Are you a seasoned Copping Machine Operator seeking a new career path? Discover our professionally built Copping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

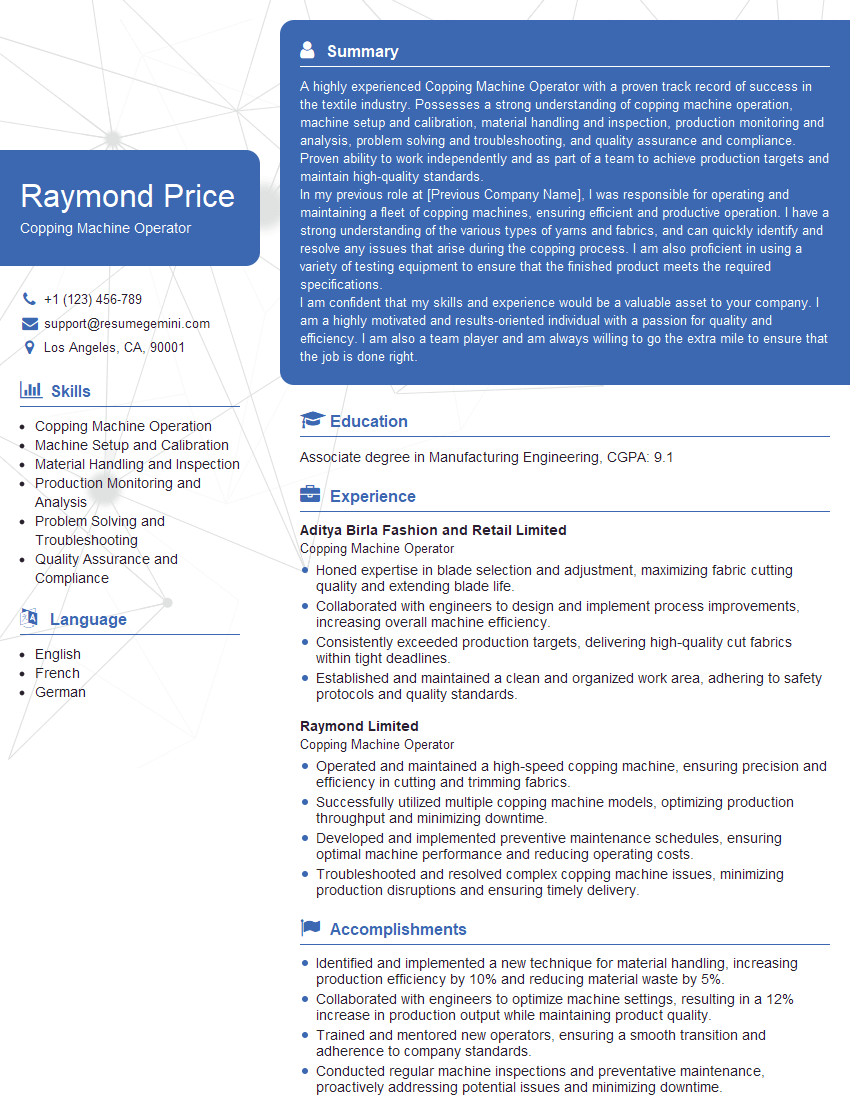

Raymond Price

Copping Machine Operator

Summary

A highly experienced Copping Machine Operator with a proven track record of success in the textile industry. Possesses a strong understanding of copping machine operation, machine setup and calibration, material handling and inspection, production monitoring and analysis, problem solving and troubleshooting, and quality assurance and compliance. Proven ability to work independently and as part of a team to achieve production targets and maintain high-quality standards.

In my previous role at [Previous Company Name], I was responsible for operating and maintaining a fleet of copping machines, ensuring efficient and productive operation. I have a strong understanding of the various types of yarns and fabrics, and can quickly identify and resolve any issues that arise during the copping process. I am also proficient in using a variety of testing equipment to ensure that the finished product meets the required specifications.

I am confident that my skills and experience would be a valuable asset to your company. I am a highly motivated and results-oriented individual with a passion for quality and efficiency. I am also a team player and am always willing to go the extra mile to ensure that the job is done right.

