Are you a seasoned Bullet Lubricating Machine Operator seeking a new career path? Discover our professionally built Bullet Lubricating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

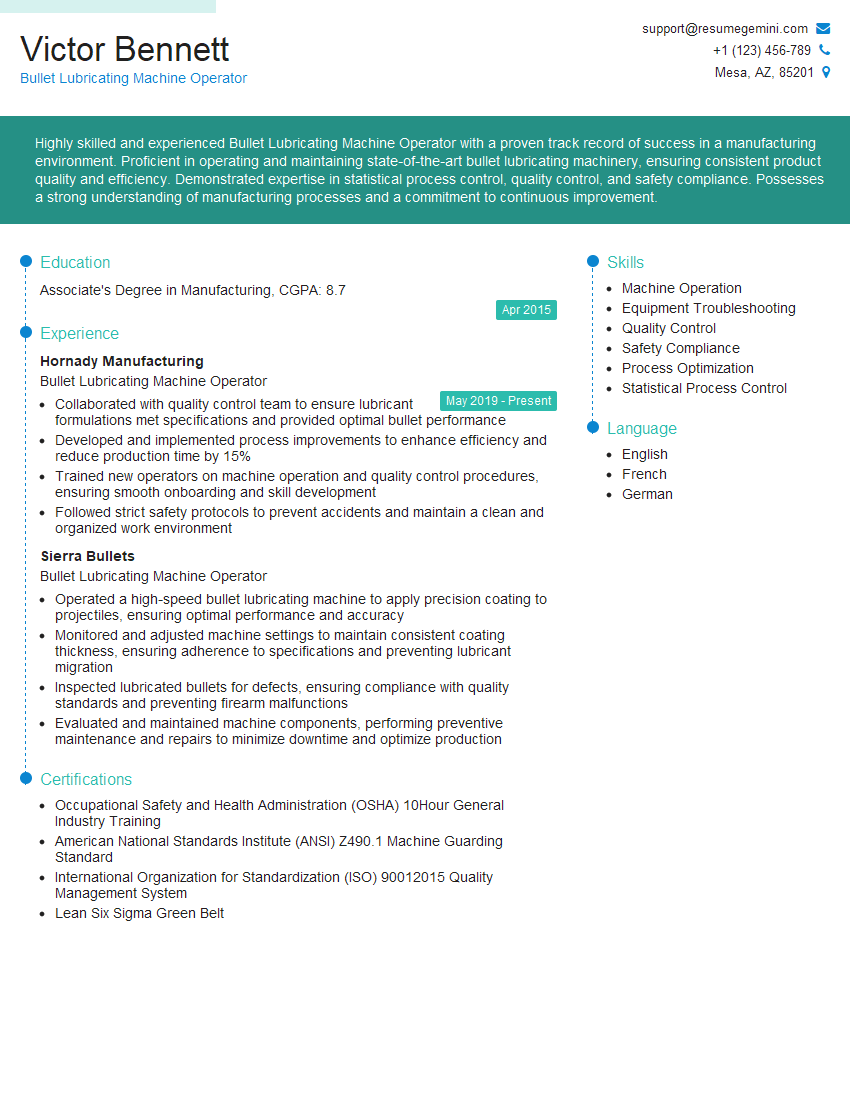

Victor Bennett

Bullet Lubricating Machine Operator

Summary

Highly skilled and experienced Bullet Lubricating Machine Operator with a proven track record of success in a manufacturing environment. Proficient in operating and maintaining state-of-the-art bullet lubricating machinery, ensuring consistent product quality and efficiency. Demonstrated expertise in statistical process control, quality control, and safety compliance. Possesses a strong understanding of manufacturing processes and a commitment to continuous improvement.

