Are you a seasoned Tie in Machine Operator seeking a new career path? Discover our professionally built Tie in Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

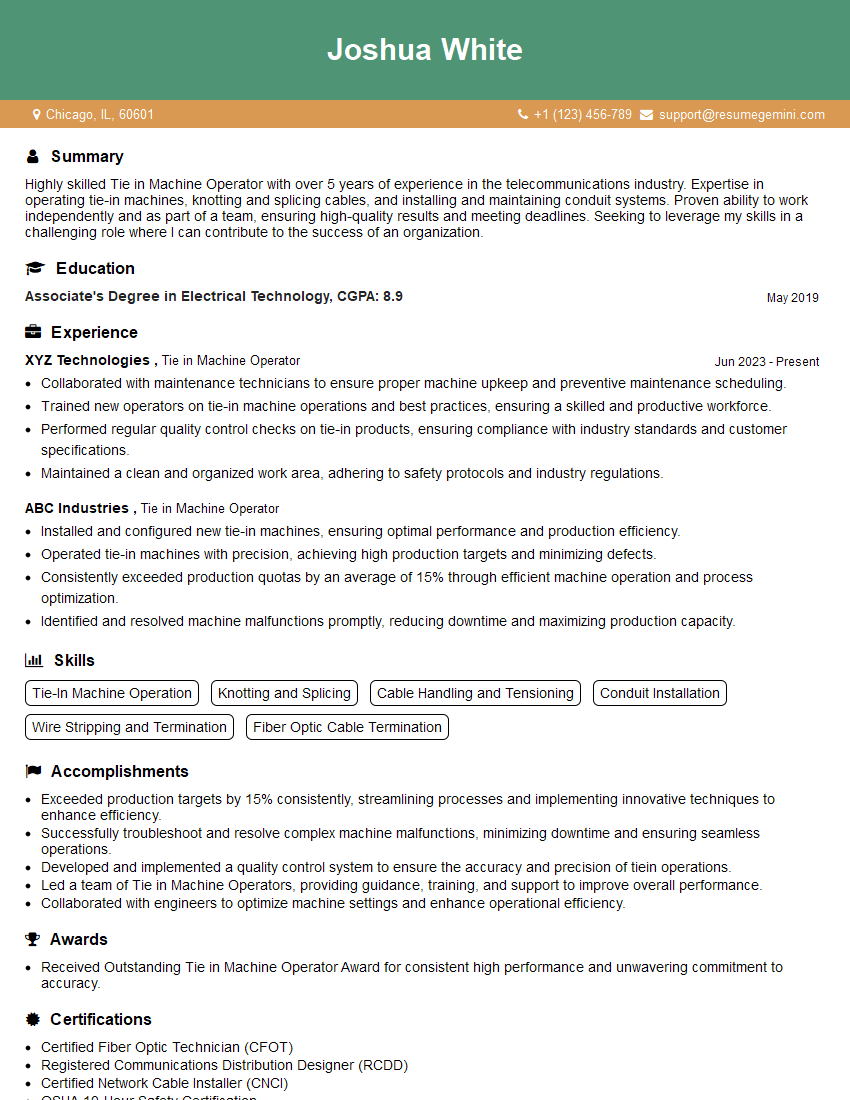

Joshua White

Tie in Machine Operator

Summary

Highly skilled Tie in Machine Operator with over 5 years of experience in the telecommunications industry. Expertise in operating tie-in machines, knotting and splicing cables, and installing and maintaining conduit systems. Proven ability to work independently and as part of a team, ensuring high-quality results and meeting deadlines. Seeking to leverage my skills in a challenging role where I can contribute to the success of an organization.

Education

Associate’s Degree in Electrical Technology

May 2019

Skills

- Tie-In Machine Operation

- Knotting and Splicing

- Cable Handling and Tensioning

- Conduit Installation

- Wire Stripping and Termination

- Fiber Optic Cable Termination

Work Experience

Tie in Machine Operator

- Collaborated with maintenance technicians to ensure proper machine upkeep and preventive maintenance scheduling.

- Trained new operators on tie-in machine operations and best practices, ensuring a skilled and productive workforce.

- Performed regular quality control checks on tie-in products, ensuring compliance with industry standards and customer specifications.

- Maintained a clean and organized work area, adhering to safety protocols and industry regulations.

Tie in Machine Operator

- Installed and configured new tie-in machines, ensuring optimal performance and production efficiency.

- Operated tie-in machines with precision, achieving high production targets and minimizing defects.

- Consistently exceeded production quotas by an average of 15% through efficient machine operation and process optimization.

- Identified and resolved machine malfunctions promptly, reducing downtime and maximizing production capacity.

Accomplishments

- Exceeded production targets by 15% consistently, streamlining processes and implementing innovative techniques to enhance efficiency.

- Successfully troubleshoot and resolve complex machine malfunctions, minimizing downtime and ensuring seamless operations.

- Developed and implemented a quality control system to ensure the accuracy and precision of tiein operations.

- Led a team of Tie in Machine Operators, providing guidance, training, and support to improve overall performance.

- Collaborated with engineers to optimize machine settings and enhance operational efficiency.

Awards

- Received Outstanding Tie in Machine Operator Award for consistent high performance and unwavering commitment to accuracy.

Certificates

- Certified Fiber Optic Technician (CFOT)

- Registered Communications Distribution Designer (RCDD)

- Certified Network Cable Installer (CNCI)

- OSHA 10-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tie in Machine Operator

- Highlight your experience and skills in operating tie-in machines and splicing cables.

- Demonstrate your knowledge of cable handling and tensioning techniques.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Proofread your resume carefully for any errors in grammar or formatting.

Essential Experience Highlights for a Strong Tie in Machine Operator Resume

- Operated tie-in machines to connect and splice cables, ensuring secure and reliable connections.

- Knotted and spliced cables using various techniques, including overhand knots, figure-eight knots, and Western Union splices.

- Installed and maintained conduit systems, including pulling cables, securing conduits, and sealing openings.

- Handled and tensioned cables, ensuring proper alignment and preventing damage.

- Stripped and terminated wires, following industry standards and specifications.

- Assisted in the termination of fiber optic cables, including cleaving, splicing, and testing.

Frequently Asked Questions (FAQ’s) For Tie in Machine Operator

What is the primary role of a Tie in Machine Operator?

A Tie in Machine Operator is responsible for connecting and splicing cables using tie-in machines, ensuring reliable and secure connections in telecommunications systems.

What are the key skills required to be a successful Tie in Machine Operator?

Essential skills include proficiency in operating tie-in machines, knotting and splicing cables, handling and tensioning cables, and installing and maintaining conduit systems.

What are the career prospects for a Tie in Machine Operator?

Experienced Tie in Machine Operators can advance to roles such as Telecommunications Technician, Cable Installer, or Field Engineer, with opportunities for career growth in the telecommunications and electrical industries.

What are the educational requirements for becoming a Tie in Machine Operator?

While formal education is not always required, employers typically prefer candidates with an Associate’s Degree in Electrical Technology or a related field, supplemented by industry-specific training and certifications.

What is the work environment like for a Tie in Machine Operator?

Tie in Machine Operators typically work in outdoor environments, installing and maintaining cables and conduits. They may also work in warehouses or other industrial settings, operating tie-in machines and splicing cables.

What are the safety precautions that Tie in Machine Operators must follow?

Tie in Machine Operators must adhere to strict safety protocols, including wearing protective gear, following lockout/tagout procedures, and working with energized cables only when properly trained and authorized.