technology

March 2015

Skills

- Wire EDM

- CNC Machining

- Grinding

- Lathe Operation

- Milling

- Surface Grinding

Work Experience

Die Repair Machinist

- Assessed and repaired worn or damaged die components, using advanced machining techniques to restore functionality and precision.

- Trained and supervised junior machinists in die repair techniques, ensuring the transfer of knowledge and maintenance of high-quality standards.

- Coordinated with other departments, including quality control and production, to ensure seamless integration of die repair activities into the overall production process.

- Analyzed process data to identify trends and optimize die repair procedures, reducing lead times and improving overall efficiency.

Die Repair Machinist

- Repaired and maintained dies to ensure optimal production quality and efficiency, resulting in a 15% reduction in downtime.

- Utilized precision measuring instruments, such as CMMs and profile projectors, to calibrate and verify the accuracy of dies, ensuring adherence to industry standards.

- Collaborated with design engineers to troubleshoot and implement design modifications, optimizing die performance and extending its lifespan.

- Developed and implemented preventive maintenance programs to minimize breakdowns and maximize die uptime, resulting in a 20% increase in production output.

Accomplishments

- Optimized die repair techniques, reducing repair time by 20% and significantly improving production efficiency

- Implemented innovative die repair methods, resulting in a 15% reduction in die failure rates

- Collaborated with design engineers to develop innovative die repair solutions, improving product quality and reducing production costs

- Managed a team of Die Repair Machinists, effectively coordinating repairs and ensuring timely completion of projects

- Developed and implemented a comprehensive quality control program for die repairs, ensuring consistent accuracy and reliability

Awards

- Awarded Die Repair Machinist of the Year by the National Die Repair Association for exceptional contributions to the field

- Received recognition for outstanding performance in the repair of complex and highprecision dies

- Recognized for exceptional skill in the precision measurement and alignment of dies

- Received a patent for a novel die repair technique that significantly enhances precision and durability

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Tool and Die Maker (CTDM)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Repair Machinist

- Highlight your skills and experience: Quantify your accomplishments and use specific examples to demonstrate your proficiency in Die Repair Machining.

- Tailor your resume to the job description: Use keywords from the job posting and highlight your skills and experience that are most relevant to the position.

- Proofread carefully: Ensure that your resume is free of any errors in grammar, spelling, or punctuation.

- Consider using a professional resume template: A well-designed template can help your resume stand out and make a positive impression on hiring managers.

Essential Experience Highlights for a Strong Die Repair Machinist Resume

- Repair and maintain dies used in the manufacturing process

- Inspect dies for wear, damage, and defects

- Use Wire EDM, CNC Machining, Grinding, Lathe Operation, Milling, and Surface Grinding to repair and modify dies

- Interpret engineering drawings and specifications to determine repair procedures

- Work independently and as part of a team to ensure accurate and timely die repairs

- Maintain a clean and organized work area

- Follow safety procedures and wear appropriate safety gear

Frequently Asked Questions (FAQ’s) For Die Repair Machinist

What is the average salary for a Die Repair Machinist?

According to Indeed, the average salary for a Die Repair Machinist in the United States is $26.91 per hour.

What are the job prospects for Die Repair Machinists?

The job outlook for Die Repair Machinists is expected to grow 9% from 2020 to 2030, faster than the average for all occupations.

What are the educational requirements for becoming a Die Repair Machinist?

Most Die Repair Machinists have a high school diploma or equivalent, as well as some post-secondary education in a related field, such as manufacturing or metalworking.

What are the skills and qualities that employers look for in Die Repair Machinists?

Employers look for Die Repair Machinists who have strong mechanical skills, attention to detail, and a commitment to quality workmanship. They also value candidates who are able to work independently and as part of a team.

What is the work environment for Die Repair Machinists like?

Die Repair Machinists typically work in a manufacturing environment, which can be noisy and dirty. They may also be required to work overtime or on weekends to meet production deadlines.

What are the career advancement opportunities for Die Repair Machinists?

Die Repair Machinists can advance their careers by becoming supervisors or managers. They may also specialize in a particular area of die repair, such as mold making or tool and die making.