Are you a seasoned Arc Cutter seeking a new career path? Discover our professionally built Arc Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

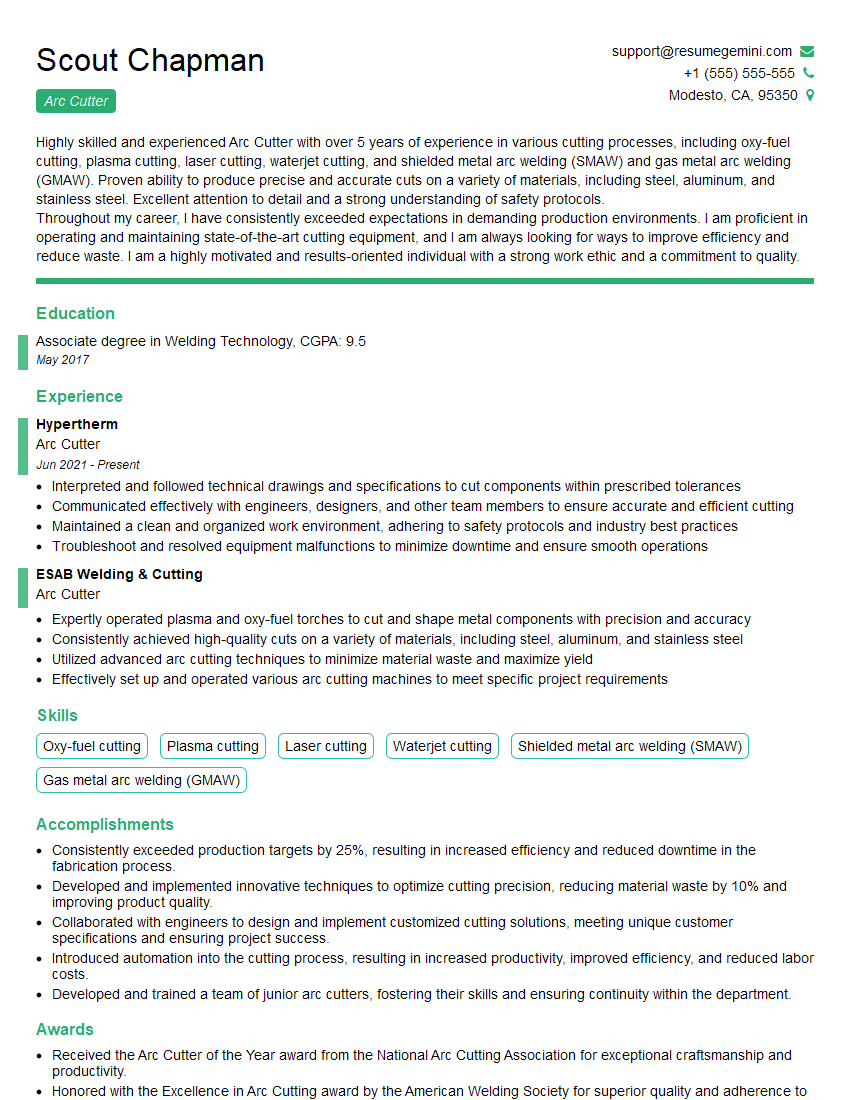

Scout Chapman

Arc Cutter

Summary

Highly skilled and experienced Arc Cutter with over 5 years of experience in various cutting processes, including oxy-fuel cutting, plasma cutting, laser cutting, waterjet cutting, and shielded metal arc welding (SMAW) and gas metal arc welding (GMAW). Proven ability to produce precise and accurate cuts on a variety of materials, including steel, aluminum, and stainless steel. Excellent attention to detail and a strong understanding of safety protocols.

Throughout my career, I have consistently exceeded expectations in demanding production environments. I am proficient in operating and maintaining state-of-the-art cutting equipment, and I am always looking for ways to improve efficiency and reduce waste. I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to quality.