Education

Associate’s Degree in Manufacturing

April 2015

Skills

- Machine Operation

- Equipment Troubleshooting

- Quality Control

- Safety Compliance

- Process Optimization

- Statistical Process Control

Work Experience

Bullet Lubricating Machine Operator

- Collaborated with quality control team to ensure lubricant formulations met specifications and provided optimal bullet performance

- Developed and implemented process improvements to enhance efficiency and reduce production time by 15%

- Trained new operators on machine operation and quality control procedures, ensuring smooth onboarding and skill development

- Followed strict safety protocols to prevent accidents and maintain a clean and organized work environment

Bullet Lubricating Machine Operator

- Operated a high-speed bullet lubricating machine to apply precision coating to projectiles, ensuring optimal performance and accuracy

- Monitored and adjusted machine settings to maintain consistent coating thickness, ensuring adherence to specifications and preventing lubricant migration

- Inspected lubricated bullets for defects, ensuring compliance with quality standards and preventing firearm malfunctions

- Evaluated and maintained machine components, performing preventive maintenance and repairs to minimize downtime and optimize production

Certificates

- Occupational Safety and Health Administration (OSHA) 10Hour General Industry Training

- American National Standards Institute (ANSI) Z490.1 Machine Guarding Standard

- International Organization for Standardization (ISO) 90012015 Quality Management System

- Lean Six Sigma Green Belt

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bullet Lubricating Machine Operator

- Highlight your experience operating and maintaining bullet lubricating machinery.

- Quantify your accomplishments in terms of improved efficiency, reduced downtime, and enhanced product quality.

- Demonstrate your knowledge of statistical process control and quality control techniques.

- Emphasize your commitment to safety and compliance.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Bullet Lubricating Machine Operator Resume

- Operate and maintain bullet lubricating machines to apply lubrication to bullets.

- Monitor and adjust machine settings to ensure optimal performance and product quality.

- Perform routine maintenance and troubleshooting on machinery to minimize downtime.

- Conduct quality control inspections to ensure bullets meet specifications.

- Implement process improvements to enhance efficiency and reduce waste.

- Comply with all safety regulations and protocols to maintain a safe work environment.

- Work effectively as part of a team and communicate clearly with colleagues.

Frequently Asked Questions (FAQ’s) For Bullet Lubricating Machine Operator

What are the key skills required for a Bullet Lubricating Machine Operator?

Key skills for a Bullet Lubricating Machine Operator include machine operation, equipment troubleshooting, quality control, safety compliance, process optimization, and statistical process control.

What are the job responsibilities of a Bullet Lubricating Machine Operator?

Responsibilities of a Bullet Lubricating Machine Operator include operating and maintaining bullet lubricating machines, monitoring and adjusting machine settings, performing routine maintenance and troubleshooting, conducting quality control inspections, implementing process improvements, complying with safety regulations, and working effectively as part of a team.

What are the top companies that hire Bullet Lubricating Machine Operators?

Top companies that hire Bullet Lubricating Machine Operators include Hornady Manufacturing and Sierra Bullets.

What is the educational background required to become a Bullet Lubricating Machine Operator?

An Associate’s Degree in Manufacturing is a common educational background for Bullet Lubricating Machine Operators.

What is the salary range for a Bullet Lubricating Machine Operator?

The salary range for a Bullet Lubricating Machine Operator varies depending on experience, location, and company. According to Indeed, the average salary for a Bullet Lubricating Machine Operator in the United States is around $40,000 per year.

What are the career prospects for a Bullet Lubricating Machine Operator?

With experience and additional training, Bullet Lubricating Machine Operators can advance to positions such as Machine Supervisor, Quality Control Manager, or Production Manager.

What are the safety precautions that a Bullet Lubricating Machine Operator should follow?

Safety precautions for a Bullet Lubricating Machine Operator include wearing proper protective gear, following lockout/tagout procedures, and being aware of the potential hazards of the machinery and materials used.

What are the industry trends that are affecting Bullet Lubricating Machine Operators?

Industry trends that are affecting Bullet Lubricating Machine Operators include the increasing use of automation and the growing demand for high-quality ammunition.