Are you a seasoned Scarfing Machine Operator seeking a new career path? Discover our professionally built Scarfing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

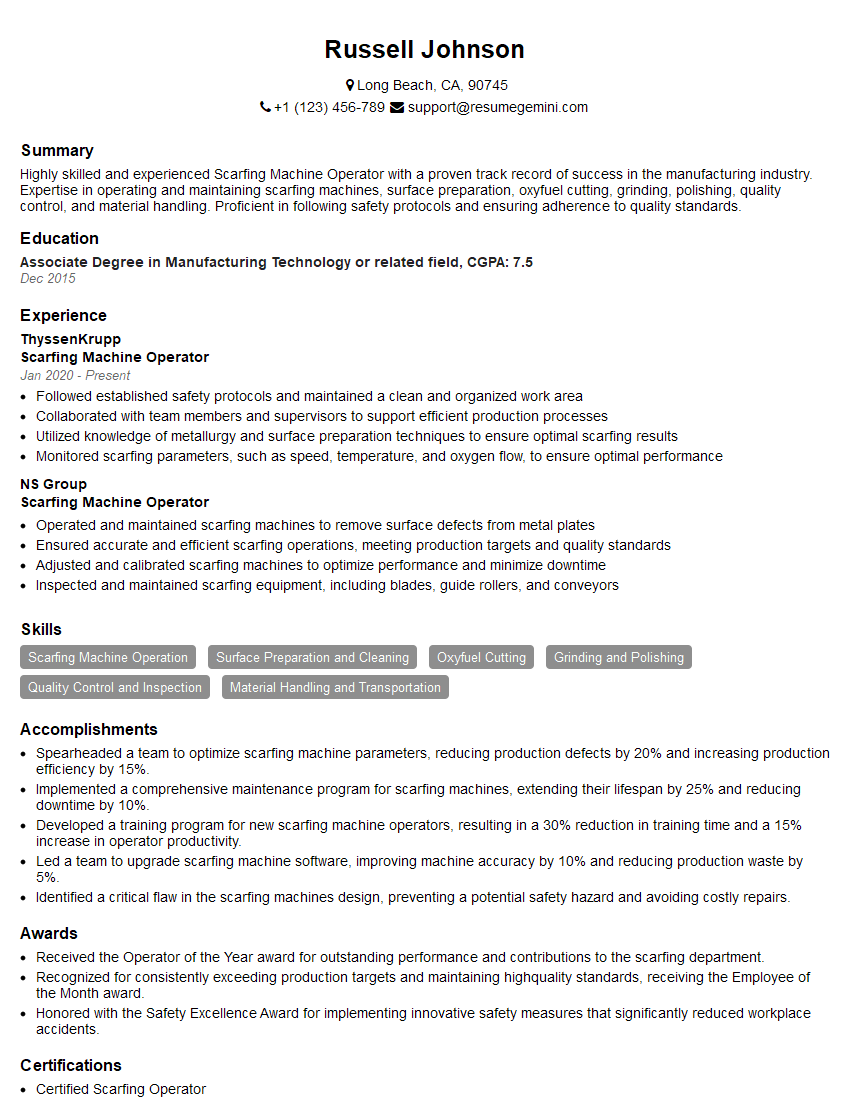

Russell Johnson

Scarfing Machine Operator

Summary

Highly skilled and experienced Scarfing Machine Operator with a proven track record of success in the manufacturing industry. Expertise in operating and maintaining scarfing machines, surface preparation, oxyfuel cutting, grinding, polishing, quality control, and material handling. Proficient in following safety protocols and ensuring adherence to quality standards.

