Are you a seasoned Electron Beam Welding Machine Operator seeking a new career path? Discover our professionally built Electron Beam Welding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

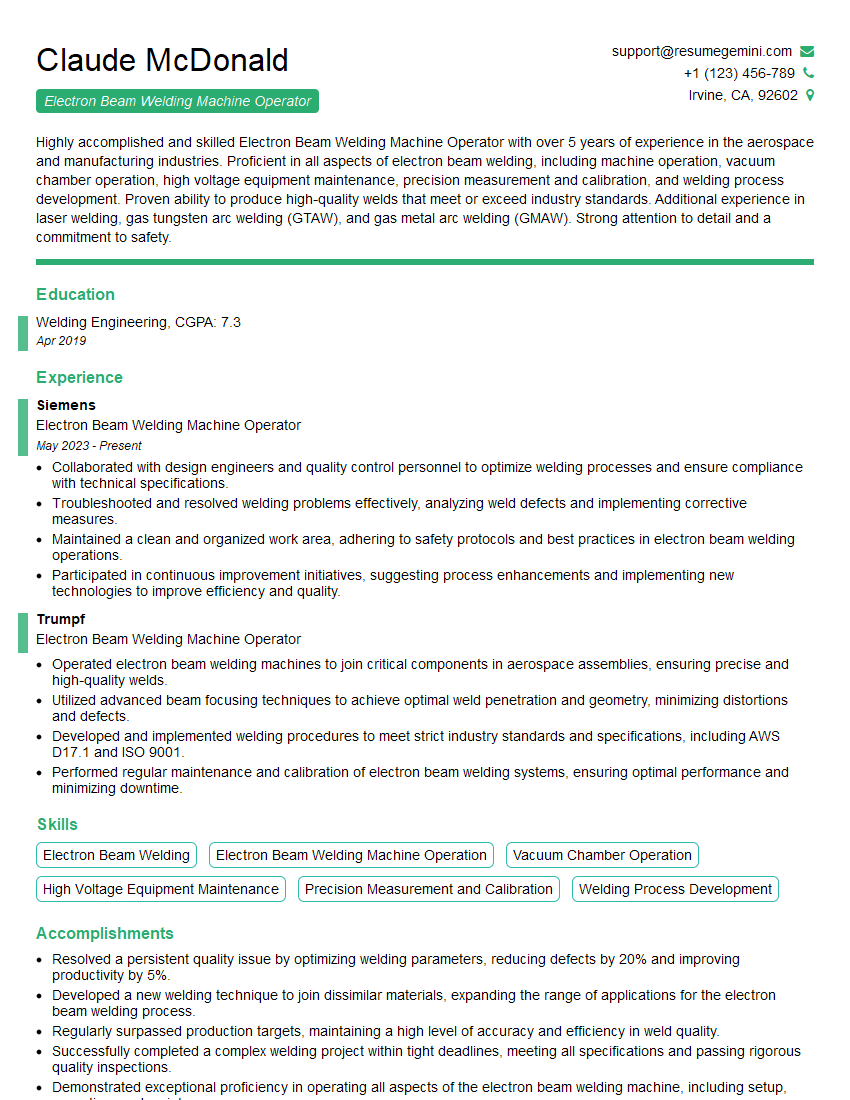

Claude McDonald

Electron Beam Welding Machine Operator

Summary

Highly accomplished and skilled Electron Beam Welding Machine Operator with over 5 years of experience in the aerospace and manufacturing industries. Proficient in all aspects of electron beam welding, including machine operation, vacuum chamber operation, high voltage equipment maintenance, precision measurement and calibration, and welding process development. Proven ability to produce high-quality welds that meet or exceed industry standards. Additional experience in laser welding, gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW). Strong attention to detail and a commitment to safety.

Education

Welding Engineering

April 2019

Skills

- Electron Beam Welding

- Electron Beam Welding Machine Operation

- Vacuum Chamber Operation

- High Voltage Equipment Maintenance

- Precision Measurement and Calibration

- Welding Process Development

Work Experience

Electron Beam Welding Machine Operator

- Collaborated with design engineers and quality control personnel to optimize welding processes and ensure compliance with technical specifications.

- Troubleshooted and resolved welding problems effectively, analyzing weld defects and implementing corrective measures.

- Maintained a clean and organized work area, adhering to safety protocols and best practices in electron beam welding operations.

- Participated in continuous improvement initiatives, suggesting process enhancements and implementing new technologies to improve efficiency and quality.

Electron Beam Welding Machine Operator

- Operated electron beam welding machines to join critical components in aerospace assemblies, ensuring precise and high-quality welds.

