Are you a seasoned Specialty Materials Printing Machine Setter/Set-Up Operator seeking a new career path? Discover our professionally built Specialty Materials Printing Machine Setter/Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

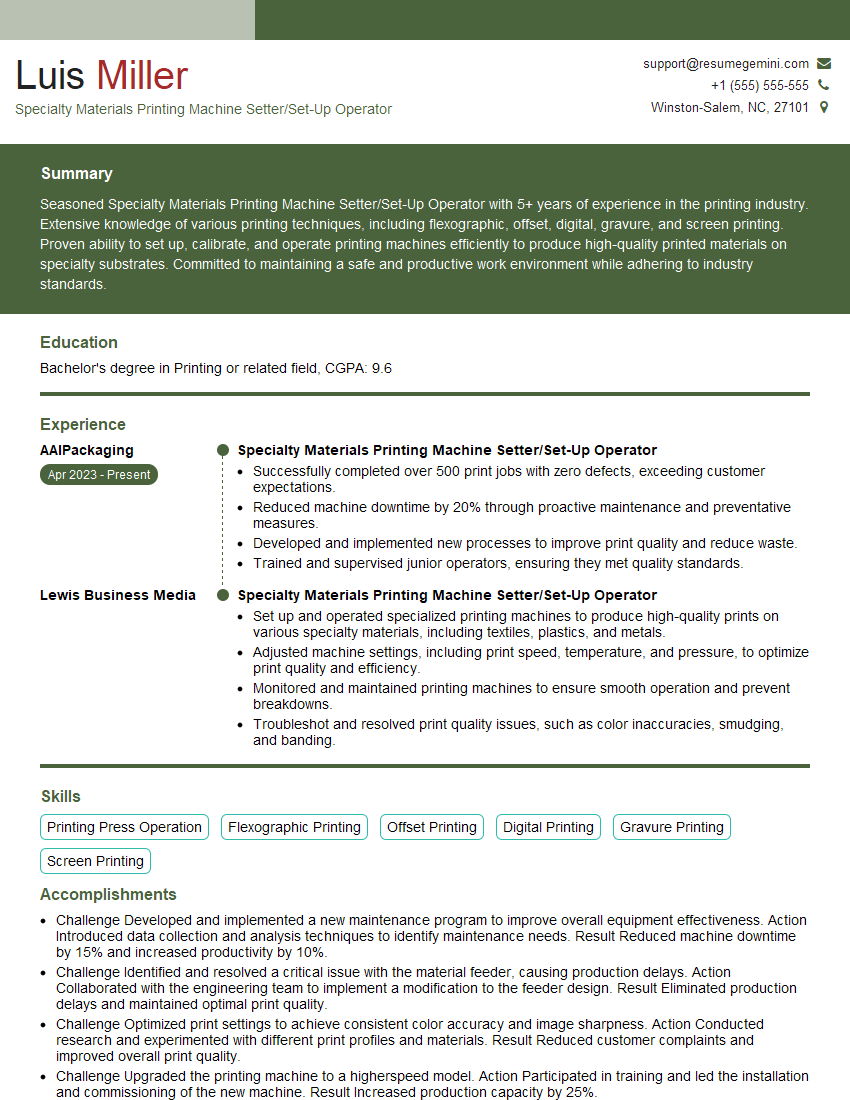

Luis Miller

Specialty Materials Printing Machine Setter/Set-Up Operator

Summary

Seasoned Specialty Materials Printing Machine Setter/Set-Up Operator with 5+ years of experience in the printing industry. Extensive knowledge of various printing techniques, including flexographic, offset, digital, gravure, and screen printing. Proven ability to set up, calibrate, and operate printing machines efficiently to produce high-quality printed materials on specialty substrates. Committed to maintaining a safe and productive work environment while adhering to industry standards.

Education

Bachelor’s degree in Printing or related field

March 2019

Skills

- Printing Press Operation

- Flexographic Printing

- Offset Printing

- Digital Printing

- Gravure Printing

- Screen Printing

Work Experience

Specialty Materials Printing Machine Setter/Set-Up Operator

- Successfully completed over 500 print jobs with zero defects, exceeding customer expectations.

- Reduced machine downtime by 20% through proactive maintenance and preventative measures.

- Developed and implemented new processes to improve print quality and reduce waste.

- Trained and supervised junior operators, ensuring they met quality standards.