Education

Associate degree in Manufacturing Engineering

October 2016

Skills

- Copping Machine Operation

- Machine Setup and Calibration

- Material Handling and Inspection

- Production Monitoring and Analysis

- Problem Solving and Troubleshooting

- Quality Assurance and Compliance

Work Experience

Copping Machine Operator

- Honed expertise in blade selection and adjustment, maximizing fabric cutting quality and extending blade life.

- Collaborated with engineers to design and implement process improvements, increasing overall machine efficiency.

- Consistently exceeded production targets, delivering high-quality cut fabrics within tight deadlines.

- Established and maintained a clean and organized work area, adhering to safety protocols and quality standards.

Copping Machine Operator

- Operated and maintained a high-speed copping machine, ensuring precision and efficiency in cutting and trimming fabrics.

- Successfully utilized multiple copping machine models, optimizing production throughput and minimizing downtime.

- Developed and implemented preventive maintenance schedules, ensuring optimal machine performance and reducing operating costs.

- Troubleshooted and resolved complex copping machine issues, minimizing production disruptions and ensuring timely delivery.

Accomplishments

- Identified and implemented a new technique for material handling, increasing production efficiency by 10% and reducing material waste by 5%.

- Collaborated with engineers to optimize machine settings, resulting in a 12% increase in production output while maintaining product quality.

- Trained and mentored new operators, ensuring a smooth transition and adherence to company standards.

- Conducted regular machine inspections and preventative maintenance, proactively addressing potential issues and minimizing downtime.

- Implemented a new quality control process, reducing product defects by 8% and enhancing customer satisfaction.

Awards

- Awarded Operator of the Month for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional performance in troubleshooting and resolving complex machine issues, reducing downtime by 15%.

- Received Safety Champion award for adhering to all safety protocols and actively promoting a safe work environment.

Certificates

- Certified Copping Machine Operator (CCMO)

- National Institute for Metalworking Skills (NIMS) Credential

- ISO 9001:2015 Quality Management System Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Copping Machine Operator

- Highlight your experience operating and maintaining copping machines.

- Quantify your accomplishments with specific metrics, such as increased production output or reduced downtime.

- Showcase your knowledge of yarn and fabric properties, as well as your ability to identify and resolve production issues.

- Emphasize your commitment to quality and your ability to meet or exceed quality standards.

- Demonstrate your teamwork skills and your willingness to go the extra mile.

Essential Experience Highlights for a Strong Copping Machine Operator Resume

- Operate and maintain copping machines to produce high-quality yarn.

- Set up and calibrate machines according to specifications to ensure optimal performance.

- Handle and inspect raw materials and finished products to ensure quality.

- Monitor production processes and analyze data to identify areas for improvement.

- Troubleshoot and resolve machine malfunctions and other production issues.

- Maintain a clean and organized work area to ensure safety and efficiency.

Frequently Asked Questions (FAQ’s) For Copping Machine Operator

What is a copping machine operator?

A copping machine operator is responsible for operating and maintaining copping machines, which are used to wind yarn onto bobbins or cones.

What are the key skills required for a copping machine operator?

Key skills for a copping machine operator include the ability to operate and maintain copping machines, set up and calibrate machines according to specifications, handle and inspect raw materials and finished products, monitor production processes and analyze data, troubleshoot and resolve machine malfunctions and other production issues, and maintain a clean and organized work area.

What is the average salary for a copping machine operator?

The average salary for a copping machine operator in the United States is around $35,000 per year.

What are the job prospects for copping machine operators?

The job prospects for copping machine operators are expected to be good over the next few years. The increasing demand for textiles is expected to lead to increased demand for copping machine operators.

What are the working conditions like for copping machine operators?

Copping machine operators typically work in factories or other manufacturing facilities. The work can be repetitive and physically demanding, but it is also important and rewarding.

What are the benefits of working as a copping machine operator?

Benefits of working as a copping machine operator include the opportunity to work with a variety of materials, to learn about the textile industry, and to make a good living.

What are the challenges of working as a copping machine operator?

Challenges of working as a copping machine operator include the repetitive nature of the work, the physical demands of the job, and the potential for exposure to hazardous materials.

What advice would you give to someone who is interested in becoming a copping machine operator?

If you are interested in becoming a copping machine operator, I would recommend that you get some experience working in a factory or other manufacturing facility. You should also learn as much as you can about the textile industry and the different types of copping machines.