Are you a seasoned Oxyacetylene Cutter seeking a new career path? Discover our professionally built Oxyacetylene Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

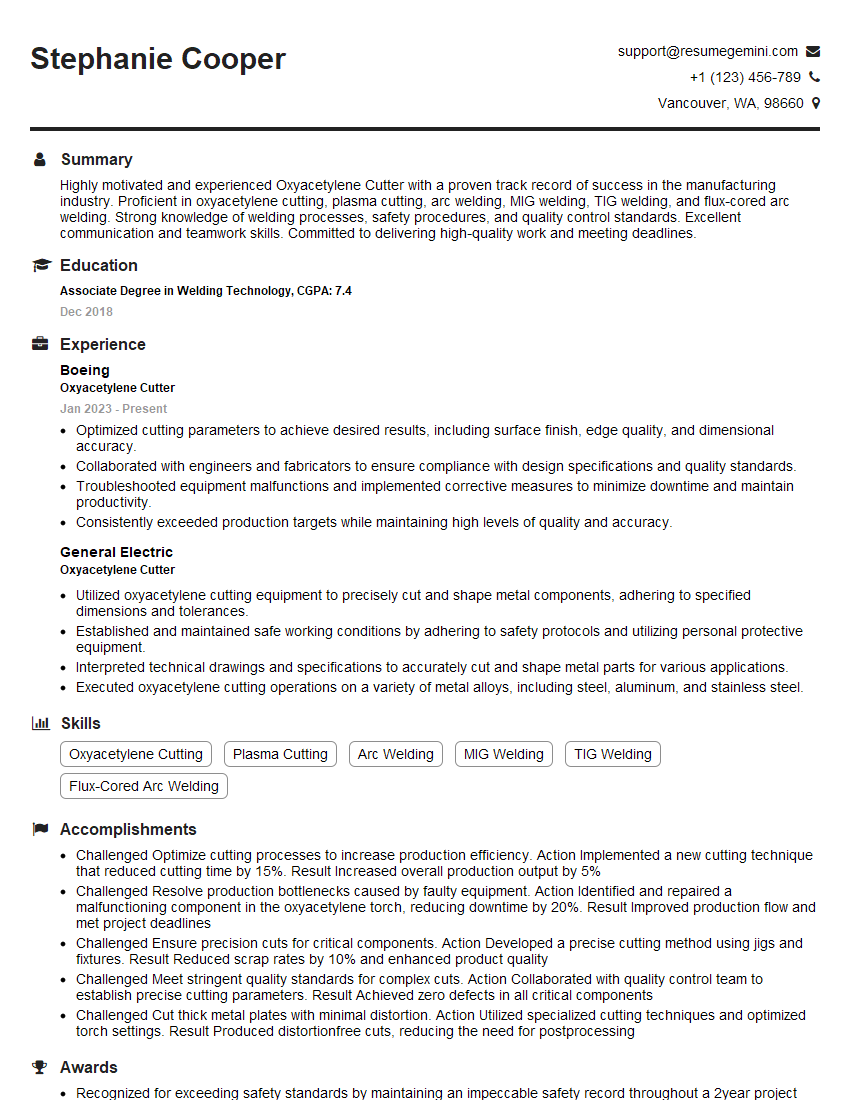

Stephanie Cooper

Oxyacetylene Cutter

Summary

Highly motivated and experienced Oxyacetylene Cutter with a proven track record of success in the manufacturing industry. Proficient in oxyacetylene cutting, plasma cutting, arc welding, MIG welding, TIG welding, and flux-cored arc welding. Strong knowledge of welding processes, safety procedures, and quality control standards. Excellent communication and teamwork skills. Committed to delivering high-quality work and meeting deadlines.

Education

Associate Degree in Welding Technology

December 2018

Skills

- Oxyacetylene Cutting

- Plasma Cutting

- Arc Welding

- MIG Welding

- TIG Welding

- Flux-Cored Arc Welding

Work Experience

Oxyacetylene Cutter

- Optimized cutting parameters to achieve desired results, including surface finish, edge quality, and dimensional accuracy.

- Collaborated with engineers and fabricators to ensure compliance with design specifications and quality standards.