Education

Associate Degree in Manufacturing Technology or related field

December 2015

Skills

- Scarfing Machine Operation

- Surface Preparation and Cleaning

- Oxyfuel Cutting

- Grinding and Polishing

- Quality Control and Inspection

- Material Handling and Transportation

Work Experience

Scarfing Machine Operator

- Followed established safety protocols and maintained a clean and organized work area

- Collaborated with team members and supervisors to support efficient production processes

- Utilized knowledge of metallurgy and surface preparation techniques to ensure optimal scarfing results

- Monitored scarfing parameters, such as speed, temperature, and oxygen flow, to ensure optimal performance

Scarfing Machine Operator

- Operated and maintained scarfing machines to remove surface defects from metal plates

- Ensured accurate and efficient scarfing operations, meeting production targets and quality standards

- Adjusted and calibrated scarfing machines to optimize performance and minimize downtime

- Inspected and maintained scarfing equipment, including blades, guide rollers, and conveyors

Accomplishments

- Spearheaded a team to optimize scarfing machine parameters, reducing production defects by 20% and increasing production efficiency by 15%.

- Implemented a comprehensive maintenance program for scarfing machines, extending their lifespan by 25% and reducing downtime by 10%.

- Developed a training program for new scarfing machine operators, resulting in a 30% reduction in training time and a 15% increase in operator productivity.

- Led a team to upgrade scarfing machine software, improving machine accuracy by 10% and reducing production waste by 5%.

- Identified a critical flaw in the scarfing machines design, preventing a potential safety hazard and avoiding costly repairs.

Awards

- Received the Operator of the Year award for outstanding performance and contributions to the scarfing department.

- Recognized for consistently exceeding production targets and maintaining highquality standards, receiving the Employee of the Month award.

- Honored with the Safety Excellence Award for implementing innovative safety measures that significantly reduced workplace accidents.

Certificates

- Certified Scarfing Operator

- OSHA Safety Certification

- ASME Boiler and Pressure Vessel Code

- AWS Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Scarfing Machine Operator

- Highlight your experience and skills in operating scarfing machines and related equipment

- Quantify your accomplishments using specific metrics to demonstrate your impact

- Showcase your knowledge of quality control procedures and your commitment to meeting standards

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment

Essential Experience Highlights for a Strong Scarfing Machine Operator Resume

- Operate and maintain scarfing machines to remove surface defects and prepare materials for further processing

- Perform surface preparation tasks such as grinding, polishing, and cleaning to ensure proper adhesion and surface finish

- Use oxyfuel cutting techniques to cut and shape materials according to specifications

- Inspect and test materials to ensure they meet quality standards

- Handle and transport materials safely and efficiently

- Maintain a clean and organized work area

- Adhere to safety protocols and follow all established guidelines

Frequently Asked Questions (FAQ’s) For Scarfing Machine Operator

What is a Scarfing Machine Operator?

A Scarfing Machine Operator is responsible for operating and maintaining scarfing machines, which are used to remove surface defects and prepare materials for further processing in the manufacturing industry.

What are the key skills required for a Scarfing Machine Operator?

Key skills for a Scarfing Machine Operator include proficiency in operating and maintaining scarfing machines, surface preparation techniques, oxyfuel cutting, grinding, polishing, quality control, and material handling.

What industries employ Scarfing Machine Operators?

Scarfing Machine Operators are employed in various industries, including steel manufacturing, shipbuilding, and automotive manufacturing.

What is the average salary for a Scarfing Machine Operator?

The average salary for a Scarfing Machine Operator can vary depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $40,000 per year.

What are the career advancement opportunities for a Scarfing Machine Operator?

With experience and additional training, Scarfing Machine Operators can advance to roles such as Quality Control Inspector, Supervisor, or Manufacturing Manager.

What are the safety precautions that Scarfing Machine Operators must follow?

Scarfing Machine Operators must follow strict safety protocols, including wearing appropriate protective gear, operating machines according to guidelines, and adhering to established safety procedures.

What is the job outlook for Scarfing Machine Operators?

The job outlook for Scarfing Machine Operators is expected to be stable in the coming years due to the ongoing demand for skilled manufacturing professionals.

What are the benefits of working as a Scarfing Machine Operator?

Benefits of working as a Scarfing Machine Operator include competitive salary, job stability, opportunities for career advancement, and the satisfaction of working in a skilled trade.