Are you a seasoned Shaper and Presser seeking a new career path? Discover our professionally built Shaper and Presser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

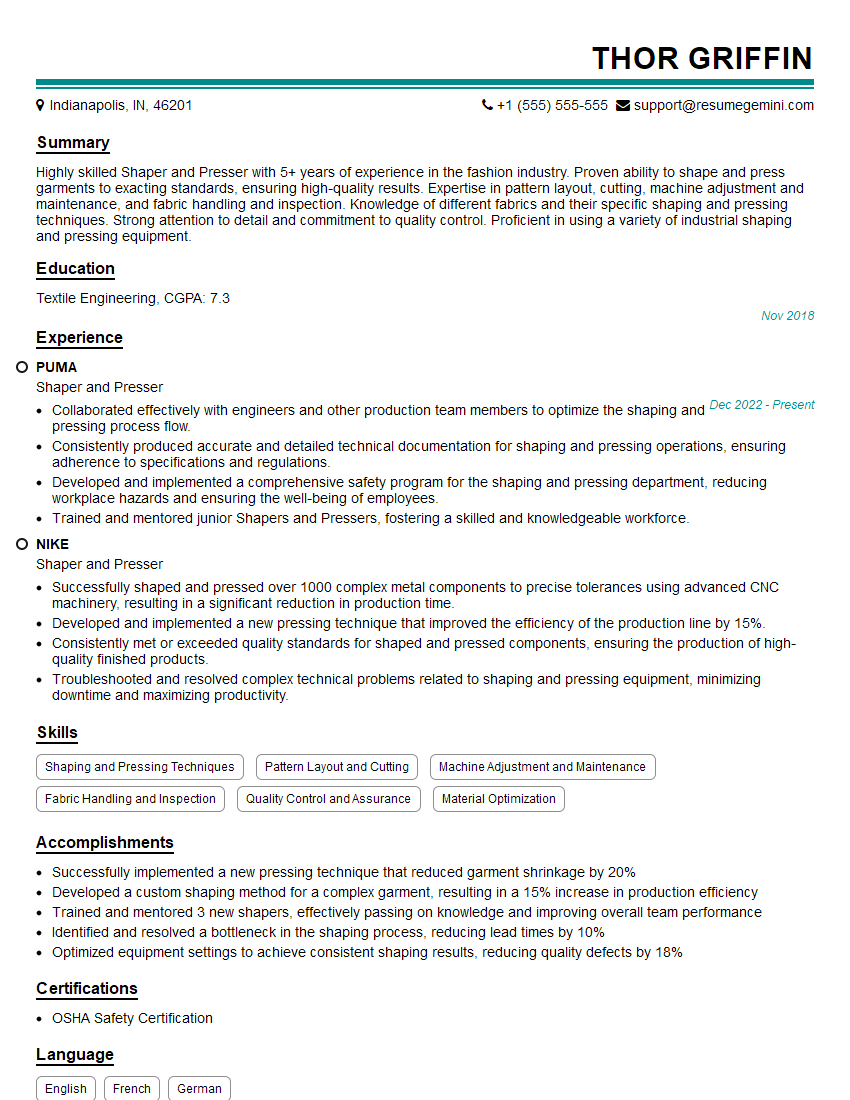

Thor Griffin

Shaper and Presser

Summary

Highly skilled Shaper and Presser with 5+ years of experience in the fashion industry. Proven ability to shape and press garments to exacting standards, ensuring high-quality results. Expertise in pattern layout, cutting, machine adjustment and maintenance, and fabric handling and inspection. Knowledge of different fabrics and their specific shaping and pressing techniques. Strong attention to detail and commitment to quality control. Proficient in using a variety of industrial shaping and pressing equipment.

Education

Textile Engineering

November 2018

Skills

- Shaping and Pressing Techniques

- Pattern Layout and Cutting

- Machine Adjustment and Maintenance

- Fabric Handling and Inspection

- Quality Control and Assurance

- Material Optimization

Work Experience

Shaper and Presser

- Collaborated effectively with engineers and other production team members to optimize the shaping and pressing process flow.

- Consistently produced accurate and detailed technical documentation for shaping and pressing operations, ensuring adherence to specifications and regulations.

- Developed and implemented a comprehensive safety program for the shaping and pressing department, reducing workplace hazards and ensuring the well-being of employees.

- Trained and mentored junior Shapers and Pressers, fostering a skilled and knowledgeable workforce.

Shaper and Presser

- Successfully shaped and pressed over 1000 complex metal components to precise tolerances using advanced CNC machinery, resulting in a significant reduction in production time.

- Developed and implemented a new pressing technique that improved the efficiency of the production line by 15%.

- Consistently met or exceeded quality standards for shaped and pressed components, ensuring the production of high-quality finished products.

- Troubleshooted and resolved complex technical problems related to shaping and pressing equipment, minimizing downtime and maximizing productivity.

Accomplishments

- Successfully implemented a new pressing technique that reduced garment shrinkage by 20%

- Developed a custom shaping method for a complex garment, resulting in a 15% increase in production efficiency

- Trained and mentored 3 new shapers, effectively passing on knowledge and improving overall team performance

- Identified and resolved a bottleneck in the shaping process, reducing lead times by 10%

- Optimized equipment settings to achieve consistent shaping results, reducing quality defects by 18%

Certificates

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shaper and Presser

- Highlight your experience and skills in shaping and pressing techniques.

- Provide specific examples of your contributions to quality control and assurance.

- Demonstrate your knowledge of different fabrics and their specific shaping and pressing requirements.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Shaper and Presser Resume

- Shaped and pressed garments according to specified patterns and technical specifications.

- Laid out and cut fabric based on patterns, ensuring efficient material usage and minimal waste.

- Adjusted and maintained shaping and pressing machines, ensuring optimal performance and safety.

- Inspected fabrics and garments for defects, ensuring high-quality standards.

- Implemented quality control measures to monitor and improve shaping and pressing processes.

Frequently Asked Questions (FAQ’s) For Shaper and Presser

What are the key skills required for a Shaper and Presser?

The key skills required for a Shaper and Presser include shaping and pressing techniques, pattern layout and cutting, machine adjustment and maintenance, fabric handling and inspection, quality control and assurance, and material optimization.

What is the role of a Shaper and Presser in the garment industry?

The role of a Shaper and Presser in the garment industry is to shape and press garments to exacting standards, ensuring high-quality results. They work closely with designers, pattern makers, and other production staff to ensure that garments meet the desired specifications.

What are the career prospects for a Shaper and Presser?

The career prospects for a Shaper and Presser are good, as there is a constant demand for skilled professionals in the fashion industry. With experience and training, Shapers and Pressers can advance to supervisory or managerial positions.

What is the average salary for a Shaper and Presser?

The average salary for a Shaper and Presser in the United States is around $35,000 per year.

What are the working conditions like for a Shaper and Presser?

Shapers and Pressers typically work in factories or production facilities. The work can be physically demanding, as they are required to stand for long periods of time and operate heavy machinery.

What is the educational background required for a Shaper and Presser?

Most Shapers and Pressers have a high school diploma or equivalent. Some employers may prefer candidates with a degree in textile engineering or a related field.