Are you a seasoned Metal Rivet Machine Operator seeking a new career path? Discover our professionally built Metal Rivet Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

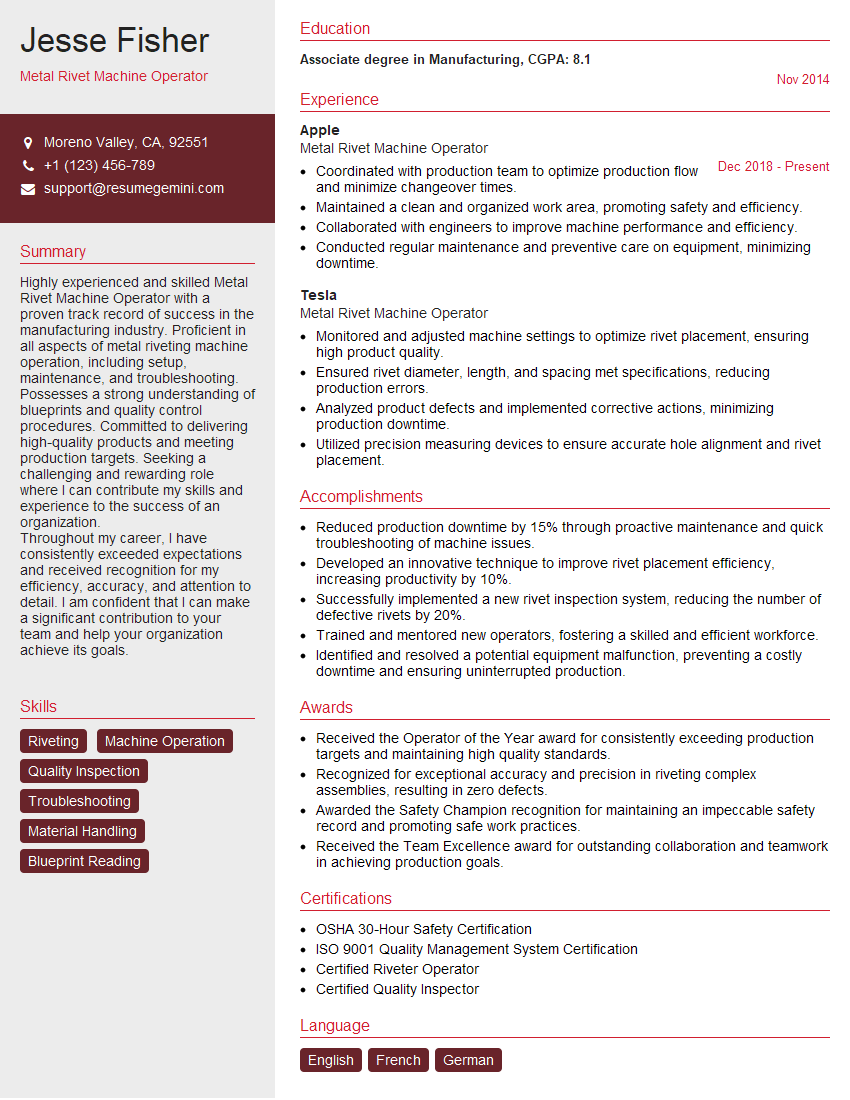

Jesse Fisher

Metal Rivet Machine Operator

Summary

Highly experienced and skilled Metal Rivet Machine Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of metal riveting machine operation, including setup, maintenance, and troubleshooting. Possesses a strong understanding of blueprints and quality control procedures. Committed to delivering high-quality products and meeting production targets. Seeking a challenging and rewarding role where I can contribute my skills and experience to the success of an organization.

Throughout my career, I have consistently exceeded expectations and received recognition for my efficiency, accuracy, and attention to detail. I am confident that I can make a significant contribution to your team and help your organization achieve its goals.

Education

Associate degree in Manufacturing

November 2014

Skills

- Riveting

- Machine Operation

- Quality Inspection

- Troubleshooting

- Material Handling

- Blueprint Reading

Work Experience

Metal Rivet Machine Operator

- Coordinated with production team to optimize production flow and minimize changeover times.

- Maintained a clean and organized work area, promoting safety and efficiency.

- Collaborated with engineers to improve machine performance and efficiency.

- Conducted regular maintenance and preventive care on equipment, minimizing downtime.