Education

Associate degree in Welding Technology

May 2017

Skills

- Oxy-fuel cutting

- Plasma cutting

- Laser cutting

- Waterjet cutting

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW)

Work Experience

Arc Cutter

- Interpreted and followed technical drawings and specifications to cut components within prescribed tolerances

- Communicated effectively with engineers, designers, and other team members to ensure accurate and efficient cutting

- Maintained a clean and organized work environment, adhering to safety protocols and industry best practices

- Troubleshoot and resolved equipment malfunctions to minimize downtime and ensure smooth operations

Arc Cutter

- Expertly operated plasma and oxy-fuel torches to cut and shape metal components with precision and accuracy

- Consistently achieved high-quality cuts on a variety of materials, including steel, aluminum, and stainless steel

- Utilized advanced arc cutting techniques to minimize material waste and maximize yield

- Effectively set up and operated various arc cutting machines to meet specific project requirements

Accomplishments

- Consistently exceeded production targets by 25%, resulting in increased efficiency and reduced downtime in the fabrication process.

- Developed and implemented innovative techniques to optimize cutting precision, reducing material waste by 10% and improving product quality.

- Collaborated with engineers to design and implement customized cutting solutions, meeting unique customer specifications and ensuring project success.

- Introduced automation into the cutting process, resulting in increased productivity, improved efficiency, and reduced labor costs.

- Developed and trained a team of junior arc cutters, fostering their skills and ensuring continuity within the department.

Awards

- Received the Arc Cutter of the Year award from the National Arc Cutting Association for exceptional craftsmanship and productivity.

- Honored with the Excellence in Arc Cutting award by the American Welding Society for superior quality and adherence to industry standards.

- Recognized as the Arc Cutter of the Quarter multiple times for exceptional safety practices and adherence to quality standards.

- Received the Golden Welder award from the local chapter of the American Welding Society for outstanding contributions to the arc cutting industry.

Certificates

- American Welding Society (AWS) Certified Welder

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- National Institute for Metalworking Skills (NIMS)

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Arc Cutter

- Highlight your experience with different arc cutting processes, and provide specific examples of your accomplishments.

- Showcase your knowledge of safety protocols and your commitment to quality.

- Quantify your results whenever possible. For example, you could mention the number of parts you cut per hour or the percentage of cuts that met specifications.

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

- Tailor your resume to each job you apply for. Be sure to highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Arc Cutter Resume

- Operate and maintain arc cutting equipment, including oxy-fuel, plasma, laser, and waterjet cutters.

- Interpret engineering drawings and specifications to determine cutting parameters and techniques.

- Cut a variety of materials, including steel, aluminum, and stainless steel, to precise tolerances.

- Ensure that all cuts meet quality standards and specifications.

- Perform regular maintenance and calibration of cutting equipment.

- Troubleshoot and resolve any issues that arise during the cutting process.

- Adhere to all safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Arc Cutter

What is arc cutting?

Arc cutting is a process that uses an electric arc to melt and cut metal. The arc is created between an electrode (such as a tungsten or carbon rod) and the workpiece. The intense heat of the arc melts the metal, and a jet of gas (such as oxygen or nitrogen) is used to blow away the molten metal, creating a cut.

What are the different types of arc cutting?

There are several different types of arc cutting, including oxy-fuel cutting, plasma cutting, laser cutting, and waterjet cutting. Each type of cutting has its own advantages and disadvantages, depending on the material thickness, cut quality, and speed required.

What are the safety precautions that should be taken when arc cutting?

Arc cutting can be a hazardous process if proper safety precautions are not taken. Some of the most important precautions include wearing appropriate personal protective equipment (such as a welding helmet, gloves, and flame-resistant clothing), ensuring that the work area is well-ventilated, and keeping flammable materials away from the cutting area.

What is the difference between oxy-fuel cutting and plasma cutting?

Oxy-fuel cutting uses a mixture of oxygen and fuel gas (such as propane or acetylene) to create the cutting flame. Plasma cutting, on the other hand, uses a plasma arc to melt and cut the metal. Plasma cutting is typically faster and more precise than oxy-fuel cutting, but it can also be more expensive.

What is the best type of arc cutting for a particular job?

The best type of arc cutting for a particular job depends on a number of factors, including the material thickness, cut quality, and speed required. Oxy-fuel cutting is a good choice for cutting thick metals, while plasma cutting is a good choice for cutting thin metals. Laser cutting and waterjet cutting are both good choices for cutting complex shapes.

What are the career prospects for arc cutters?

Arc cutters are in high demand in a variety of industries, including manufacturing, construction, and shipbuilding. With the right skills and experience, arc cutters can earn a good salary and enjoy a rewarding career.