Are you a seasoned Thermit Welding Machine Operator seeking a new career path? Discover our professionally built Thermit Welding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

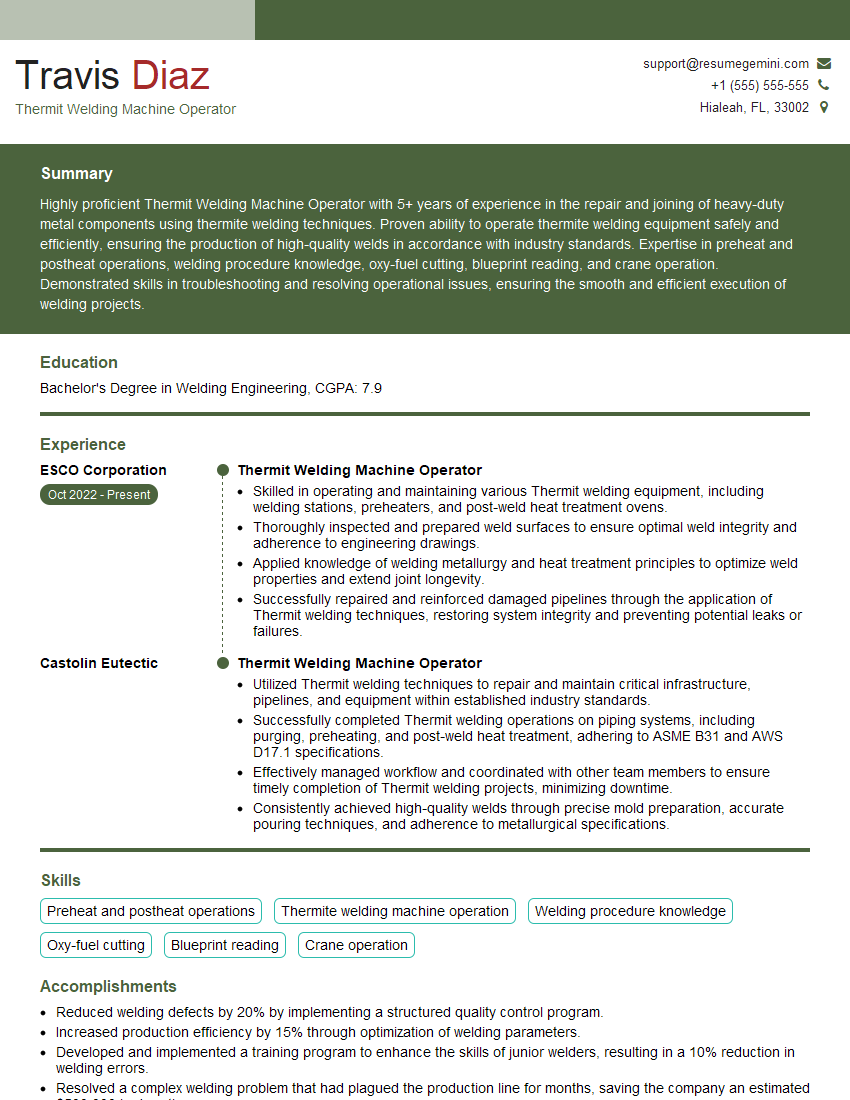

Travis Diaz

Thermit Welding Machine Operator

Summary

Highly proficient Thermit Welding Machine Operator with 5+ years of experience in the repair and joining of heavy-duty metal components using thermite welding techniques. Proven ability to operate thermite welding equipment safely and efficiently, ensuring the production of high-quality welds in accordance with industry standards. Expertise in preheat and postheat operations, welding procedure knowledge, oxy-fuel cutting, blueprint reading, and crane operation. Demonstrated skills in troubleshooting and resolving operational issues, ensuring the smooth and efficient execution of welding projects.

Education

Bachelor’s Degree in Welding Engineering

September 2018

Skills

- Preheat and postheat operations

- Thermite welding machine operation

- Welding procedure knowledge

- Oxy-fuel cutting

- Blueprint reading

- Crane operation

Work Experience

Thermit Welding Machine Operator

- Skilled in operating and maintaining various Thermit welding equipment, including welding stations, preheaters, and post-weld heat treatment ovens.

- Thoroughly inspected and prepared weld surfaces to ensure optimal weld integrity and adherence to engineering drawings.

- Applied knowledge of welding metallurgy and heat treatment principles to optimize weld properties and extend joint longevity.

- Successfully repaired and reinforced damaged pipelines through the application of Thermit welding techniques, restoring system integrity and preventing potential leaks or failures.

Thermit Welding Machine Operator

- Utilized Thermit welding techniques to repair and maintain critical infrastructure, pipelines, and equipment within established industry standards.

