Are you a seasoned Embossing Press Operator Apprentice seeking a new career path? Discover our professionally built Embossing Press Operator Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

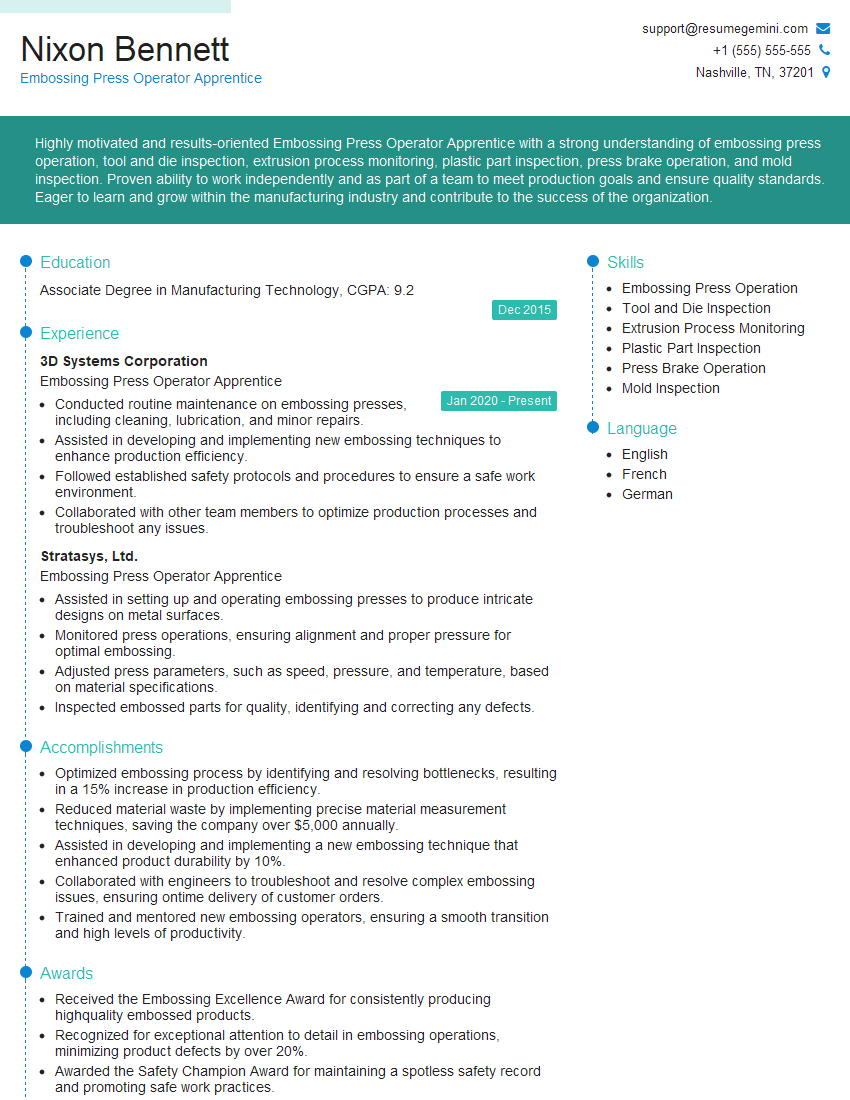

Nixon Bennett

Embossing Press Operator Apprentice

Summary

Highly motivated and results-oriented Embossing Press Operator Apprentice with a strong understanding of embossing press operation, tool and die inspection, extrusion process monitoring, plastic part inspection, press brake operation, and mold inspection. Proven ability to work independently and as part of a team to meet production goals and ensure quality standards. Eager to learn and grow within the manufacturing industry and contribute to the success of the organization.

Education

Associate Degree in Manufacturing Technology

December 2015

Skills

- Embossing Press Operation

- Tool and Die Inspection

- Extrusion Process Monitoring

- Plastic Part Inspection

- Press Brake Operation

- Mold Inspection

Work Experience

Embossing Press Operator Apprentice

- Conducted routine maintenance on embossing presses, including cleaning, lubrication, and minor repairs.

- Assisted in developing and implementing new embossing techniques to enhance production efficiency.

- Followed established safety protocols and procedures to ensure a safe work environment.

