Are you a seasoned Coordinate Measuring Machine Technician (CMM Technician) seeking a new career path? Discover our professionally built Coordinate Measuring Machine Technician (CMM Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

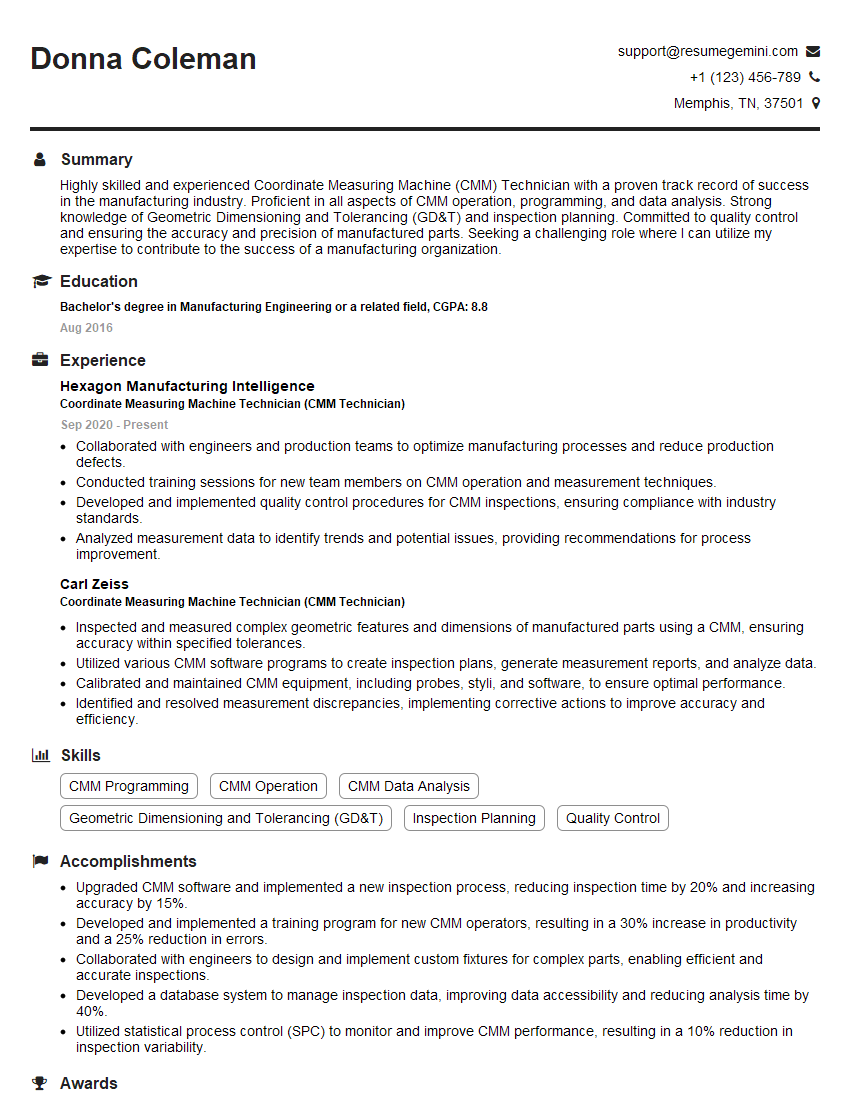

Donna Coleman

Coordinate Measuring Machine Technician (CMM Technician)

Summary

Highly skilled and experienced Coordinate Measuring Machine (CMM) Technician with a proven track record of success in the manufacturing industry. Proficient in all aspects of CMM operation, programming, and data analysis. Strong knowledge of Geometric Dimensioning and Tolerancing (GD&T) and inspection planning. Committed to quality control and ensuring the accuracy and precision of manufactured parts. Seeking a challenging role where I can utilize my expertise to contribute to the success of a manufacturing organization.