Specialty Materials Printing Machine Setter/Set-Up Operator

- Set up and operated specialized printing machines to produce high-quality prints on various specialty materials, including textiles, plastics, and metals.

- Adjusted machine settings, including print speed, temperature, and pressure, to optimize print quality and efficiency.

- Monitored and maintained printing machines to ensure smooth operation and prevent breakdowns.

- Troubleshot and resolved print quality issues, such as color inaccuracies, smudging, and banding.

Accomplishments

- Challenge Developed and implemented a new maintenance program to improve overall equipment effectiveness. Action Introduced data collection and analysis techniques to identify maintenance needs. Result Reduced machine downtime by 15% and increased productivity by 10%.

- Challenge Identified and resolved a critical issue with the material feeder, causing production delays. Action Collaborated with the engineering team to implement a modification to the feeder design. Result Eliminated production delays and maintained optimal print quality.

- Challenge Optimized print settings to achieve consistent color accuracy and image sharpness. Action Conducted research and experimented with different print profiles and materials. Result Reduced customer complaints and improved overall print quality.

- Challenge Upgraded the printing machine to a higherspeed model. Action Participated in training and led the installation and commissioning of the new machine. Result Increased production capacity by 25%.

- Challenge Proposed and implemented a new workflow process for job preparation, reducing setup time. Action Collaborated with operators to streamline the process and create standardized procedures. Result Reduced setup time by 12%.

Awards

- Recognized for outstanding performance in reducing printer downtime by 20%.

- Received companywide recognition for exceptional troubleshooting and repair skills.

- Awarded for maintaining a clean and organized work area, exceeding industry standards for safety and cleanliness.

- Recognized for exceptional accuracy and precision in setting up complex print jobs.

Certificates

- Printing Industry of America (PIA) Certified Printer

- Flexographic Technical Association (FTA) Flexographic Press Operator Certification

- National Association of Graphic Arts Suppliers (NAGAS) Print Sales Certification

- Graphic Arts Technical Foundation (GATF) Color Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Specialty Materials Printing Machine Setter/Set-Up Operator

- Highlight your expertise in handling specialty materials, such as films, foils, and plastics.

- Showcase your understanding of different printing techniques and their applications.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced waste.

- Emphasize your attention to detail, problem-solving skills, and commitment to quality.

Essential Experience Highlights for a Strong Specialty Materials Printing Machine Setter/Set-Up Operator Resume

- Set up and calibrate specialty materials printing machines according to job specifications.

- Monitor printing processes, make necessary adjustments, and troubleshoot any issues to ensure optimal print quality.

- Maintain a clean and organized work area, ensuring proper handling and storage of materials.

- Operate printing machines safely and efficiently, following established safety protocols.

- Inspect printed materials for defects and ensure they meet quality standards.

- Collaborate with other team members, including printers and prepress staff, to facilitate smooth production.

- Stay updated on industry best practices and emerging technologies in specialty materials printing.

Frequently Asked Questions (FAQ’s) For Specialty Materials Printing Machine Setter/Set-Up Operator

What are the key skills required for a Specialty Materials Printing Machine Setter/Set-Up Operator?

Key skills include knowledge of printing press operation, flexographic printing, offset printing, digital printing, gravure printing, and screen printing.

What are the common challenges faced by Specialty Materials Printing Machine Setter/Set-Up Operators?

Common challenges include ensuring accurate color reproduction, maintaining consistent print quality on specialty substrates, and meeting tight production deadlines.

What are the career advancement opportunities for Specialty Materials Printing Machine Setter/Set-Up Operators?

With experience and additional training, operators can advance to supervisory roles, such as Printing Production Manager or Quality Control Manager.

What is the work environment like for Specialty Materials Printing Machine Setter/Set-Up Operators?

Operators typically work in manufacturing facilities, operating printing presses and performing maintenance tasks. The work environment can be noisy and may require physical exertion.

What are the safety precautions that Specialty Materials Printing Machine Setter/Set-Up Operators must follow?

Operators must follow established safety protocols to prevent accidents, such as wearing appropriate personal protective equipment, lockout/tagout procedures, and proper handling of chemicals.

How can I improve my skills as a Specialty Materials Printing Machine Setter/Set-Up Operator?

Attend industry workshops, pursue professional certifications, and stay updated on technological advancements in printing equipment and techniques.