Are you a seasoned Polishing Section Leader and Machine Setter seeking a new career path? Discover our professionally built Polishing Section Leader and Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

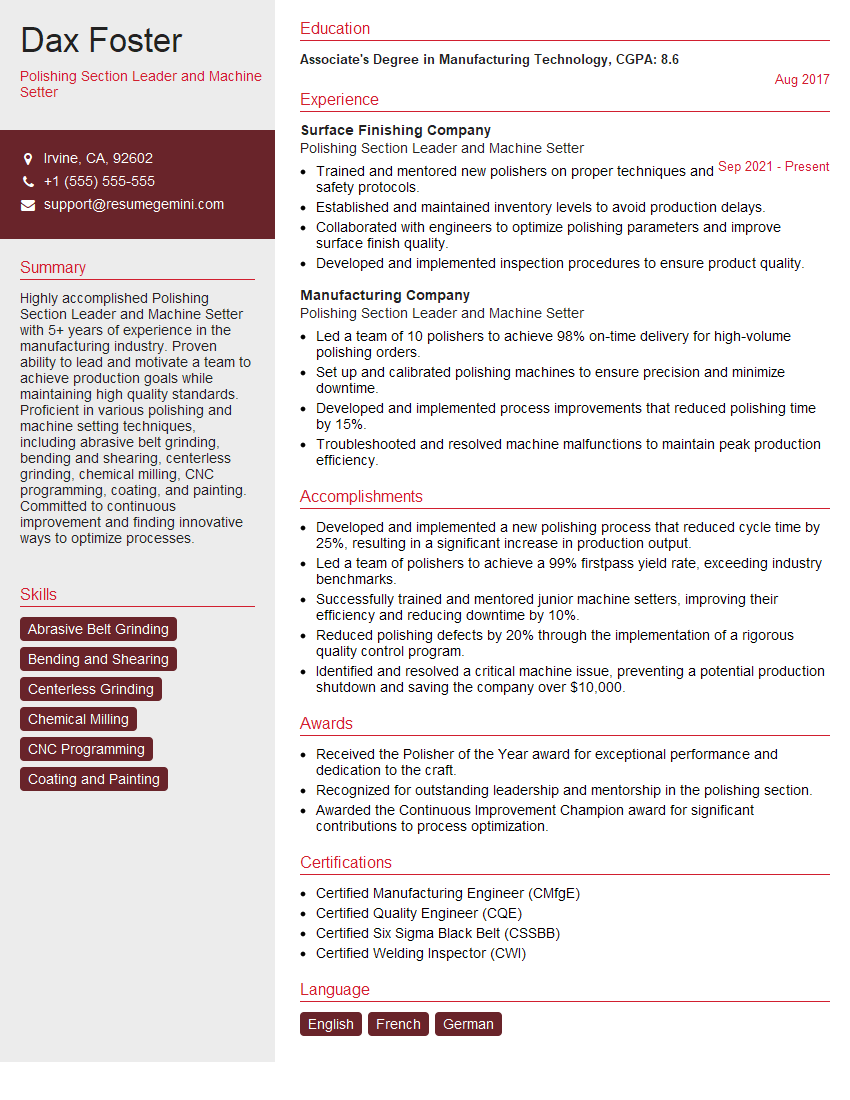

Dax Foster

Polishing Section Leader and Machine Setter

Summary

Highly accomplished Polishing Section Leader and Machine Setter with 5+ years of experience in the manufacturing industry. Proven ability to lead and motivate a team to achieve production goals while maintaining high quality standards. Proficient in various polishing and machine setting techniques, including abrasive belt grinding, bending and shearing, centerless grinding, chemical milling, CNC programming, coating, and painting. Committed to continuous improvement and finding innovative ways to optimize processes.

Education

Associate’s Degree in Manufacturing Technology

August 2017

Skills

- Abrasive Belt Grinding

- Bending and Shearing

- Centerless Grinding

- Chemical Milling

- CNC Programming

- Coating and Painting

Work Experience

Polishing Section Leader and Machine Setter

- Trained and mentored new polishers on proper techniques and safety protocols.

- Established and maintained inventory levels to avoid production delays.

- Collaborated with engineers to optimize polishing parameters and improve surface finish quality.

- Developed and implemented inspection procedures to ensure product quality.

Polishing Section Leader and Machine Setter

- Led a team of 10 polishers to achieve 98% on-time delivery for high-volume polishing orders.

- Set up and calibrated polishing machines to ensure precision and minimize downtime.

- Developed and implemented process improvements that reduced polishing time by 15%.

- Troubleshooted and resolved machine malfunctions to maintain peak production efficiency.

Accomplishments

- Developed and implemented a new polishing process that reduced cycle time by 25%, resulting in a significant increase in production output.

- Led a team of polishers to achieve a 99% firstpass yield rate, exceeding industry benchmarks.

- Successfully trained and mentored junior machine setters, improving their efficiency and reducing downtime by 10%.

- Reduced polishing defects by 20% through the implementation of a rigorous quality control program.

- Identified and resolved a critical machine issue, preventing a potential production shutdown and saving the company over $10,000.

Awards

- Received the Polisher of the Year award for exceptional performance and dedication to the craft.

- Recognized for outstanding leadership and mentorship in the polishing section.

- Awarded the Continuous Improvement Champion award for significant contributions to process optimization.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Polishing Section Leader and Machine Setter

- Highlight your experience in leading and motivating a team.

- Showcase your expertise in various polishing techniques and machine setting.

- Quantify your accomplishments and provide specific examples of process improvements you implemented.

- Demonstrate your commitment to safety and quality control.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Polishing Section Leader and Machine Setter Resume

- Supervise a team of polishing operators and ensure they follow safety protocols and maintain a clean and organized work area.

- Set up and operate polishing machines to achieve desired surface finishes on metal components.

- Inspect polished parts to ensure they meet specifications and make adjustments to machines as needed.

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain production efficiency.

- Develop and implement process improvements to enhance productivity and reduce waste.

- Maintain accurate records of production output, machine settings, and maintenance activities.

- Collaborate with other departments, such as engineering and quality control, to ensure product quality and customer satisfaction.

Frequently Asked Questions (FAQ’s) For Polishing Section Leader and Machine Setter

What are the key skills required for a Polishing Section Leader and Machine Setter?

Key skills include experience in leading and motivating a team, proficiency in various polishing techniques, expertise in machine setting, troubleshooting and problem-solving abilities, and a commitment to safety and quality control.

How can I prepare for an interview for a Polishing Section Leader and Machine Setter position?

Research the company and the specific industry, practice answering common interview questions, and be prepared to discuss your experience and skills in detail.

What is the career outlook for Polishing Section Leaders and Machine Setters?

The career outlook is positive, as there is a growing demand for skilled professionals in the manufacturing industry.

What is the average salary for a Polishing Section Leader and Machine Setter?

The average salary varies depending on experience, location, and industry, but typically ranges from $20,000 to $50,000 per year.

What are the benefits of working as a Polishing Section Leader and Machine Setter?

Benefits may include competitive salary and benefits package, opportunities for professional growth and development, and a chance to work in a dynamic and challenging environment.

What are the challenges of working as a Polishing Section Leader and Machine Setter?

Challenges may include working in a fast-paced environment, meeting production deadlines, and ensuring the quality of polished parts.

What is the most important thing to keep in mind when working as a Polishing Section Leader and Machine Setter?

The most important thing is to maintain safety and quality standards while achieving production goals.

What is the future of the Polishing Section Leader and Machine Setter profession?

The future is promising, as there is a growing demand for skilled professionals in the manufacturing industry.