Are you a seasoned Cut-Press Operator seeking a new career path? Discover our professionally built Cut-Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

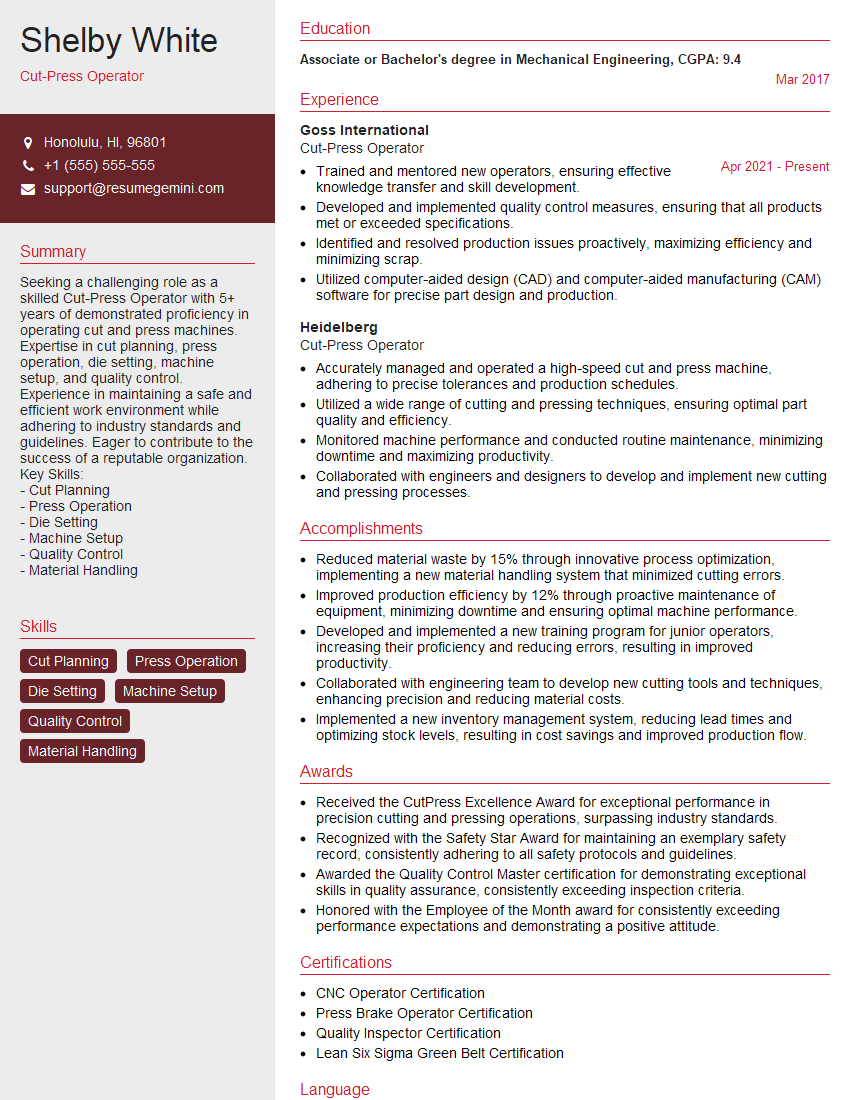

Shelby White

Cut-Press Operator

Summary

Seeking a challenging role as a skilled Cut-Press Operator with 5+ years of demonstrated proficiency in operating cut and press machines. Expertise in cut planning, press operation, die setting, machine setup, and quality control. Experience in maintaining a safe and efficient work environment while adhering to industry standards and guidelines. Eager to contribute to the success of a reputable organization.

Key Skills:

– Cut Planning

– Press Operation

– Die Setting

– Machine Setup

– Quality Control

– Material Handling

Education

Associate or Bachelor’s degree in Mechanical Engineering

March 2017

Skills

- Cut Planning

- Press Operation

- Die Setting

- Machine Setup

- Quality Control

- Material Handling

Work Experience

Cut-Press Operator

- Trained and mentored new operators, ensuring effective knowledge transfer and skill development.

- Developed and implemented quality control measures, ensuring that all products met or exceeded specifications.

- Identified and resolved production issues proactively, maximizing efficiency and minimizing scrap.

