Are you a seasoned Loom Operator seeking a new career path? Discover our professionally built Loom Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

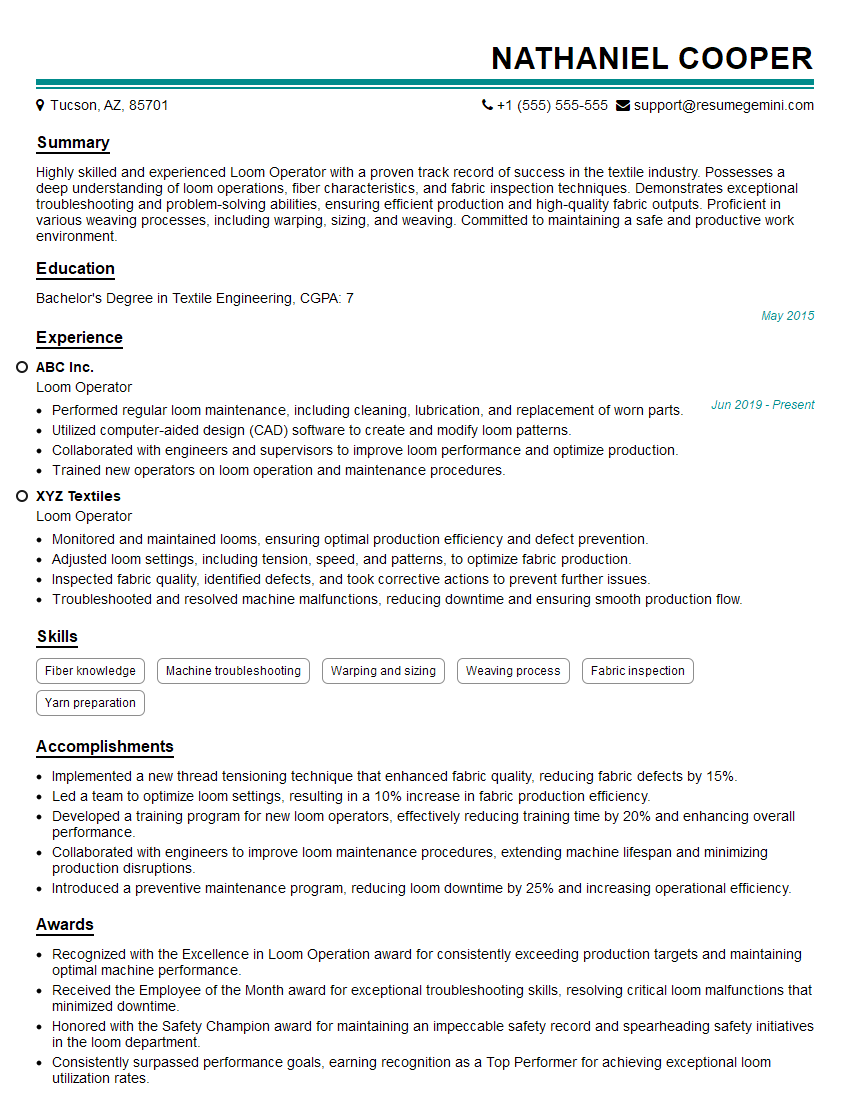

Nathaniel Cooper

Loom Operator

Summary

Highly skilled and experienced Loom Operator with a proven track record of success in the textile industry. Possesses a deep understanding of loom operations, fiber characteristics, and fabric inspection techniques. Demonstrates exceptional troubleshooting and problem-solving abilities, ensuring efficient production and high-quality fabric outputs. Proficient in various weaving processes, including warping, sizing, and weaving. Committed to maintaining a safe and productive work environment.

Education

Bachelor’s Degree in Textile Engineering

May 2015

Skills

- Fiber knowledge

- Machine troubleshooting

- Warping and sizing

- Weaving process

- Fabric inspection

- Yarn preparation

Work Experience

Loom Operator

- Performed regular loom maintenance, including cleaning, lubrication, and replacement of worn parts.

- Utilized computer-aided design (CAD) software to create and modify loom patterns.

- Collaborated with engineers and supervisors to improve loom performance and optimize production.

- Trained new operators on loom operation and maintenance procedures.

Loom Operator

- Monitored and maintained looms, ensuring optimal production efficiency and defect prevention.

- Adjusted loom settings, including tension, speed, and patterns, to optimize fabric production.

- Inspected fabric quality, identified defects, and took corrective actions to prevent further issues.

- Troubleshooted and resolved machine malfunctions, reducing downtime and ensuring smooth production flow.

Accomplishments

- Implemented a new thread tensioning technique that enhanced fabric quality, reducing fabric defects by 15%.

- Led a team to optimize loom settings, resulting in a 10% increase in fabric production efficiency.

- Developed a training program for new loom operators, effectively reducing training time by 20% and enhancing overall performance.

- Collaborated with engineers to improve loom maintenance procedures, extending machine lifespan and minimizing production disruptions.

- Introduced a preventive maintenance program, reducing loom downtime by 25% and increasing operational efficiency.

Awards

- Recognized with the Excellence in Loom Operation award for consistently exceeding production targets and maintaining optimal machine performance.

- Received the Employee of the Month award for exceptional troubleshooting skills, resolving critical loom malfunctions that minimized downtime.

- Honored with the Safety Champion award for maintaining an impeccable safety record and spearheading safety initiatives in the loom department.

- Consistently surpassed performance goals, earning recognition as a Top Performer for achieving exceptional loom utilization rates.

Certificates

- Certified Loom Operator (CLO)

- Master Weaver Certificate

- Textile Manufacturing Certification

- Warping and Sizing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Loom Operator

- Quantify your accomplishments using specific metrics and data.

- Highlight your technical skills and experience with different types of looms.

- Demonstrate your knowledge of fabric defects and inspection techniques.

- Emphasize your problem-solving abilities and proactive approach to loom maintenance.

Essential Experience Highlights for a Strong Loom Operator Resume

- Operate and maintain weaving looms to produce various types of fabrics

- Monitor loom performance, identify and resolve operational issues promptly

- Perform regular maintenance and cleaning of looms to ensure optimal functionality

- Inspect fabrics for defects, ensuring adherence to quality standards

- Collaborate with team members to optimize production processes and minimize downtime

- Maintain a clean and organized work area, adhering to safety regulations

Frequently Asked Questions (FAQ’s) For Loom Operator

What are the primary responsibilities of a Loom Operator?

Loom Operators are responsible for operating and maintaining weaving looms to produce fabrics. They monitor loom performance, identify and resolve operational issues, perform maintenance and cleaning, and inspect fabrics for defects.

What skills are required to be a successful Loom Operator?

Successful Loom Operators possess a combination of technical skills, including loom operation and maintenance, fiber knowledge, troubleshooting, and fabric inspection. They also have a strong work ethic, attention to detail, and a commitment to safety.

What are the career prospects for Loom Operators?

Loom Operators can advance their careers by becoming Loom Supervisors or managers. They can also specialize in specific areas of weaving, such as fabric design or quality control.

What is the average salary for Loom Operators?

The average salary for Loom Operators varies depending on experience, location, and industry. According to Indeed, the average salary for Loom Operators in the United States is around $40,000 per year.

What is the work environment like for Loom Operators?

Loom Operators typically work in factories or mills. The work environment can be noisy and dusty, and Operators may be required to work long hours or shifts.

What are the safety precautions that Loom Operators must follow?

Loom Operators must adhere to safety regulations to minimize the risk of accidents. These precautions include wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards.