Are you a seasoned Toolmaker seeking a new career path? Discover our professionally built Toolmaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

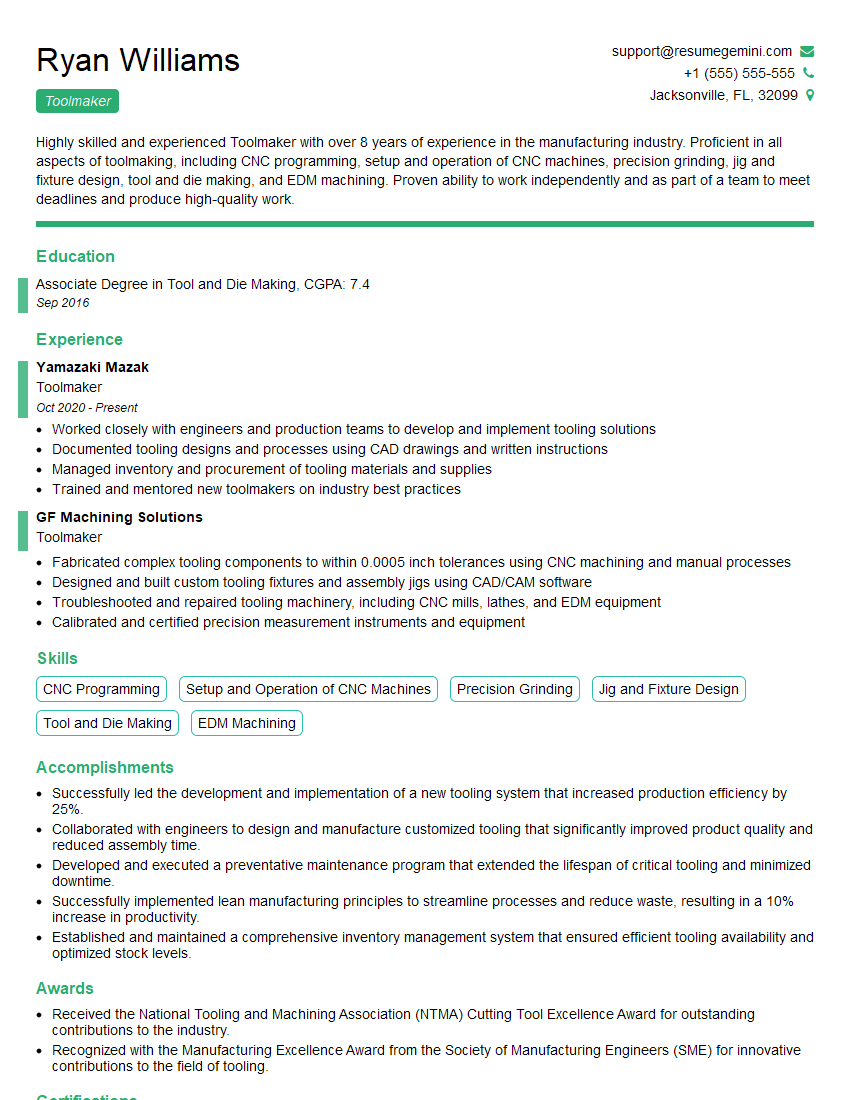

Ryan Williams

Toolmaker

Summary

Highly skilled and experienced Toolmaker with over 8 years of experience in the manufacturing industry. Proficient in all aspects of toolmaking, including CNC programming, setup and operation of CNC machines, precision grinding, jig and fixture design, tool and die making, and EDM machining. Proven ability to work independently and as part of a team to meet deadlines and produce high-quality work.

Education

Associate Degree in Tool and Die Making

September 2016

Skills

- CNC Programming

- Setup and Operation of CNC Machines

- Precision Grinding

- Jig and Fixture Design

- Tool and Die Making

- EDM Machining

Work Experience

Toolmaker

- Worked closely with engineers and production teams to develop and implement tooling solutions

- Documented tooling designs and processes using CAD drawings and written instructions

- Managed inventory and procurement of tooling materials and supplies

- Trained and mentored new toolmakers on industry best practices

Toolmaker

- Fabricated complex tooling components to within 0.0005 inch tolerances using CNC machining and manual processes

- Designed and built custom tooling fixtures and assembly jigs using CAD/CAM software

- Troubleshooted and repaired tooling machinery, including CNC mills, lathes, and EDM equipment

- Calibrated and certified precision measurement instruments and equipment

Accomplishments

- Successfully led the development and implementation of a new tooling system that increased production efficiency by 25%.

- Collaborated with engineers to design and manufacture customized tooling that significantly improved product quality and reduced assembly time.

- Developed and executed a preventative maintenance program that extended the lifespan of critical tooling and minimized downtime.

- Successfully implemented lean manufacturing principles to streamline processes and reduce waste, resulting in a 10% increase in productivity.

- Established and maintained a comprehensive inventory management system that ensured efficient tooling availability and optimized stock levels.

Awards

- Received the National Tooling and Machining Association (NTMA) Cutting Tool Excellence Award for outstanding contributions to the industry.

- Recognized with the Manufacturing Excellence Award from the Society of Manufacturing Engineers (SME) for innovative contributions to the field of tooling.

Certificates

- Certified Toolmaker (CTM)

- CNC Programming Certification

- EDM Machining Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Toolmaker

- Highlight your skills and experience in CNC programming and operation.

- Quantify your accomplishments whenever possible.

- Use keywords throughout your resume to make it searchable.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Toolmaker Resume

- Program and operate CNC machines to produce precision parts and components.

- Set up and maintain CNC machines to ensure optimal performance.

- Grind and finish tools and dies to meet precise specifications.

- Design and build jigs and fixtures to hold and position workpieces during machining.

- Troubleshoot and repair CNC machines and tooling.

- Maintain a clean and organized work area.

- Follow all safety protocols and procedures.

Frequently Asked Questions (FAQ’s) For Toolmaker

What is the job outlook for Toolmakers?

The job outlook for Toolmakers is expected to be good over the next few years. The increasing use of CNC machines and other automated equipment in manufacturing is creating a demand for skilled workers who can operate and maintain these machines.

What are the educational requirements for becoming a Toolmaker?

Most Toolmakers have an associate degree in tool and die making or a related field. Some Toolmakers also have a bachelor’s degree in engineering or a related field.

What are the typical duties of a Toolmaker?

Toolmakers typically program and operate CNC machines to produce precision parts and components. They also set up and maintain CNC machines, grind and finish tools and dies, and design and build jigs and fixtures.

What are the skills and qualities that are important for Toolmakers?

Toolmakers typically have strong math and science skills. They also have good mechanical aptitude and are able to work independently and as part of a team. Toolmakers must also be able to read and interpret blueprints and other technical drawings.

What is the average salary for Toolmakers?

The average salary for Toolmakers is $56,340 per year.

What are the career advancement opportunities for Toolmakers?

Toolmakers can advance to positions such as supervisor, manager, or engineer. They may also start their own businesses.