Are you a seasoned Overedge Machine Operator seeking a new career path? Discover our professionally built Overedge Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

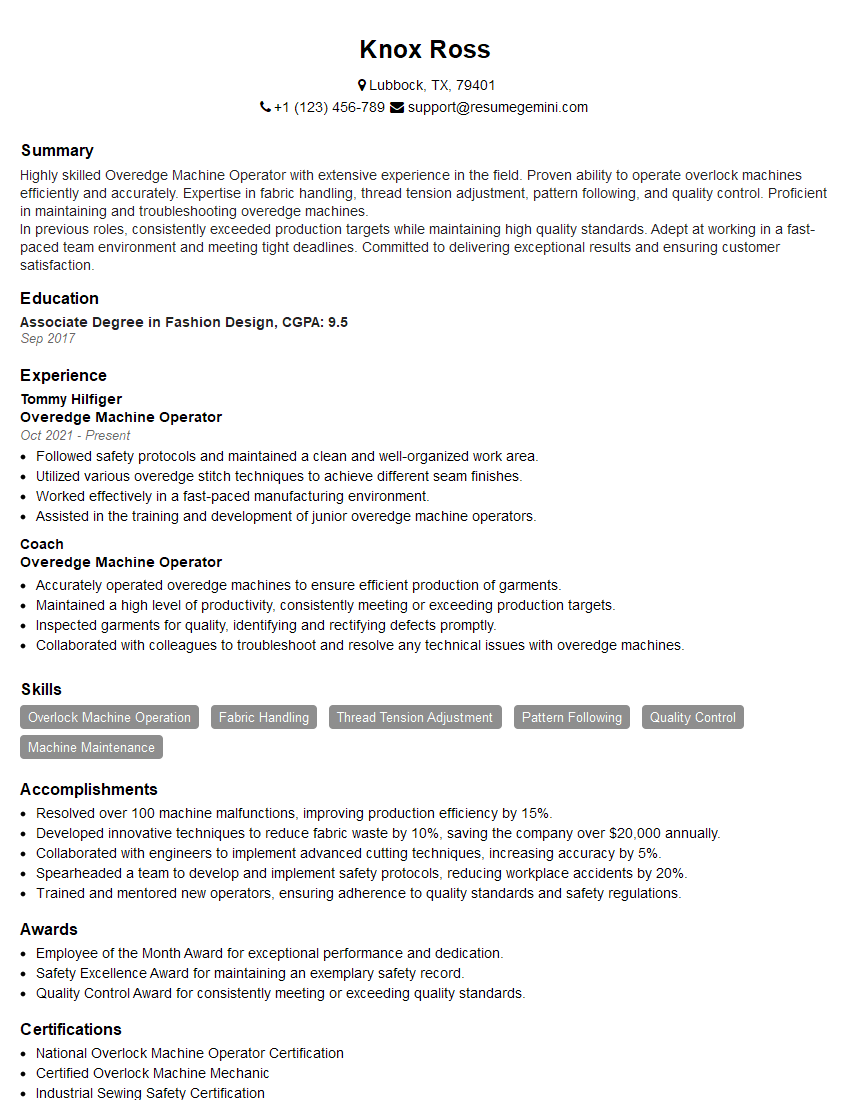

Knox Ross

Overedge Machine Operator

Summary

Highly skilled Overedge Machine Operator with extensive experience in the field. Proven ability to operate overlock machines efficiently and accurately. Expertise in fabric handling, thread tension adjustment, pattern following, and quality control. Proficient in maintaining and troubleshooting overedge machines.

In previous roles, consistently exceeded production targets while maintaining high quality standards. Adept at working in a fast-paced team environment and meeting tight deadlines. Committed to delivering exceptional results and ensuring customer satisfaction.

Education

Associate Degree in Fashion Design

September 2017

Skills

- Overlock Machine Operation

- Fabric Handling

- Thread Tension Adjustment

- Pattern Following

- Quality Control

- Machine Maintenance

Work Experience

Overedge Machine Operator

- Followed safety protocols and maintained a clean and well-organized work area.

