Are you a seasoned Electrical Discharge Machine Operator seeking a new career path? Discover our professionally built Electrical Discharge Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

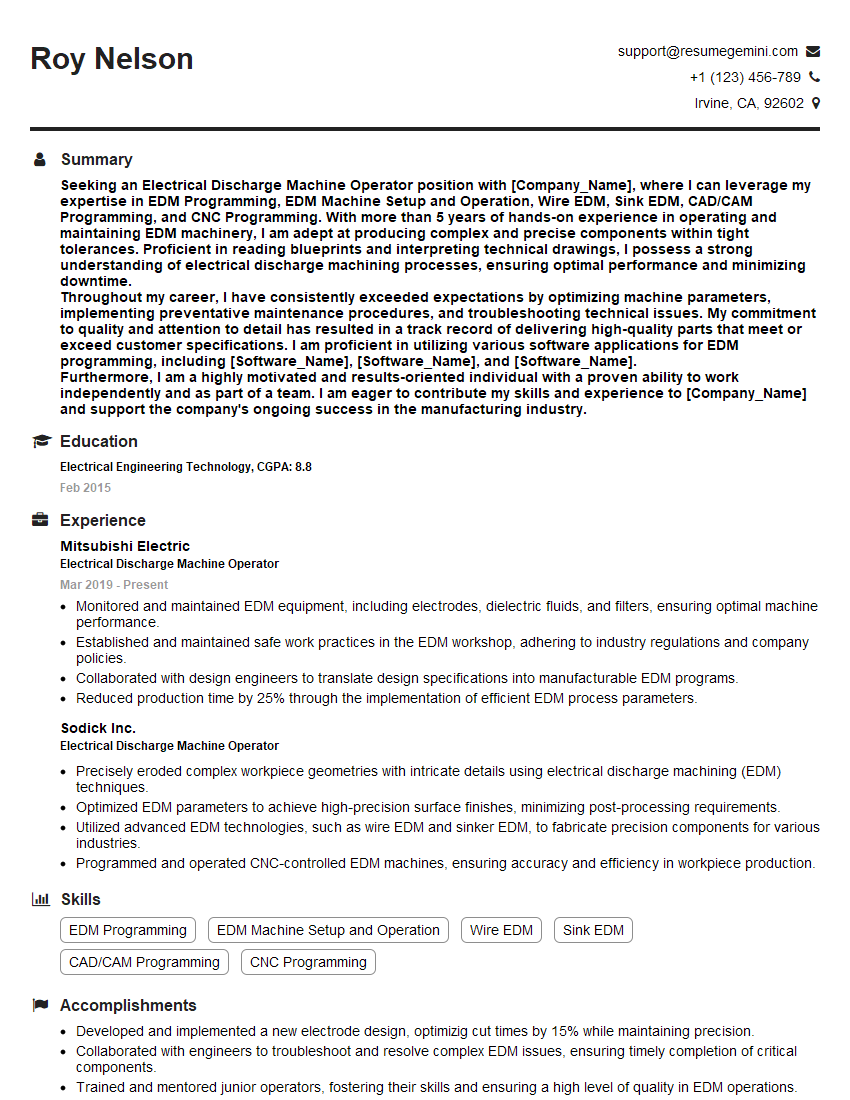

Roy Nelson

Electrical Discharge Machine Operator

Summary

Seeking an Electrical Discharge Machine Operator position with [Company_Name], where I can leverage my expertise in EDM Programming, EDM Machine Setup and Operation, Wire EDM, Sink EDM, CAD/CAM Programming, and CNC Programming. With more than 5 years of hands-on experience in operating and maintaining EDM machinery, I am adept at producing complex and precise components within tight tolerances. Proficient in reading blueprints and interpreting technical drawings, I possess a strong understanding of electrical discharge machining processes, ensuring optimal performance and minimizing downtime.

Throughout my career, I have consistently exceeded expectations by optimizing machine parameters, implementing preventative maintenance procedures, and troubleshooting technical issues. My commitment to quality and attention to detail has resulted in a track record of delivering high-quality parts that meet or exceed customer specifications. I am proficient in utilizing various software applications for EDM programming, including [Software_Name], [Software_Name], and [Software_Name].

Furthermore, I am a highly motivated and results-oriented individual with a proven ability to work independently and as part of a team. I am eager to contribute my skills and experience to [Company_Name] and support the company’s ongoing success in the manufacturing industry.

Education

Electrical Engineering Technology

February 2015

Skills

- EDM Programming

- EDM Machine Setup and Operation

- Wire EDM

- Sink EDM

- CAD/CAM Programming

- CNC Programming

Work Experience

Electrical Discharge Machine Operator

- Monitored and maintained EDM equipment, including electrodes, dielectric fluids, and filters, ensuring optimal machine performance.

- Established and maintained safe work practices in the EDM workshop, adhering to industry regulations and company policies.

- Collaborated with design engineers to translate design specifications into manufacturable EDM programs.

- Reduced production time by 25% through the implementation of efficient EDM process parameters.

Electrical Discharge Machine Operator

- Precisely eroded complex workpiece geometries with intricate details using electrical discharge machining (EDM) techniques.

- Optimized EDM parameters to achieve high-precision surface finishes, minimizing post-processing requirements.