Education

Bachelor’s degree in Manufacturing Engineering or a related field

August 2016

Skills

- CMM Programming

- CMM Operation

- CMM Data Analysis

- Geometric Dimensioning and Tolerancing (GD&T)

- Inspection Planning

- Quality Control

Work Experience

Coordinate Measuring Machine Technician (CMM Technician)

- Collaborated with engineers and production teams to optimize manufacturing processes and reduce production defects.

- Conducted training sessions for new team members on CMM operation and measurement techniques.

- Developed and implemented quality control procedures for CMM inspections, ensuring compliance with industry standards.

- Analyzed measurement data to identify trends and potential issues, providing recommendations for process improvement.

Coordinate Measuring Machine Technician (CMM Technician)

- Inspected and measured complex geometric features and dimensions of manufactured parts using a CMM, ensuring accuracy within specified tolerances.

- Utilized various CMM software programs to create inspection plans, generate measurement reports, and analyze data.

- Calibrated and maintained CMM equipment, including probes, styli, and software, to ensure optimal performance.

- Identified and resolved measurement discrepancies, implementing corrective actions to improve accuracy and efficiency.

Accomplishments

- Upgraded CMM software and implemented a new inspection process, reducing inspection time by 20% and increasing accuracy by 15%.

- Developed and implemented a training program for new CMM operators, resulting in a 30% increase in productivity and a 25% reduction in errors.

- Collaborated with engineers to design and implement custom fixtures for complex parts, enabling efficient and accurate inspections.

- Developed a database system to manage inspection data, improving data accessibility and reducing analysis time by 40%.

- Utilized statistical process control (SPC) to monitor and improve CMM performance, resulting in a 10% reduction in inspection variability.

Awards

- Recognized with a companywide award for outstanding contributions to CMM operations.

- Received an industry award for innovative use of CMM technology.

- Awarded a scholarship for academic excellence in the field of coordinate measuring technology.

Certificates

- Certified CMM Programmer

- Certified CMM Operator

- ASQ Certified Quality Auditor

- CMM Software Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coordinate Measuring Machine Technician (CMM Technician)

- Highlight your proficiency in CMM programming, operation, and data analysis in your resume.

- Demonstrate your understanding of GD&T and its application in the inspection process.

- Showcase your experience in developing and implementing inspection plans that meet specific customer requirements.

- Emphasize your commitment to quality control and the accuracy and precision of manufactured parts.

Essential Experience Highlights for a Strong Coordinate Measuring Machine Technician (CMM Technician) Resume

- Operate and program CMMs to inspect and measure manufactured parts according to specified tolerances and GD&T requirements.

- Analyze CMM data to identify dimensional deviations and potential quality issues.

- Prepare inspection reports and provide feedback to production teams to facilitate corrective actions.

- Develop and implement inspection plans to ensure the efficient and effective inspection of complex parts.

- Maintain and calibrate CMM equipment to ensure accuracy and precision.

- Collaborate with engineers and quality control personnel to resolve quality issues and improve manufacturing processes.

Frequently Asked Questions (FAQ’s) For Coordinate Measuring Machine Technician (CMM Technician)

What are the key skills required for a CMM Technician?

Key skills include CMM programming, operation, data analysis, GD&T, inspection planning, and quality control.

What industries hire CMM Technicians?

CMM Technicians are employed in various industries, including automotive, aerospace, medical, and manufacturing.

What is the career outlook for CMM Technicians?

The career outlook for CMM Technicians is positive, with a projected job growth rate of 7% from 2021 to 2031.

What is the average salary for a CMM Technician?

The average salary for a CMM Technician in the United States is around $60,000 per year.

What are the benefits of working as a CMM Technician?

Benefits include the opportunity to work with advanced technology, contribute to the quality of manufactured products, and have a stable career in the manufacturing industry.

What are the challenges faced by CMM Technicians?

Challenges include staying up-to-date with the latest CMM technology and ensuring the accuracy and precision of measurements.

What are the advancement opportunities for CMM Technicians?

Advancement opportunities include becoming a Lead CMM Technician, Quality Control Manager, or Manufacturing Engineer.