Are you a seasoned Toolmaker A seeking a new career path? Discover our professionally built Toolmaker A Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

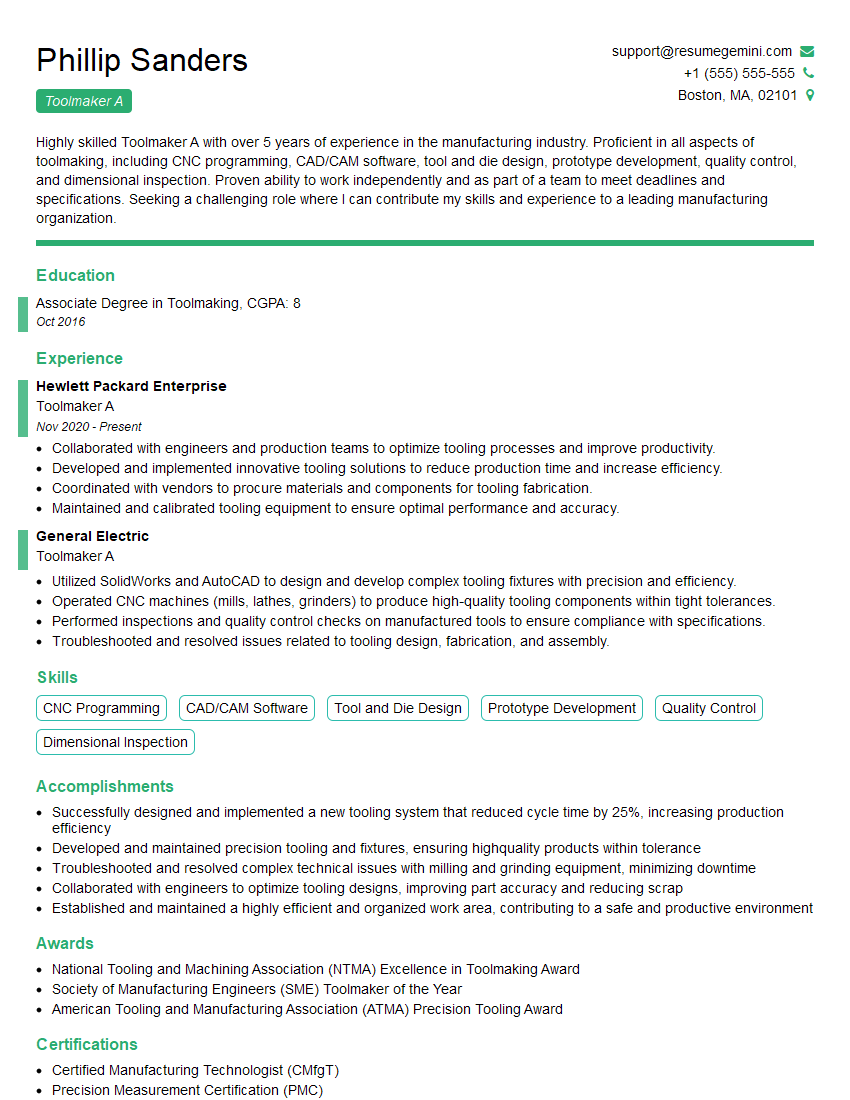

Phillip Sanders

Toolmaker A

Summary

Highly skilled Toolmaker A with over 5 years of experience in the manufacturing industry. Proficient in all aspects of toolmaking, including CNC programming, CAD/CAM software, tool and die design, prototype development, quality control, and dimensional inspection. Proven ability to work independently and as part of a team to meet deadlines and specifications. Seeking a challenging role where I can contribute my skills and experience to a leading manufacturing organization.

Education

Associate Degree in Toolmaking

October 2016

Skills

- CNC Programming

- CAD/CAM Software

- Tool and Die Design

- Prototype Development

- Quality Control

- Dimensional Inspection

Work Experience

Toolmaker A

- Collaborated with engineers and production teams to optimize tooling processes and improve productivity.

- Developed and implemented innovative tooling solutions to reduce production time and increase efficiency.

- Coordinated with vendors to procure materials and components for tooling fabrication.

- Maintained and calibrated tooling equipment to ensure optimal performance and accuracy.

Toolmaker A

- Utilized SolidWorks and AutoCAD to design and develop complex tooling fixtures with precision and efficiency.

- Operated CNC machines (mills, lathes, grinders) to produce high-quality tooling components within tight tolerances.

- Performed inspections and quality control checks on manufactured tools to ensure compliance with specifications.

- Troubleshooted and resolved issues related to tooling design, fabrication, and assembly.

Accomplishments

- Successfully designed and implemented a new tooling system that reduced cycle time by 25%, increasing production efficiency

- Developed and maintained precision tooling and fixtures, ensuring highquality products within tolerance

- Troubleshooted and resolved complex technical issues with milling and grinding equipment, minimizing downtime

- Collaborated with engineers to optimize tooling designs, improving part accuracy and reducing scrap

- Established and maintained a highly efficient and organized work area, contributing to a safe and productive environment

Awards

- National Tooling and Machining Association (NTMA) Excellence in Toolmaking Award

- Society of Manufacturing Engineers (SME) Toolmaker of the Year

- American Tooling and Manufacturing Association (ATMA) Precision Tooling Award

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Precision Measurement Certification (PMC)

- Lean Manufacturing Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Toolmaker A

- Highlight your experience and skills in your resume.

- Use specific examples to demonstrate your accomplishments.

- Tailor your resume to each job you apply for.

- Proofread your resume carefully for errors.

- Get feedback on your resume from a career counselor or other qualified professional,

Essential Experience Highlights for a Strong Toolmaker A Resume

- Program and operate CNC machines to manufacture tools, dies, fixtures, and other precision components.

- Develop and implement process plans for the manufacturing of tools and dies.

- Conduct quality control inspections on manufactured components.

- Maintain and calibrate tooling and equipment.

- Troubleshoot and resolve production issues.

- Work with engineers and designers to develop and implement new tool designs.

Frequently Asked Questions (FAQ’s) For Toolmaker A

What is a Toolmaker A?

A Toolmaker A is a skilled worker who manufactures and repairs tools, dies, and fixtures used in the production of a wide variety of products. They use a variety of machines and tools, including CNC machines, lathes, and mills, to create precision parts to meet customer specifications.

What are the responsibilities of a Toolmaker A?

Toolmakers As are responsible for a wide range of tasks, including:

What are the qualifications for a Toolmaker A?

To become a Toolmaker A, you typically need at least an associate degree in toolmaking or a related field, as well as several years of experience in a manufacturing environment.

What is the job outlook for Toolmaker As?

The job outlook for Toolmaker As is expected to be good over the next few years. This is due to the increasing demand for precision parts in a variety of industries.

What is the salary range for Toolmaker As?

The salary range for Toolmaker As varies depending on experience, location, and employer. However, the median annual salary for Toolmaker As is around $55,000.

What are the benefits of working as a Toolmaker A?

There are a number of benefits to working as a Toolmaker A, including: