Are you a seasoned Lithograph Press Operator seeking a new career path? Discover our professionally built Lithograph Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

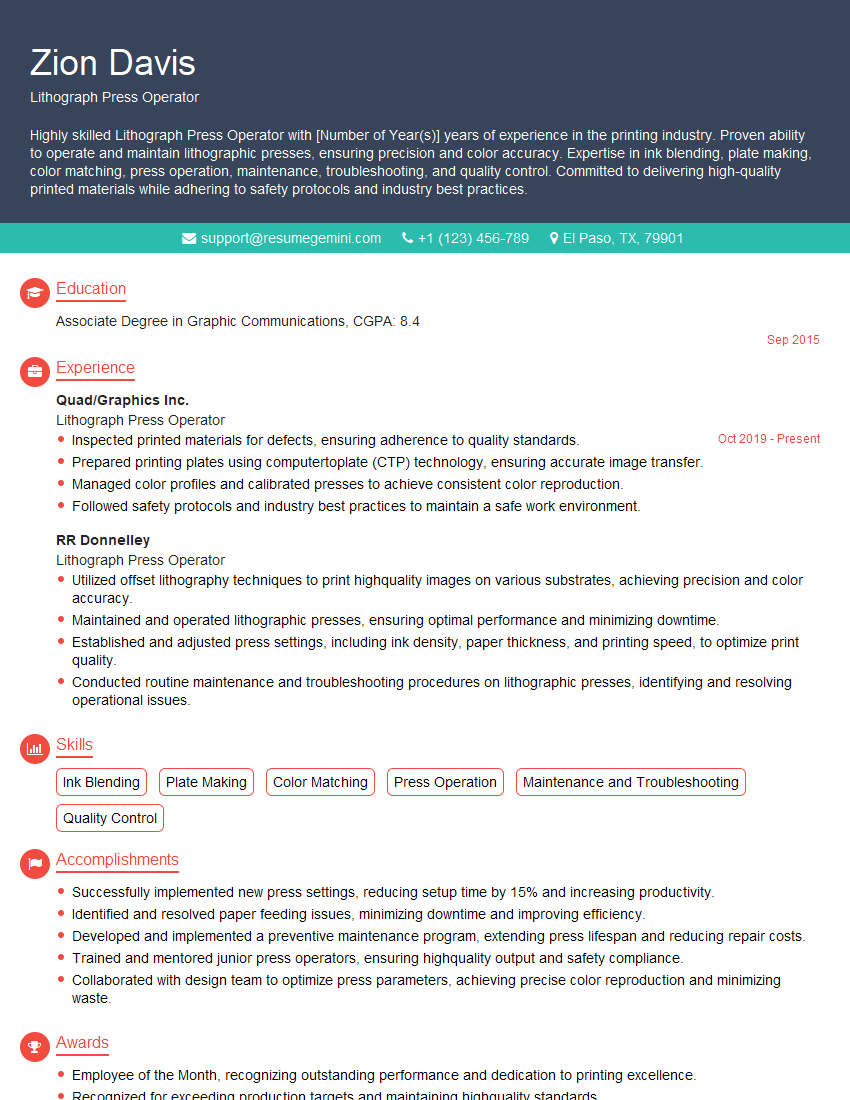

Zion Davis

Lithograph Press Operator

Summary

Highly skilled Lithograph Press Operator with [Number of Year(s)] years of experience in the printing industry. Proven ability to operate and maintain lithographic presses, ensuring precision and color accuracy. Expertise in ink blending, plate making, color matching, press operation, maintenance, troubleshooting, and quality control. Committed to delivering high-quality printed materials while adhering to safety protocols and industry best practices.

Education

Associate Degree in Graphic Communications

September 2015

Skills

- Ink Blending

- Plate Making

- Color Matching

- Press Operation

- Maintenance and Troubleshooting

- Quality Control

Work Experience

Lithograph Press Operator

- Inspected printed materials for defects, ensuring adherence to quality standards.

