Are you a seasoned Tool and Die Maker Level Five seeking a new career path? Discover our professionally built Tool and Die Maker Level Five Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

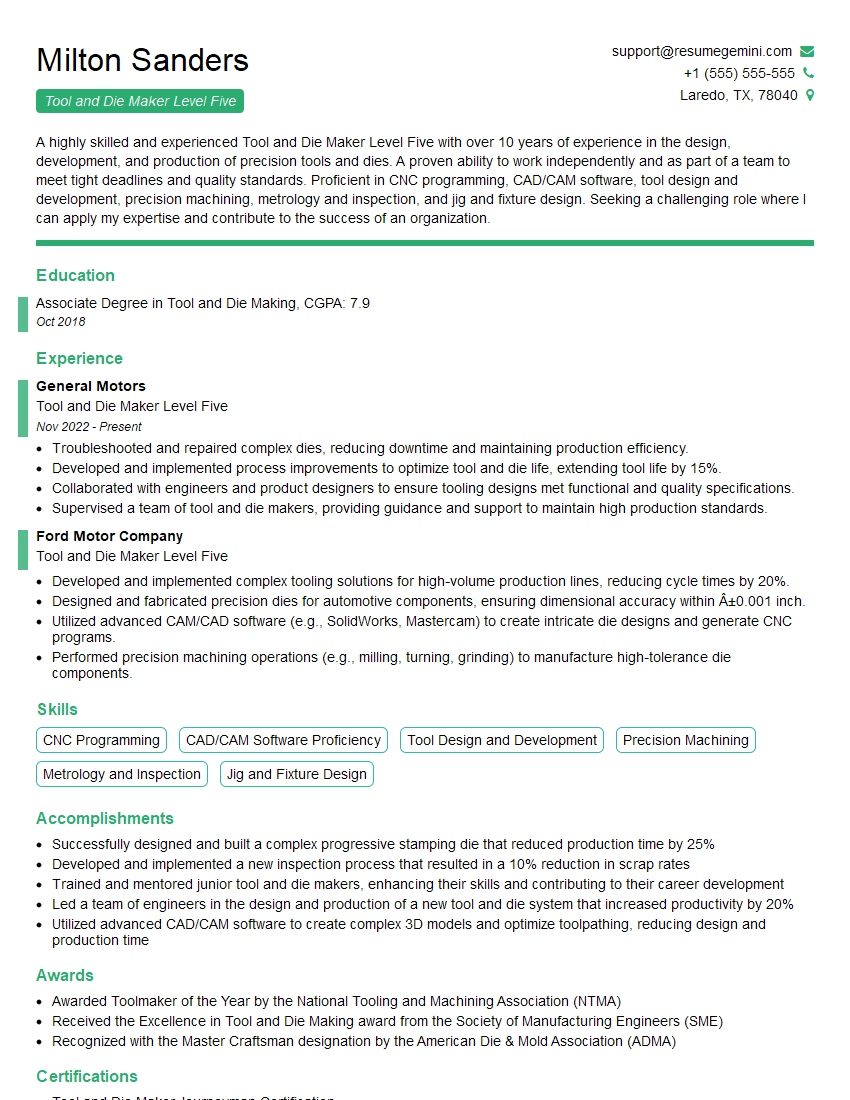

Milton Sanders

Tool and Die Maker Level Five

Summary

A highly skilled and experienced Tool and Die Maker Level Five with over 10 years of experience in the design, development, and production of precision tools and dies. A proven ability to work independently and as part of a team to meet tight deadlines and quality standards. Proficient in CNC programming, CAD/CAM software, tool design and development, precision machining, metrology and inspection, and jig and fixture design. Seeking a challenging role where I can apply my expertise and contribute to the success of an organization.

Education

Associate Degree in Tool and Die Making

October 2018

Skills

- CNC Programming

- CAD/CAM Software Proficiency

- Tool Design and Development

- Precision Machining

- Metrology and Inspection

- Jig and Fixture Design

Work Experience

Tool and Die Maker Level Five

- Troubleshooted and repaired complex dies, reducing downtime and maintaining production efficiency.