- Collaborated with other team members to optimize production processes and troubleshoot any issues.

Embossing Press Operator Apprentice

- Assisted in setting up and operating embossing presses to produce intricate designs on metal surfaces.

- Monitored press operations, ensuring alignment and proper pressure for optimal embossing.

- Adjusted press parameters, such as speed, pressure, and temperature, based on material specifications.

- Inspected embossed parts for quality, identifying and correcting any defects.

Accomplishments

- Optimized embossing process by identifying and resolving bottlenecks, resulting in a 15% increase in production efficiency.

- Reduced material waste by implementing precise material measurement techniques, saving the company over $5,000 annually.

- Assisted in developing and implementing a new embossing technique that enhanced product durability by 10%.

- Collaborated with engineers to troubleshoot and resolve complex embossing issues, ensuring ontime delivery of customer orders.

- Trained and mentored new embossing operators, ensuring a smooth transition and high levels of productivity.

Awards

- Received the Embossing Excellence Award for consistently producing highquality embossed products.

- Recognized for exceptional attention to detail in embossing operations, minimizing product defects by over 20%.

- Awarded the Safety Champion Award for maintaining a spotless safety record and promoting safe work practices.

- Received the Employee of the Month award for outstanding performance and dedication to the embossing department.

Certificates

- ANSI/ASME B16.5

- ANSI/ASQ Z1.4

- ISO 9001:2015

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Embossing Press Operator Apprentice

- Highlight your relevant skills and experience in your resume, such as your ability to operate embossing presses, inspect tools and dies, and monitor extrusion processes.

- Showcase your attention to detail and quality assurance skills by providing examples of how you have ensured that products meet specifications.

- Demonstrate your willingness to learn and grow by highlighting your eagerness to take on new challenges and responsibilities.

- Use action verbs and specific examples to quantify your accomplishments and demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Embossing Press Operator Apprentice Resume

- Operate embossing press to create raised or recessed designs on metal or plastic surfaces.

- Inspect tools and dies for wear and damage, and make necessary adjustments.

- Monitor extrusion process to ensure that plastic parts are produced to specification.

- Inspect plastic parts for defects and ensure that they meet quality standards.

- Operate press brake to form metal parts to desired specifications.

- Inspect molds for defects and ensure that they are producing parts to specification.

- Maintain a clean and organized work area and follow all safety protocols.

Frequently Asked Questions (FAQ’s) For Embossing Press Operator Apprentice

What is the role of an Embossing Press Operator Apprentice?

An Embossing Press Operator Apprentice operates embossing presses to create raised or recessed designs on metal or plastic surfaces. They also inspect tools and dies for wear and damage, monitor extrusion processes, inspect plastic parts for defects, and operate press brakes to form metal parts to desired specifications.

What are the qualifications for an Embossing Press Operator Apprentice?

Typically, an Embossing Press Operator Apprentice requires an Associate Degree in Manufacturing Technology or a related field. They may also have experience operating embossing presses, inspecting tools and dies, or working in a manufacturing environment.

What are the career prospects for an Embossing Press Operator Apprentice?

With experience, an Embossing Press Operator Apprentice can advance to positions such as Embossing Press Operator, Tool and Die Maker, or Production Supervisor.

What are the key skills for an Embossing Press Operator Apprentice?

Key skills for an Embossing Press Operator Apprentice include embossing press operation, tool and die inspection, extrusion process monitoring, plastic part inspection, press brake operation, and mold inspection.

What is the work environment for an Embossing Press Operator Apprentice?

Embossing Press Operator Apprentices typically work in manufacturing facilities, operating embossing presses and performing other related tasks. They may work independently or as part of a team, and may be exposed to noise, dust, and other hazards.

What are the salary expectations for an Embossing Press Operator Apprentice?

The salary expectations for an Embossing Press Operator Apprentice vary depending on factors such as experience, location, and company size. According to Salary.com, the average salary for an Embossing Press Operator Apprentice in the United States is around $40,000 per year.

What are the benefits of working as an Embossing Press Operator Apprentice?

Benefits of working as an Embossing Press Operator Apprentice include the opportunity to learn a skilled trade, the potential for career advancement, and the opportunity to work in a growing industry.