Are you a seasoned Plastic Finisher seeking a new career path? Discover our professionally built Plastic Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

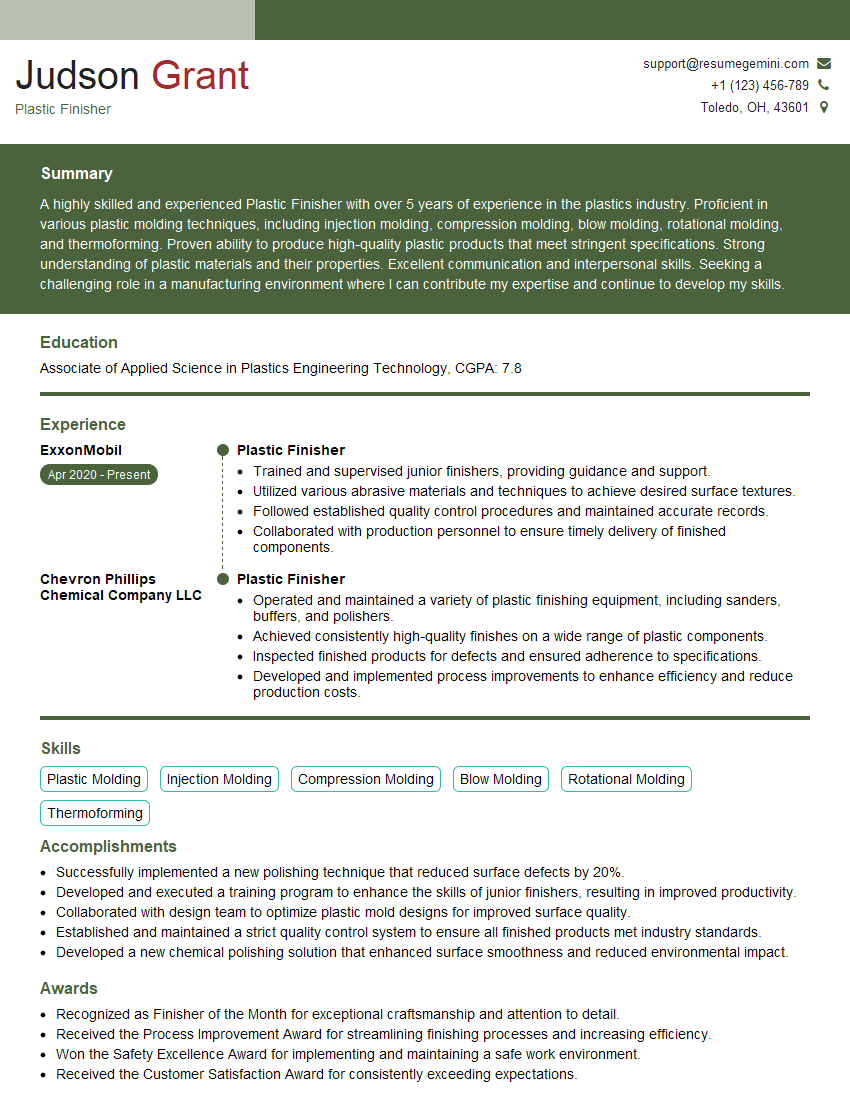

Judson Grant

Plastic Finisher

Summary

A highly skilled and experienced Plastic Finisher with over 5 years of experience in the plastics industry. Proficient in various plastic molding techniques, including injection molding, compression molding, blow molding, rotational molding, and thermoforming. Proven ability to produce high-quality plastic products that meet stringent specifications. Strong understanding of plastic materials and their properties. Excellent communication and interpersonal skills. Seeking a challenging role in a manufacturing environment where I can contribute my expertise and continue to develop my skills.

Education

Associate of Applied Science in Plastics Engineering Technology

March 2016

Skills

- Plastic Molding

- Injection Molding

- Compression Molding

- Blow Molding

- Rotational Molding

- Thermoforming

Work Experience

Plastic Finisher

- Trained and supervised junior finishers, providing guidance and support.

- Utilized various abrasive materials and techniques to achieve desired surface textures.

- Followed established quality control procedures and maintained accurate records.

- Collaborated with production personnel to ensure timely delivery of finished components.

Plastic Finisher

- Operated and maintained a variety of plastic finishing equipment, including sanders, buffers, and polishers.

- Achieved consistently high-quality finishes on a wide range of plastic components.

- Inspected finished products for defects and ensured adherence to specifications.

- Developed and implemented process improvements to enhance efficiency and reduce production costs.

Accomplishments

- Successfully implemented a new polishing technique that reduced surface defects by 20%.

- Developed and executed a training program to enhance the skills of junior finishers, resulting in improved productivity.

- Collaborated with design team to optimize plastic mold designs for improved surface quality.

- Established and maintained a strict quality control system to ensure all finished products met industry standards.

- Developed a new chemical polishing solution that enhanced surface smoothness and reduced environmental impact.

Awards

- Recognized as Finisher of the Month for exceptional craftsmanship and attention to detail.

- Received the Process Improvement Award for streamlining finishing processes and increasing efficiency.

- Won the Safety Excellence Award for implementing and maintaining a safe work environment.

- Received the Customer Satisfaction Award for consistently exceeding expectations.

Certificates

- Certified Plastic Processor (CPP)

- Certified Plastics Technician (CPT)

- Certified Plastics Welder (CPW)

- Certified Plastics Finisher (CPF)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Finisher

- Highlight your technical skills and experience in various plastic molding techniques.

- Showcase your knowledge of plastic materials and their properties.

- Emphasize your ability to troubleshoot and resolve production problems.

- Demonstrate your commitment to safety and quality.

- Quantify your accomplishments whenever possible to showcase your impact.

Essential Experience Highlights for a Strong Plastic Finisher Resume

- Operate and maintain plastic molding equipment, ensuring optimal performance and product quality.

- Inspect and measure plastic products to ensure they meet specifications.

- Troubleshoot and resolve production problems to minimize downtime.

- Maintain a clean and organized work area, adhering to safety protocols.

- Work effectively in a team environment and communicate clearly with colleagues.

- Stay up-to-date on the latest plastic molding technologies and best practices.

Frequently Asked Questions (FAQ’s) For Plastic Finisher

What are the key skills required to be a Plastic Finisher?

Key skills include proficiency in plastic molding techniques, knowledge of plastic materials, troubleshooting and problem-solving abilities, attention to detail, and a commitment to quality.

What are the different types of plastic molding processes?

Common plastic molding processes include injection molding, compression molding, blow molding, rotational molding, and thermoforming.

What are the career prospects for Plastic Finishers?

Plastic Finishers can advance to roles such as lead operator, supervisor, or quality control inspector.

What are the safety precautions that Plastic Finishers must follow?

Safety precautions include wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the industry trends that are impacting Plastic Finishers?

Industry trends include the increasing use of automation, the adoption of sustainable materials, and the demand for higher-quality plastic products.

What are the key certifications for Plastic Finishers?

Relevant certifications include the Certified Plastics Technician (CPT) certification offered by the Society of Plastics Engineers (SPE) and the Certified Molding Technician (CMT) certification offered by the American Mold Builders Association (AMBA).