Are you a seasoned Electrolytic Etcher seeking a new career path? Discover our professionally built Electrolytic Etcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

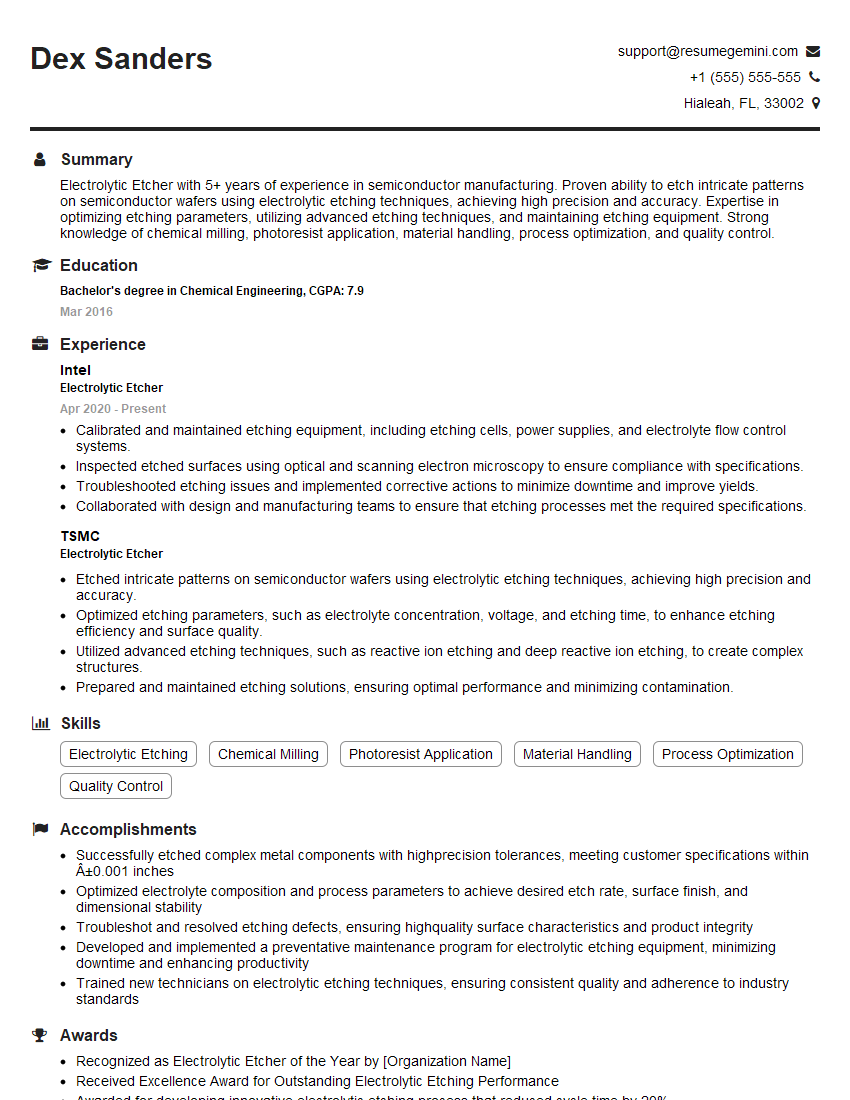

Dex Sanders

Electrolytic Etcher

Summary

Electrolytic Etcher with 5+ years of experience in semiconductor manufacturing. Proven ability to etch intricate patterns on semiconductor wafers using electrolytic etching techniques, achieving high precision and accuracy. Expertise in optimizing etching parameters, utilizing advanced etching techniques, and maintaining etching equipment. Strong knowledge of chemical milling, photoresist application, material handling, process optimization, and quality control.

Education

Bachelor’s degree in Chemical Engineering

March 2016

Skills

- Electrolytic Etching

- Chemical Milling

- Photoresist Application

- Material Handling

- Process Optimization

- Quality Control

Work Experience

Electrolytic Etcher

- Calibrated and maintained etching equipment, including etching cells, power supplies, and electrolyte flow control systems.