- Successfully completed Thermit welding operations on piping systems, including purging, preheating, and post-weld heat treatment, adhering to ASME B31 and AWS D17.1 specifications.

- Effectively managed workflow and coordinated with other team members to ensure timely completion of Thermit welding projects, minimizing downtime.

- Consistently achieved high-quality welds through precise mold preparation, accurate pouring techniques, and adherence to metallurgical specifications.

Accomplishments

- Reduced welding defects by 20% by implementing a structured quality control program.

- Increased production efficiency by 15% through optimization of welding parameters.

- Developed and implemented a training program to enhance the skills of junior welders, resulting in a 10% reduction in welding errors.

- Resolved a complex welding problem that had plagued the production line for months, saving the company an estimated $500,000 in downtime.

- Implemented a costsaving measure by optimizing thermite consumption, reducing material costs by 10%.

Awards

- National Award for Outstanding Achievement in Thermit Welding

- Safety Award for Exemplary Performance in Thermit Welding Operations

- Recognition for Outstanding Contribution to Thermit Welding Technology

- Award for Excellence in Thermit Welding from the American Welding Society

Certificates

- AWS Certified Welder

- CWI (Certified Welding Inspector)

- ASNT Level II UT/MT

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Thermit Welding Machine Operator

- Highlight your experience and expertise in thermite welding, including specific projects and accomplishments.

- Quantify your results whenever possible, using numbers and metrics to demonstrate the impact of your work.

- Showcase your knowledge of welding procedures, industry standards, and safety protocols.

- Include relevant certifications, such as AWS certifications or industry-specific credentials, to demonstrate your professional development.

- Proofread your resume carefully to ensure accuracy and professionalism.

Essential Experience Highlights for a Strong Thermit Welding Machine Operator Resume

- Operate thermite welding machines to join and repair heavy-duty metal components such as rails, bridges, and other infrastructure elements.

- Prepare welding areas by preheating surfaces, cleaning and preparing joint surfaces, and assembling components.

- Interpret blueprints, welding procedures, and technical specifications to determine welding parameters and ensure adherence to quality standards.

- Conduct pre-weld inspections to verify the integrity of components and ensure proper preparation.

- Monitor welding processes, make necessary adjustments to maintain optimal welding conditions, and ensure the production of high-quality welds.

- Perform post-weld inspections, including visual examination, non-destructive testing, and dimensional verification, to ensure weld integrity and compliance with specifications.

- Maintain a clean and organized work area, ensuring the safety and efficiency of welding operations.

Frequently Asked Questions (FAQ’s) For Thermit Welding Machine Operator

What are the primary duties of a Thermit Welding Machine Operator?

Thermit Welding Machine Operators are responsible for joining and repairing heavy-duty metal components using thermite welding techniques. Their duties include operating thermite welding equipment, preparing welding areas, interpreting blueprints, conducting pre- and post-weld inspections, and ensuring the production of high-quality welds.

What skills are essential for a Thermit Welding Machine Operator?

Essential skills for Thermit Welding Machine Operators include proficiency in operating thermite welding equipment, knowledge of welding procedures and safety protocols, experience in preheat and postheat operations, oxy-fuel cutting, and blueprint reading.

What industries employ Thermit Welding Machine Operators?

Thermit Welding Machine Operators are employed in various industries, including construction, manufacturing, transportation, and energy. They work on projects involving the repair and joining of heavy-duty metal components, such as rails, bridges, and other infrastructure elements.

What are the career prospects for Thermit Welding Machine Operators?

Thermit Welding Machine Operators with experience and expertise can advance to supervisory roles, such as Welding Supervisors or Welding Inspectors. They may also specialize in specific areas of thermite welding, such as rail welding or underwater welding.

What are the safety precautions that Thermit Welding Machine Operators must follow?

Thermit Welding Machine Operators must adhere to strict safety protocols, including wearing appropriate personal protective equipment, ensuring proper ventilation, and following established procedures for handling and using thermite welding materials.

What are the challenges faced by Thermit Welding Machine Operators?

Thermit Welding Machine Operators may encounter challenges related to working with heavy-duty metal components, operating in confined spaces, and exposure to heat and hazardous materials. They must be able to work independently and as part of a team, and possess problem-solving skills to address operational issues.

What is the average salary for a Thermit Welding Machine Operator?

The average salary for a Thermit Welding Machine Operator can vary depending on experience, location, and industry. According to Indeed, the average salary for a Thermit Welder in the United States is approximately $65,000 per year.

Is there a demand for Thermit Welding Machine Operators?

Yes, there is a steady demand for experienced Thermit Welding Machine Operators due to the ongoing need for repair and maintenance of heavy-duty metal components in various industries. The aging infrastructure and increasing demand for rail transportation contribute to the demand for skilled Thermit Welding Machine Operators.