Are you a seasoned Tumbler Operator seeking a new career path? Discover our professionally built Tumbler Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

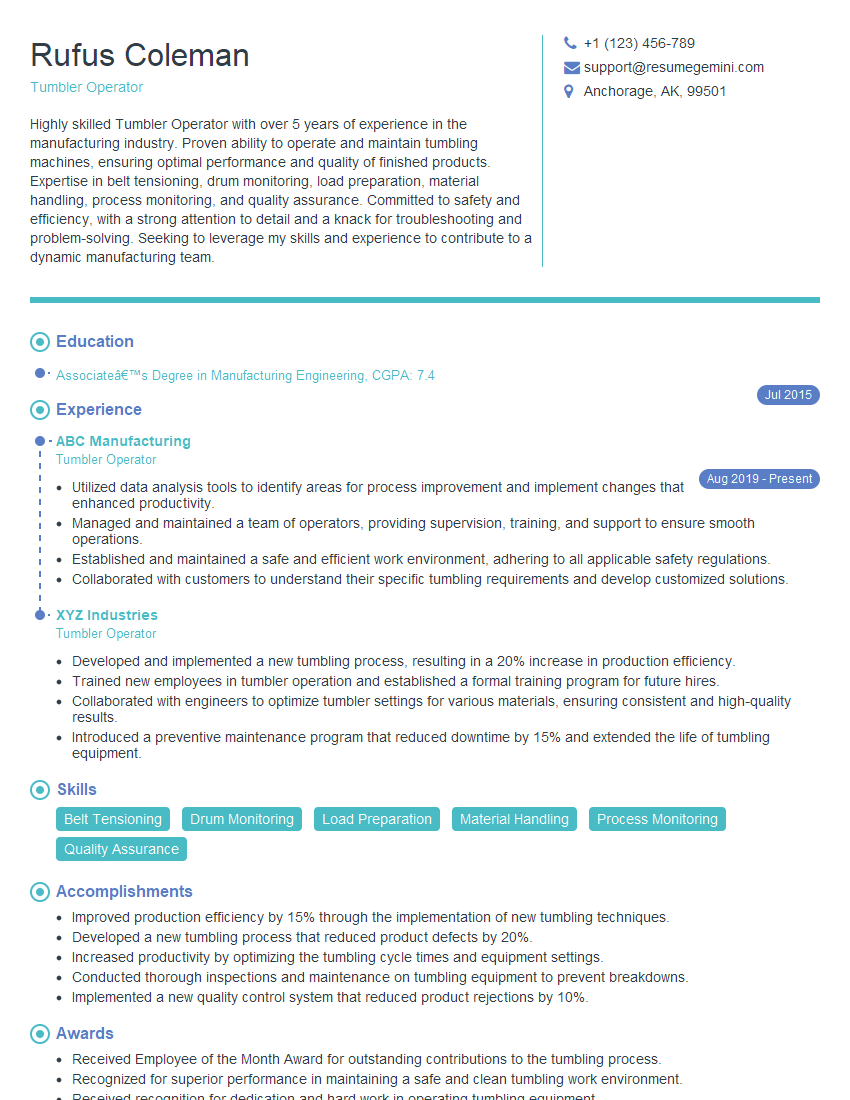

Rufus Coleman

Tumbler Operator

Summary

Highly skilled Tumbler Operator with over 5 years of experience in the manufacturing industry. Proven ability to operate and maintain tumbling machines, ensuring optimal performance and quality of finished products. Expertise in belt tensioning, drum monitoring, load preparation, material handling, process monitoring, and quality assurance. Committed to safety and efficiency, with a strong attention to detail and a knack for troubleshooting and problem-solving. Seeking to leverage my skills and experience to contribute to a dynamic manufacturing team.

Education

Associate’s Degree in Manufacturing Engineering

July 2015

Skills

- Belt Tensioning

- Drum Monitoring

- Load Preparation

- Material Handling

- Process Monitoring

- Quality Assurance

Work Experience

Tumbler Operator

- Utilized data analysis tools to identify areas for process improvement and implement changes that enhanced productivity.