Metal Rivet Machine Operator

- Monitored and adjusted machine settings to optimize rivet placement, ensuring high product quality.

- Ensured rivet diameter, length, and spacing met specifications, reducing production errors.

- Analyzed product defects and implemented corrective actions, minimizing production downtime.

- Utilized precision measuring devices to ensure accurate hole alignment and rivet placement.

Accomplishments

- Reduced production downtime by 15% through proactive maintenance and quick troubleshooting of machine issues.

- Developed an innovative technique to improve rivet placement efficiency, increasing productivity by 10%.

- Successfully implemented a new rivet inspection system, reducing the number of defective rivets by 20%.

- Trained and mentored new operators, fostering a skilled and efficient workforce.

- Identified and resolved a potential equipment malfunction, preventing a costly downtime and ensuring uninterrupted production.

Awards

- Received the Operator of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for exceptional accuracy and precision in riveting complex assemblies, resulting in zero defects.

- Awarded the Safety Champion recognition for maintaining an impeccable safety record and promoting safe work practices.

- Received the Team Excellence award for outstanding collaboration and teamwork in achieving production goals.

Certificates

- OSHA 30-Hour Safety Certification

- ISO 9001 Quality Management System Certification

- Certified Riveter Operator

- Certified Quality Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Rivet Machine Operator

- Highlight your experience and skills in operating metal riveting machines.

- Showcase your knowledge of blueprints and quality control procedures.

- Emphasize your ability to troubleshoot and resolve machine malfunctions.

- Demonstrate your commitment to safety and efficiency.

Essential Experience Highlights for a Strong Metal Rivet Machine Operator Resume

- Operate and maintain metal riveting machines to produce high-quality products

- Set up and adjust machines according to blueprints and specifications

- Inspect materials and finished products to ensure they meet quality standards

- Troubleshoot and resolve machine malfunctions to minimize downtime

- Handle and move materials safely and efficiently

- Adhere to all safety protocols and procedures

- Maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Metal Rivet Machine Operator

What are the primary responsibilities of a Metal Rivet Machine Operator?

The primary responsibilities of a Metal Rivet Machine Operator include operating and maintaining metal riveting machines, setting up and adjusting machines according to blueprints and specifications, inspecting materials and finished products to ensure they meet quality standards, troubleshooting and resolving machine malfunctions, handling and moving materials safely and efficiently, adhering to all safety protocols and procedures, and maintaining a clean and organized work area.

What are the educational requirements for a Metal Rivet Machine Operator?

While formal education requirements may vary depending on the specific employer, many Metal Rivet Machine Operators hold an associate degree in Manufacturing or a related field.

What skills are necessary to be successful as a Metal Rivet Machine Operator?

Essential skills for a Metal Rivet Machine Operator include proficiency in operating metal riveting machines, the ability to read and interpret blueprints, knowledge of quality control procedures, troubleshooting and problem-solving skills, and a strong attention to detail.

What are the career prospects for a Metal Rivet Machine Operator?

Metal Rivet Machine Operators can advance to supervisory or management positions within the manufacturing industry. With experience and additional training, they may also pursue roles in quality control or engineering.

What is the work environment of a Metal Rivet Machine Operator like?

Metal Rivet Machine Operators typically work in manufacturing facilities, operating riveting machines in a production environment. The work may involve repetitive tasks and can be physically demanding, requiring standing for long periods and handling heavy materials.

How can I improve my chances of getting hired as a Metal Rivet Machine Operator?

To improve your chances of getting hired as a Metal Rivet Machine Operator, focus on developing your skills and experience in operating metal riveting machines, reading blueprints, and maintaining quality control standards. Additionally, highlight your ability to work independently and as part of a team, and emphasize your commitment to safety and efficiency.

What are the safety precautions that Metal Rivet Machine Operators should take?

Metal Rivet Machine Operators should always wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs. They should also be trained on the safe operation of riveting machines and follow all established safety protocols. Additionally, they should be aware of potential hazards such as moving machinery, sharp edges, and hot surfaces.

What is the typical salary range for a Metal Rivet Machine Operator?

The salary range for a Metal Rivet Machine Operator can vary depending on factors such as experience, location, and employer. According to Indeed, the average salary for a Metal Rivet Machine Operator in the United States is approximately $20 per hour.