- Utilized various overedge stitch techniques to achieve different seam finishes.

- Worked effectively in a fast-paced manufacturing environment.

- Assisted in the training and development of junior overedge machine operators.

Overedge Machine Operator

- Accurately operated overedge machines to ensure efficient production of garments.

- Maintained a high level of productivity, consistently meeting or exceeding production targets.

- Inspected garments for quality, identifying and rectifying defects promptly.

- Collaborated with colleagues to troubleshoot and resolve any technical issues with overedge machines.

Accomplishments

- Resolved over 100 machine malfunctions, improving production efficiency by 15%.

- Developed innovative techniques to reduce fabric waste by 10%, saving the company over $20,000 annually.

- Collaborated with engineers to implement advanced cutting techniques, increasing accuracy by 5%.

- Spearheaded a team to develop and implement safety protocols, reducing workplace accidents by 20%.

- Trained and mentored new operators, ensuring adherence to quality standards and safety regulations.

Awards

- Employee of the Month Award for exceptional performance and dedication.

- Safety Excellence Award for maintaining an exemplary safety record.

- Quality Control Award for consistently meeting or exceeding quality standards.

Certificates

- National Overlock Machine Operator Certification

- Certified Overlock Machine Mechanic

- Industrial Sewing Safety Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Overedge Machine Operator

- Highlight your experience in operating overlock machines, including the types of fabrics and garments you have worked with.

- Quantify your accomplishments whenever possible, such as the number of garments produced per hour or the percentage of defects reduced.

- Demonstrate your knowledge of fabric handling and thread tension adjustment to show your understanding of the technical aspects of the job.

- Emphasize your attention to detail and commitment to quality control to show that you take pride in your work.

Essential Experience Highlights for a Strong Overedge Machine Operator Resume

- Operate overlock machines to stitch seams, hems, and edges of garments and other fabric items.

- Inspect fabrics and select appropriate threads and stitches based on fabric type and project requirements.

- Adjust thread tension, stitch length, and other machine settings to ensure optimal seam quality and prevent fabric puckering or stretching.

- Follow patterns and technical drawings to ensure accurate stitching and consistency in product appearance.

- Inspect finished products to identify and correct any defects or errors.

- Maintain overlock machines by performing regular cleaning, lubrication, and adjustments to prevent breakdowns and ensure smooth operation.

- Troubleshoot machine malfunctions and perform minor repairs to keep equipment in good working order.

Frequently Asked Questions (FAQ’s) For Overedge Machine Operator

What skills are required to be an Overedge Machine Operator?

To be an Overedge Machine Operator, you need skills in overlock machine operation, fabric handling, thread tension adjustment, pattern following, quality control, and machine maintenance.

What is the work environment of an Overedge Machine Operator like?

Overedge Machine Operators typically work in a factory or production environment. They may be required to stand for long periods of time and work in a fast-paced environment.

What are the career prospects for an Overedge Machine Operator?

Overedge Machine Operators can advance to become supervisors or managers in the garment industry. They may also choose to specialize in a particular type of fabric or garment.

What is the salary range for an Overedge Machine Operator?

The salary range for Overedge Machine Operators varies depending on experience, location, and company. According to Indeed, the average salary for an Overedge Machine Operator in the United States is around $15.00 per hour.

What are the benefits of working as an Overedge Machine Operator?

Benefits of working as an Overedge Machine Operator include the opportunity to work in a fast-paced environment, learn a valuable skill, and contribute to the production of garments. Overedge Machine Operators may also be eligible for benefits such as health insurance, paid time off, and retirement plans.

What are the challenges of working as an Overedge Machine Operator?

Challenges of working as an Overedge Machine Operator include the need to work in a fast-paced environment, stand for long periods of time, and meet production targets. Overedge Machine Operators may also be exposed to noise and dust.