- Utilized advanced beam focusing techniques to achieve optimal weld penetration and geometry, minimizing distortions and defects.

- Developed and implemented welding procedures to meet strict industry standards and specifications, including AWS D17.1 and ISO 9001.

- Performed regular maintenance and calibration of electron beam welding systems, ensuring optimal performance and minimizing downtime.

Accomplishments

- Resolved a persistent quality issue by optimizing welding parameters, reducing defects by 20% and improving productivity by 5%.

- Developed a new welding technique to join dissimilar materials, expanding the range of applications for the electron beam welding process.

- Regularly surpassed production targets, maintaining a high level of accuracy and efficiency in weld quality.

- Successfully completed a complex welding project within tight deadlines, meeting all specifications and passing rigorous quality inspections.

- Demonstrated exceptional proficiency in operating all aspects of the electron beam welding machine, including setup, operation, and maintenance.

Awards

- Received the Operator of the Year award for consistently exceeding performance expectations and contributing to the overall success of the welding team.

- Recognized for outstanding contributions to the development of a new electron beam welding process that significantly improved weld quality.

- Awarded the Safety Excellence Award for maintaining a spotless safety record and actively promoting a culture of safety in the workplace.

- Received a Certificate of Excellence for demonstrating exceptional skills and knowledge in the operation of electron beam welding machines.

Certificates

- AWS Certified Welding Inspector

- ASME Boiler and Pressure Vessel Code

- National Institute for Certification in Engineering Technologies (NICET) Level III Welding Inspector

- Society for Automotive Engineers (SAE) Aerospace Material and Process Specification AS5553

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electron Beam Welding Machine Operator

- Highlight your experience in electron beam welding, especially if you have worked on complex or high-value projects.

- Quantify your accomplishments whenever possible. For example, instead of saying “operated electron beam welding machines,” you could say “operated electron beam welding machines to produce high-quality welds that met or exceeded industry standards on a variety of metals, including stainless steel, titanium, and aluminum.”

- Use keywords that potential employers will be searching for, such as “electron beam welding,” “vacuum chamber operation,” and “high voltage equipment maintenance.”

- Proofread your resume carefully before submitting it. Make sure that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Electron Beam Welding Machine Operator Resume

- Set up and operate electron beam welding machines to weld a variety of metals, including stainless steel, titanium, and aluminum.

- Operate vacuum chambers to create and maintain a vacuum environment for electron beam welding.

- Maintain high voltage equipment, including electron guns and power supplies.

- Perform precision measurements and calibrations to ensure that electron beam welding machines are operating correctly.

- Develop and improve electron beam welding processes to increase efficiency and quality.

- Inspect welds to ensure that they meet or exceed industry standards.

Frequently Asked Questions (FAQ’s) For Electron Beam Welding Machine Operator

What is electron beam welding?

Electron beam welding (EBW) is a high-energy welding process that uses a focused beam of electrons to weld metals together. EBW is often used in the aerospace and automotive industries to weld thin materials, such as metal sheets and foils.

What are the advantages of electron beam welding?

EBW offers several advantages over other welding processes, including: – High weld quality: EBW produces welds that are strong, precise, and free of defects. -Minimal heat input: EBW uses a focused beam of electrons, so there is minimal heat input into the workpiece. This helps to prevent distortion and warping of the workpiece. -High speed: EBW is a fast welding process, which can help to reduce manufacturing time and costs.

What are the disadvantages of electron beam welding?

EBW also has some disadvantages, including: -High equipment cost: EBW machines are more expensive than other types of welding machines. -Limited workpiece size: EBW is best suited for welding small workpieces, as the vacuum chamber can only accommodate a limited amount of space. -Safety concerns: EBW machines emit X-rays, so it is important to take safety precautions when operating them.

What are the career prospects for electron beam welding machine operators?

The career prospects for electron beam welding machine operators are good. EBW is a specialized skill that is in high demand in the aerospace and automotive industries. As these industries continue to grow, the demand for electron beam welding machine operators is expected to increase.

How can I become an electron beam welding machine operator?

There are several ways to become an electron beam welding machine operator. You can take a training course at a vocational school or community college. You can also learn on the job by working as an apprentice under an experienced electron beam welding machine operator.

What are the skills required to be an electron beam welding machine operator?

Electron beam welding machine operators need to have a strong understanding of electron beam welding technology and equipment. They also need to be able to read and interpret blueprints and welding specifications. Additionally, they need to have good hand-eye coordination and be able to work in a safe and efficient manner.