Are you a seasoned Fabric Machine Operator seeking a new career path? Discover our professionally built Fabric Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

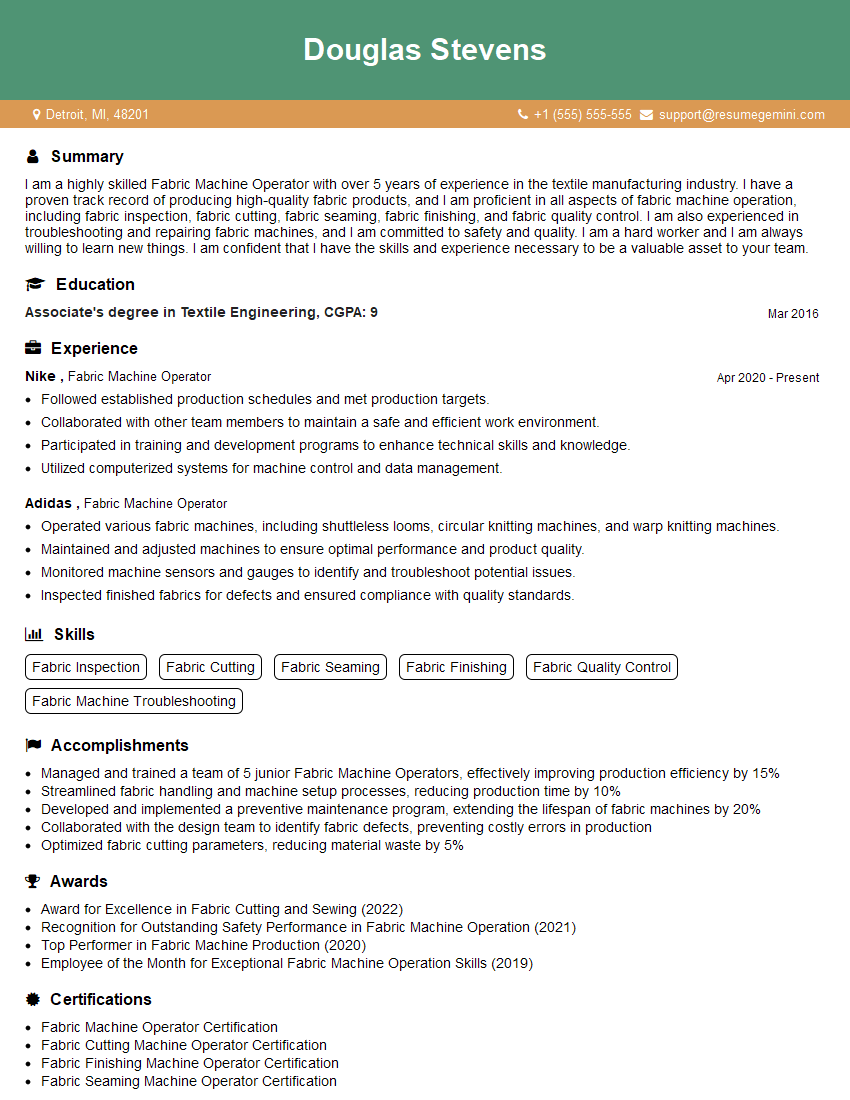

Douglas Stevens

Fabric Machine Operator

Summary

I am a highly skilled Fabric Machine Operator with over 5 years of experience in the textile manufacturing industry. I have a proven track record of producing high-quality fabric products, and I am proficient in all aspects of fabric machine operation, including fabric inspection, fabric cutting, fabric seaming, fabric finishing, and fabric quality control. I am also experienced in troubleshooting and repairing fabric machines, and I am committed to safety and quality. I am a hard worker and I am always willing to learn new things. I am confident that I have the skills and experience necessary to be a valuable asset to your team.

Education

Associate’s degree in Textile Engineering

March 2016

Skills

- Fabric Inspection

- Fabric Cutting

- Fabric Seaming

- Fabric Finishing

- Fabric Quality Control

- Fabric Machine Troubleshooting

Work Experience

Fabric Machine Operator

- Followed established production schedules and met production targets.

- Collaborated with other team members to maintain a safe and efficient work environment.

- Participated in training and development programs to enhance technical skills and knowledge.

- Utilized computerized systems for machine control and data management.

Fabric Machine Operator

- Operated various fabric machines, including shuttleless looms, circular knitting machines, and warp knitting machines.

- Maintained and adjusted machines to ensure optimal performance and product quality.

- Monitored machine sensors and gauges to identify and troubleshoot potential issues.

- Inspected finished fabrics for defects and ensured compliance with quality standards.

Accomplishments

- Managed and trained a team of 5 junior Fabric Machine Operators, effectively improving production efficiency by 15%

- Streamlined fabric handling and machine setup processes, reducing production time by 10%

- Developed and implemented a preventive maintenance program, extending the lifespan of fabric machines by 20%

- Collaborated with the design team to identify fabric defects, preventing costly errors in production

- Optimized fabric cutting parameters, reducing material waste by 5%

Awards

- Award for Excellence in Fabric Cutting and Sewing (2022)

- Recognition for Outstanding Safety Performance in Fabric Machine Operation (2021)

- Top Performer in Fabric Machine Production (2020)

- Employee of the Month for Exceptional Fabric Machine Operation Skills (2019)

Certificates

- Fabric Machine Operator Certification

- Fabric Cutting Machine Operator Certification

- Fabric Finishing Machine Operator Certification

- Fabric Seaming Machine Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fabric Machine Operator

- Highlight your skills and experience in your resume objective.

- Use action verbs to describe your accomplishments.

- Be specific about the types of fabric machines you have operated.

- Include any certifications or training you have received.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Fabric Machine Operator Resume

- Inspect fabric for defects before it is cut and sewn.

- Cut fabric according to patterns and specifications.

- Seam fabric together using a sewing machine.

- Finish fabric by pressing it and trimming any loose threads.

- Ensure that all fabric products meet quality standards.

- Troubleshoot and repair fabric machines.

- Follow all safety procedures.

Frequently Asked Questions (FAQ’s) For Fabric Machine Operator

What is a Fabric Machine Operator?

A Fabric Machine Operator is responsible for operating fabric machines to produce fabric products. This may include cutting, sewing, and finishing fabric.

What are the different types of fabric machines?

There are many different types of fabric machines, including cutting machines, sewing machines, and finishing machines.

What are the qualifications for becoming a Fabric Machine Operator?

Most Fabric Machine Operators have a high school diploma or equivalent. Some employers may require a post-secondary degree in textile engineering or a related field.

What are the job duties of a Fabric Machine Operator?

The job duties of a Fabric Machine Operator may include inspecting fabric for defects, cutting fabric according to patterns, sewing fabric together, finishing fabric by pressing it and trimming any loose threads, and troubleshooting and repairing fabric machines.

What is the work environment of a Fabric Machine Operator?

Fabric Machine Operators typically work in a factory or manufacturing setting. They may be exposed to noise, dust, and fumes.

What is the salary of a Fabric Machine Operator?

The salary of a Fabric Machine Operator varies depending on experience, location, and employer. According to Indeed, the average salary for a Fabric Machine Operator in the United States is $16.50 per hour.