- Utilized advanced EDM technologies, such as wire EDM and sinker EDM, to fabricate precision components for various industries.

- Programmed and operated CNC-controlled EDM machines, ensuring accuracy and efficiency in workpiece production.

Accomplishments

- Developed and implemented a new electrode design, optimizig cut times by 15% while maintaining precision.

- Collaborated with engineers to troubleshoot and resolve complex EDM issues, ensuring timely completion of critical components.

- Trained and mentored junior operators, fostering their skills and ensuring a high level of quality in EDM operations.

- Proactively identified and resolved potential machine malfunctions, preventing unplanned downtime and ensuring maximum production efficiency.

- Utilized advanced EDM software to simulate and optimize electrode paths, reducing cycle times and enhancing precision.

Awards

- Excellence Award for Superior EDM Performance, recognized for consistently exceeding production targets.

- Employee of the Quarter for implementing a lean manufacturing process, resulting in a 10% increase in productivity.

- Safety Star Award for maintaining an impeccable safety record and contributing to a positive safety culture in the workplace.

- Industry Innovation Award for developing a novel EDM technique that significantly improved surface finish and reduced postprocessing time.

Certificates

- Certified EDM Operator (CEO)

- Certified Manufacturing Technologist (CMfgT)

- ISO 9001:2015

- AS9100:D

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrical Discharge Machine Operator

Highlight your technical skills and expertise in EDM programming, machine setup, and operation.

Showcase your experience in reading and interpreting blueprints and technical drawings.

Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

Emphasize your commitment to quality and attention to detail, highlighting your ability to produce high-precision components that meet or exceed customer specifications.

Include relevant keywords throughout your resume to optimize its visibility for potential employers.

Essential Experience Highlights for a Strong Electrical Discharge Machine Operator Resume

- Operate and maintain electrical discharge machines (EDM), including wire EDM and sink EDM, to produce complex and precise components according to specifications.

- Interpret blueprints, technical drawings, and schematics to determine machining parameters, tooling requirements, and production sequences.

- Program and set up EDM machines, ensuring optimal cutting conditions, feed rates, and electrode configurations.

- Monitor EDM processes, make adjustments as needed, and troubleshoot any technical issues that arise to minimize downtime and ensure production efficiency.

- Inspect and measure machined parts using precision measuring instruments to verify conformance to specifications and maintain quality standards.

- Maintain a clean and organized work area, adhering to safety regulations and best practices to ensure a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Electrical Discharge Machine Operator

What are the essential skills and qualifications required for an Electrical Discharge Machine Operator?

Essential skills and qualifications for an Electrical Discharge Machine Operator include: – Proficiency in EDM programming, EDM machine setup and operation – Experience in operating wire EDM and sink EDM machines – Ability to read and interpret blueprints, technical drawings, and schematics – Knowledge of electrical discharge machining processes and principles – Strong attention to detail and commitment to quality – Excellent troubleshooting and problem-solving skills

What are the primary responsibilities of an Electrical Discharge Machine Operator?

The primary responsibilities of an Electrical Discharge Machine Operator include: – Operating and maintaining EDM machinery to produce complex and precise components – Interpreting blueprints and technical drawings to determine machining parameters – Programming and setting up EDM machines to optimize cutting conditions – Monitoring EDM processes, making adjustments, and troubleshooting technical issues – Inspecting and measuring machined parts to verify conformance to specifications – Maintaining a clean and organized work area, adhering to safety regulations

What are the career advancement opportunities for an Electrical Discharge Machine Operator?

Electrical Discharge Machine Operators can advance their careers by: – Gaining experience and expertise in operating and programming more advanced EDM machines – Acquiring certifications or specialized training in EDM technology – Taking on supervisory or leadership roles within the manufacturing industry – Pursuing a higher education, such as an associate’s degree or bachelor’s degree in manufacturing engineering or a related field

What are the key factors to consider when writing a standout resume for an Electrical Discharge Machine Operator position?

When writing a standout resume for an Electrical Discharge Machine Operator position, consider the following factors: – Highlight your technical skills and expertise in EDM programming, machine setup, and operation – Showcase your experience in reading and interpreting blueprints and technical drawings – Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact – Emphasize your commitment to quality and attention to detail, highlighting your ability to produce high-precision components that meet or exceed customer specifications – Include relevant keywords throughout your resume to optimize its visibility for potential employers

What are the typical work hours for an Electrical Discharge Machine Operator?

Electrical Discharge Machine Operators typically work regular business hours, such as 8:00 AM to 5:00 PM, Monday through Friday. However, overtime may be required on occasion, especially during peak production periods or to meet deadlines.

What is the job outlook for Electrical Discharge Machine Operators?

The job outlook for Electrical Discharge Machine Operators is expected to be good over the next few years. The increasing demand for precision-machined components in various industries, such as aerospace, automotive, and????, is driving the growth in this field. As companies continue to invest in advanced manufacturing technologies, the need for skilled EDM operators will remain strong.

What is the earning potential for Electrical Discharge Machine Operators?

The earning potential for Electrical Discharge Machine Operators varies depending on factors such as experience, skill level, location, and industry. According to [website_name], the average annual salary for EDM operators is around [amount]. However, experienced operators with specialized skills and certifications can earn significantly more.