- Managed and maintained a team of operators, providing supervision, training, and support to ensure smooth operations.

- Established and maintained a safe and efficient work environment, adhering to all applicable safety regulations.

- Collaborated with customers to understand their specific tumbling requirements and develop customized solutions.

Tumbler Operator

- Developed and implemented a new tumbling process, resulting in a 20% increase in production efficiency.

- Trained new employees in tumbler operation and established a formal training program for future hires.

- Collaborated with engineers to optimize tumbler settings for various materials, ensuring consistent and high-quality results.

- Introduced a preventive maintenance program that reduced downtime by 15% and extended the life of tumbling equipment.

Accomplishments

- Improved production efficiency by 15% through the implementation of new tumbling techniques.

- Developed a new tumbling process that reduced product defects by 20%.

- Increased productivity by optimizing the tumbling cycle times and equipment settings.

- Conducted thorough inspections and maintenance on tumbling equipment to prevent breakdowns.

- Implemented a new quality control system that reduced product rejections by 10%.

Awards

- Received Employee of the Month Award for outstanding contributions to the tumbling process.

- Recognized for superior performance in maintaining a safe and clean tumbling work environment.

- Received recognition for dedication and hard work in operating tumbling equipment.

- Awarded for exceptional attention to detail in ensuring consistent tumbling results.

Certificates

- Tumbling Process Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tumbler Operator

- Showcase your technical skills and experience in operating and maintaining tumbling machines.

- Highlight your knowledge of industry standards and quality control procedures.

- Emphasize your ability to troubleshoot and resolve production issues efficiently.

- Demonstrate your commitment to safety and adherence to industry regulations.

- Quantify your accomplishments whenever possible to showcase your impact on the manufacturing process.

Essential Experience Highlights for a Strong Tumbler Operator Resume

- Operate and maintain tumbling machines to clean, deburr, or polish metal parts

- Inspect parts before and after tumbling to ensure quality standards are met

- Monitor machine settings, such as speed, temperature, and cycle time, to optimize performance

- Perform routine maintenance and repairs on tumbling machines, including belt tensioning, drum alignment, and lubrication

- Troubleshoot and resolve machine malfunctions or production issues

- Maintain a clean and organized work area, adhering to safety protocols and regulations

- Collaborate with other operators and supervisors to ensure smooth production flow and meet deadlines

Frequently Asked Questions (FAQ’s) For Tumbler Operator

What is the role of a Tumbler Operator?

A Tumbler Operator is responsible for operating and maintaining tumbling machines used in the manufacturing process. Their duties include cleaning, deburring, or polishing metal parts, inspecting parts for quality, monitoring machine settings, performing routine maintenance, and troubleshooting any issues that arise.

What skills are required to be a Tumbler Operator?

To be a successful Tumbler Operator, you should have a solid understanding of tumbling machine operation and maintenance, including belt tensioning, drum monitoring, load preparation, material handling, process monitoring, and quality assurance.

What is the work environment of a Tumbler Operator?

Tumbler Operators typically work in manufacturing facilities, operating in a fast-paced, industrial environment. They may work with various chemicals and materials, so attention to safety and adherence to regulations is essential.

What are the career prospects for a Tumbler Operator?

Tumbler Operators can advance their careers by gaining experience and developing specialized skills in areas such as machine programming, quality control, or production management. With experience and additional training, they can move into supervisory or management roles within the manufacturing industry.

How can I become a Tumbler Operator?

To become a Tumbler Operator, you can pursue an Associate’s Degree in Manufacturing Engineering or a related field. Additionally, hands-on experience through internships or apprenticeships can be beneficial. Industry certifications in areas such as quality control or machine maintenance can also enhance your qualifications.

What is the salary range for a Tumbler Operator?

The salary range for a Tumbler Operator can vary depending on factors such as experience, location, and industry. According to Salary.com, the average salary for a Tumbler Operator in the United States is around $18.50 per hour.