- Utilized computer-aided design (CAD) and computer-aided manufacturing (CAM) software for precise part design and production.

Cut-Press Operator

- Accurately managed and operated a high-speed cut and press machine, adhering to precise tolerances and production schedules.

- Utilized a wide range of cutting and pressing techniques, ensuring optimal part quality and efficiency.

- Monitored machine performance and conducted routine maintenance, minimizing downtime and maximizing productivity.

- Collaborated with engineers and designers to develop and implement new cutting and pressing processes.

Accomplishments

- Reduced material waste by 15% through innovative process optimization, implementing a new material handling system that minimized cutting errors.

- Improved production efficiency by 12% through proactive maintenance of equipment, minimizing downtime and ensuring optimal machine performance.

- Developed and implemented a new training program for junior operators, increasing their proficiency and reducing errors, resulting in improved productivity.

- Collaborated with engineering team to develop new cutting tools and techniques, enhancing precision and reducing material costs.

- Implemented a new inventory management system, reducing lead times and optimizing stock levels, resulting in cost savings and improved production flow.

Awards

- Received the CutPress Excellence Award for exceptional performance in precision cutting and pressing operations, surpassing industry standards.

- Recognized with the Safety Star Award for maintaining an exemplary safety record, consistently adhering to all safety protocols and guidelines.

- Awarded the Quality Control Master certification for demonstrating exceptional skills in quality assurance, consistently exceeding inspection criteria.

- Honored with the Employee of the Month award for consistently exceeding performance expectations and demonstrating a positive attitude.

Certificates

- CNC Operator Certification

- Press Brake Operator Certification

- Quality Inspector Certification

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cut-Press Operator

- Highlight your technical proficiency in cut and press operations, including knowledge of machine specifications and industry standards.

- Showcase your experience in quality control and adherence to safety protocols, demonstrating your commitment to delivering high-quality products.

- Emphasize your problem-solving abilities and experience in troubleshooting and resolving machine issues effectively.

- Provide specific examples of your contributions to previous organizations, quantifying your accomplishments whenever possible.

Essential Experience Highlights for a Strong Cut-Press Operator Resume

- Plan and execute cut and press operations efficiently, ensuring optimal material utilization and production output.

- Set up and adjust cut and press machines according to specifications, including die alignment and pressure settings.

- Monitor press operations closely, ensuring smooth functioning and identifying and resolving any issues promptly.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Perform regular maintenance and inspections on cut and press machines, identifying potential issues and taking corrective actions.

- Inspect finished products for defects and adherence to quality standards, ensuring customer satisfaction.

- Work effectively as part of a team, collaborating with colleagues and supervisors to achieve common goals.

Frequently Asked Questions (FAQ’s) For Cut-Press Operator

What are the primary responsibilities of a Cut-Press Operator?

Cut-Press Operators are responsible for setting up, operating, and maintaining cut and press machines to produce various products. They ensure efficient material utilization, monitor machine operations, conduct quality checks, and adhere to safety protocols.

What skills are required to excel as a Cut-Press Operator?

Essential skills for Cut-Press Operators include cut planning, press operation, die setting, machine setup, quality control, and material handling. They should also possess mechanical aptitude, problem-solving abilities, and attention to detail.

What industries employ Cut-Press Operators?

Cut-Press Operators are employed in various industries, including manufacturing, automotive, aerospace, and construction. They work in factories and production facilities, operating machinery to produce metal, plastic, wood, and other materials.

What is the career path for a Cut-Press Operator?

Experienced Cut-Press Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager. They may also specialize in specific areas, such as die making or machine maintenance.

What safety precautions should Cut-Press Operators observe?

Cut-Press Operators must follow strict safety protocols to prevent accidents. They wear protective gear, operate machines with caution, and receive regular training on safety procedures.

What is the work environment of a Cut-Press Operator like?

Cut-Press Operators typically work in factories or production facilities. The environment can be noisy and involve exposure to machinery, moving parts, and chemicals. They may also work in shifts and overtime to meet production demands.

What are the job prospects for Cut-Press Operators?

The job outlook for Cut-Press Operators is expected to remain stable in the coming years. However, automation and technological advancements may impact the demand for these roles.