- Troubleshooted equipment malfunctions and implemented corrective measures to minimize downtime and maintain productivity.

- Consistently exceeded production targets while maintaining high levels of quality and accuracy.

Oxyacetylene Cutter

- Utilized oxyacetylene cutting equipment to precisely cut and shape metal components, adhering to specified dimensions and tolerances.

- Established and maintained safe working conditions by adhering to safety protocols and utilizing personal protective equipment.

- Interpreted technical drawings and specifications to accurately cut and shape metal parts for various applications.

- Executed oxyacetylene cutting operations on a variety of metal alloys, including steel, aluminum, and stainless steel.

Accomplishments

- Challenged Optimize cutting processes to increase production efficiency. Action Implemented a new cutting technique that reduced cutting time by 15%. Result Increased overall production output by 5%

- Challenged Resolve production bottlenecks caused by faulty equipment. Action Identified and repaired a malfunctioning component in the oxyacetylene torch, reducing downtime by 20%. Result Improved production flow and met project deadlines

- Challenged Ensure precision cuts for critical components. Action Developed a precise cutting method using jigs and fixtures. Result Reduced scrap rates by 10% and enhanced product quality

- Challenged Meet stringent quality standards for complex cuts. Action Collaborated with quality control team to establish precise cutting parameters. Result Achieved zero defects in all critical components

- Challenged Cut thick metal plates with minimal distortion. Action Utilized specialized cutting techniques and optimized torch settings. Result Produced distortionfree cuts, reducing the need for postprocessing

Awards

- Recognized for exceeding safety standards by maintaining an impeccable safety record throughout a 2year project

- Awarded the Cutter of the Year award for demonstrating exceptional proficiency and efficiency in oxyacetylene cutting

- Received a commendation from the project manager for consistently meeting production targets with highquality cuts

Certificates

- American Welding Society (AWS) Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certified Welder

- Occupational Safety and Health Administration (OSHA) 30-Hour Construction Safety and Health Training

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oxyacetylene Cutter

- Highlight your experience and skills in oxyacetylene cutting, plasma cutting, and other welding processes.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Oxyacetylene Cutter Resume

- Operate oxyacetylene cutting equipment to cut metal parts according to specifications.

- Read and interpret blueprints and drawings to determine cutting requirements.

- Set up and adjust cutting equipment to ensure proper operation.

- Maintain a clean and organized work area.

- Follow all safety procedures and wear appropriate personal protective equipment.

- Inspect and verify the quality of cut parts.

- Troubleshoot and resolve any issues that may arise during the cutting process.

Frequently Asked Questions (FAQ’s) For Oxyacetylene Cutter

What is oxyacetylene cutting?

Oxyacetylene cutting is a process that uses a mixture of oxygen and acetylene gases to create a flame that can cut through metal. The flame is directed at the metal, and the oxygen reacts with the metal to create an oxide layer. The oxide layer is then blown away by the acetylene, leaving a clean cut.

What are the benefits of oxyacetylene cutting?

Oxyacetylene cutting is a versatile process that can be used to cut a wide variety of metals. It is also a relatively inexpensive process. However, oxyacetylene cutting can also be dangerous if it is not performed properly.

What are the safety precautions that should be taken when using oxyacetylene cutting equipment?

When using oxyacetylene cutting equipment, it is important to wear proper personal protective equipment, such as a welding helmet, gloves, and protective clothing. It is also important to ensure that the work area is well-ventilated.

What are the different types of oxyacetylene cutting tips?

There are a variety of different oxyacetylene cutting tips available, each of which is designed for a specific type of cutting. The most common types of oxyacetylene cutting tips are the straight cutting tip, the bevel cutting tip, and the piercing tip.

What is the difference between oxyacetylene cutting and plasma cutting?

Oxyacetylene cutting and plasma cutting are both processes that can be used to cut metal. However, there are some key differences between the two processes. Oxyacetylene cutting uses a mixture of oxygen and acetylene gases to create a flame, while plasma cutting uses a plasma arc. Plasma cutting is a faster and more precise process than oxyacetylene cutting, but it is also more expensive.