- Prepared printing plates using computertoplate (CTP) technology, ensuring accurate image transfer.

- Managed color profiles and calibrated presses to achieve consistent color reproduction.

- Followed safety protocols and industry best practices to maintain a safe work environment.

Lithograph Press Operator

- Utilized offset lithography techniques to print highquality images on various substrates, achieving precision and color accuracy.

- Maintained and operated lithographic presses, ensuring optimal performance and minimizing downtime.

- Established and adjusted press settings, including ink density, paper thickness, and printing speed, to optimize print quality.

- Conducted routine maintenance and troubleshooting procedures on lithographic presses, identifying and resolving operational issues.

Accomplishments

- Successfully implemented new press settings, reducing setup time by 15% and increasing productivity.

- Identified and resolved paper feeding issues, minimizing downtime and improving efficiency.

- Developed and implemented a preventive maintenance program, extending press lifespan and reducing repair costs.

- Trained and mentored junior press operators, ensuring highquality output and safety compliance.

- Collaborated with design team to optimize press parameters, achieving precise color reproduction and minimizing waste.

Awards

- Employee of the Month, recognizing outstanding performance and dedication to printing excellence.

- Recognized for exceeding production targets and maintaining highquality standards.

Certificates

- Printing Industry of America (PIA) Press Operator Certification

- National Association of Printing Ink Manufacturers (NAPIM) Ink Mixing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lithograph Press Operator

- Highlight your proficiency in offset lithography techniques and demonstrate your understanding of the printing process.

- Quantify your accomplishments whenever possible, using specific metrics to showcase your impact.

- Emphasize your attention to detail and commitment to quality.

- Include relevant certifications or training programs that demonstrate your expertise in lithographic press operation.

- Tailor your resume specifically to the job description, highlighting skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Lithograph Press Operator Resume

- Utilized offset lithography techniques to print high-quality images on various substrates, achieving precision and color accuracy.

- Maintained and operated lithographic presses, ensuring optimal performance and minimizing downtime.

- Established and adjusted press settings, including ink density, paper thickness, and printing speed, to optimize print quality.

- Conducted routine maintenance and troubleshooting procedures on lithographic presses, identifying and resolving operational issues.

- Inspected printed materials for defects, ensuring adherence to quality standards.

- Prepared printing plates using computer-to-plate (CTP) technology, ensuring accurate image transfer.

- Managed color profiles and calibrated presses to achieve consistent color reproduction.

Frequently Asked Questions (FAQ’s) For Lithograph Press Operator

What are the essential skills required for a Lithograph Press Operator?

Essential skills include proficiency in offset lithography techniques, press operation, maintenance and troubleshooting, ink blending, plate making, color matching, and quality control.

What is the primary role of a Lithograph Press Operator?

The primary role is to operate and maintain lithographic presses, ensuring high-quality printed materials while adhering to safety protocols and industry best practices.

What is the work environment like for a Lithograph Press Operator?

The work environment typically involves working in a printing facility with potential exposure to noise, ink fumes, and hazardous chemicals. Safety precautions and proper ventilation systems are essential.

Are there opportunities for career advancement as a Lithograph Press Operator?

Yes, career advancement opportunities may include supervisory roles, technical support positions, or management positions within the printing industry.

What is the earning potential for a Lithograph Press Operator?

Earning potential varies depending on experience, location, and company size. According to Indeed, the average annual salary for a Lithograph Press Operator in the United States is approximately $55,000.

What are the safety protocols that Lithograph Press Operators must follow?

Safety protocols include wearing appropriate protective gear, following lockout/tagout procedures, adhering to chemical handling guidelines, and maintaining a clean and organized work area.

What are some tips for succeeding as a Lithograph Press Operator?

Tips for succeeding include staying up-to-date on industry best practices, seeking opportunities for professional development, maintaining a strong attention to detail, and fostering?????????????