- Developed and implemented process improvements to optimize tool and die life, extending tool life by 15%.

- Collaborated with engineers and product designers to ensure tooling designs met functional and quality specifications.

- Supervised a team of tool and die makers, providing guidance and support to maintain high production standards.

Tool and Die Maker Level Five

- Developed and implemented complex tooling solutions for high-volume production lines, reducing cycle times by 20%.

- Designed and fabricated precision dies for automotive components, ensuring dimensional accuracy within ±0.001 inch.

- Utilized advanced CAM/CAD software (e.g., SolidWorks, Mastercam) to create intricate die designs and generate CNC programs.

- Performed precision machining operations (e.g., milling, turning, grinding) to manufacture high-tolerance die components.

Accomplishments

- Successfully designed and built a complex progressive stamping die that reduced production time by 25%

- Developed and implemented a new inspection process that resulted in a 10% reduction in scrap rates

- Trained and mentored junior tool and die makers, enhancing their skills and contributing to their career development

- Led a team of engineers in the design and production of a new tool and die system that increased productivity by 20%

- Utilized advanced CAD/CAM software to create complex 3D models and optimize toolpathing, reducing design and production time

Awards

- Awarded Toolmaker of the Year by the National Tooling and Machining Association (NTMA)

- Received the Excellence in Tool and Die Making award from the Society of Manufacturing Engineers (SME)

- Recognized with the Master Craftsman designation by the American Die & Mold Association (ADMA)

Certificates

- Tool and Die Maker Journeyman Certification

- CNC Machinist Certification

- ISO 9001:2015 Quality Management System Certification

- Lean Six Sigma Yellow Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool and Die Maker Level Five

- Highlight your skills and experience. Be sure to list all of your relevant skills and experience in your resume. This will help potential employers see why you’re qualified for the job.

- Use specific examples. When describing your experience, be sure to use specific examples that demonstrate your skills and abilities. This will help potential employers see what you’re capable of.

- Tailor your resume to the job. Be sure to tailor your resume to each job you apply for. This means highlighting the skills and experience that are most relevant to the job.

- Proofread your resume carefully. Before you submit your resume, be sure to proofread it carefully for any errors. This will help you make a good impression on potential employers

Essential Experience Highlights for a Strong Tool and Die Maker Level Five Resume

- Design and develop tools, dies, and fixtures using CAD/CAM software

- Program and operate CNC machines to produce precision parts and components

- Inspect and test tools and dies to ensure they meet specifications

- Maintain and repair tools, dies, and fixtures

- Work with engineers and other team members to develop and implement new processes and procedures

- Provide training and support to other tool and die makers

Frequently Asked Questions (FAQ’s) For Tool and Die Maker Level Five

What is a tool and die maker?

A tool and die maker is a skilled worker who designs and builds tools, dies, and fixtures used in the manufacturing process.

What are the different types of tools and dies?

There are many different types of tools and dies, but the most common are stamping dies, forming dies, and cutting dies.

What are the different types of materials used in tool and die making?

The most common materials used in tool and die making are steel, aluminum, and plastic.

What are the different processes used in tool and die making?

The most common processes used in tool and die making are machining, grinding, and heat treating.

What are the different career paths for tool and die makers?

Tool and die makers can work in a variety of industries, including automotive, aerospace, and medical. They can also start their own businesses.

What are the benefits of working as a tool and die maker?

Tool and die makers enjoy a number of benefits, including good pay, job security, and the opportunity to work with their hands.

What are the challenges of working as a tool and die maker?

Tool and die makers can face a number of challenges, including working with sharp tools and dangerous machinery, and working in a noisy environment.

What are the most important skills for a tool and die maker?

The most important skills for a tool and die maker are precision machining, blueprint reading, and problem solving.