- Inspected etched surfaces using optical and scanning electron microscopy to ensure compliance with specifications.

- Troubleshooted etching issues and implemented corrective actions to minimize downtime and improve yields.

- Collaborated with design and manufacturing teams to ensure that etching processes met the required specifications.

Electrolytic Etcher

- Etched intricate patterns on semiconductor wafers using electrolytic etching techniques, achieving high precision and accuracy.

- Optimized etching parameters, such as electrolyte concentration, voltage, and etching time, to enhance etching efficiency and surface quality.

- Utilized advanced etching techniques, such as reactive ion etching and deep reactive ion etching, to create complex structures.

- Prepared and maintained etching solutions, ensuring optimal performance and minimizing contamination.

Accomplishments

- Successfully etched complex metal components with highprecision tolerances, meeting customer specifications within ±0.001 inches

- Optimized electrolyte composition and process parameters to achieve desired etch rate, surface finish, and dimensional stability

- Troubleshot and resolved etching defects, ensuring highquality surface characteristics and product integrity

- Developed and implemented a preventative maintenance program for electrolytic etching equipment, minimizing downtime and enhancing productivity

- Trained new technicians on electrolytic etching techniques, ensuring consistent quality and adherence to industry standards

Awards

- Recognized as Electrolytic Etcher of the Year by [Organization Name]

- Received Excellence Award for Outstanding Electrolytic Etching Performance

- Awarded for developing innovative electrolytic etching process that reduced cycle time by 20%

Certificates

- Certified Electrolytic Etcher

- ISO 9001 Auditor

- ASME B46.1 Inspector

- NADCAP Approved Etcher

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrolytic Etcher

- Highlight your experience in etching intricate patterns on semiconductor wafers using electrolytic etching techniques.

- Quantify your achievements in optimizing etching parameters and improving etching efficiency.

- Showcase your expertise in advanced etching techniques, such as reactive ion etching and deep reactive ion etching.

- Emphasize your ability to troubleshoot etching issues and implement corrective actions to minimize downtime.

Essential Experience Highlights for a Strong Electrolytic Etcher Resume

- Etched intricate patterns on semiconductor wafers using electrolytic etching techniques, achieving high precision and accuracy.

- Optimized etching parameters, such as electrolyte concentration, voltage, and etching time, to enhance etching efficiency and surface quality.

- Utilized advanced etching techniques, such as reactive ion etching and deep reactive ion etching, to create complex structures.

- Prepared and maintained etching solutions, ensuring optimal performance and minimizing contamination.

- Inspected etched surfaces using optical and scanning electron microscopy to ensure compliance with specifications.

- Troubleshooted etching issues and implemented corrective actions to minimize downtime and improve yields.

- Collaborated with design and manufacturing teams to ensure that etching processes met the required specifications.

Frequently Asked Questions (FAQ’s) For Electrolytic Etcher

What are the key skills required to be an Electrolytic Etcher?

The key skills required to be an Electrolytic Etcher include electrolytic etching, chemical milling, photoresist application, material handling, process optimization, and quality control.

What is the role of an Electrolytic Etcher in the semiconductor manufacturing process?

An Electrolytic Etcher is responsible for etching intricate patterns on semiconductor wafers using electrolytic etching techniques to create complex structures.

What are the different types of etching techniques used by Electrolytic Etchers?

Electrolytic Etchers use various etching techniques, including electrolytic etching, reactive ion etching, and deep reactive ion etching.

What is the importance of optimizing etching parameters in electrolytic etching?

Optimizing etching parameters is crucial in electrolytic etching as it helps enhance etching efficiency, surface quality, and minimize defects.

How do Electrolytic Etchers ensure the quality of etched surfaces?

Electrolytic Etchers ensure the quality of etched surfaces by inspecting them using optical and scanning electron microscopy to verify compliance with specifications.

What are the career prospects for Electrolytic Etchers?

Electrolytic Etchers with experience and expertise in advanced etching techniques can progress to supervisory or managerial roles in the semiconductor manufacturing industry.