Are you a seasoned Twisting Frame Operator seeking a new career path? Discover our professionally built Twisting Frame Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

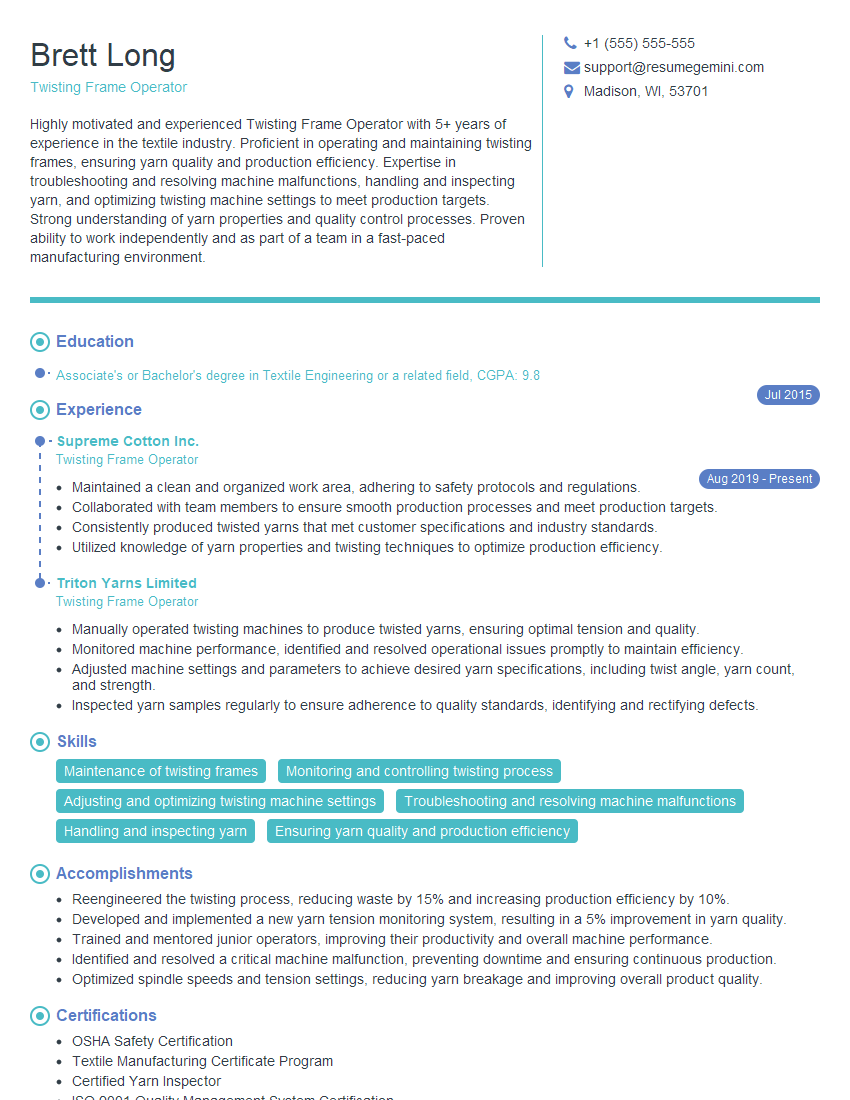

Brett Long

Twisting Frame Operator

Summary

Highly motivated and experienced Twisting Frame Operator with 5+ years of experience in the textile industry. Proficient in operating and maintaining twisting frames, ensuring yarn quality and production efficiency. Expertise in troubleshooting and resolving machine malfunctions, handling and inspecting yarn, and optimizing twisting machine settings to meet production targets. Strong understanding of yarn properties and quality control processes. Proven ability to work independently and as part of a team in a fast-paced manufacturing environment.

Education

Associate’s or Bachelor’s degree in Textile Engineering or a related field

July 2015

Skills

- Maintenance of twisting frames

- Monitoring and controlling twisting process

- Adjusting and optimizing twisting machine settings

- Troubleshooting and resolving machine malfunctions

- Handling and inspecting yarn

- Ensuring yarn quality and production efficiency

Work Experience

Twisting Frame Operator

- Maintained a clean and organized work area, adhering to safety protocols and regulations.

- Collaborated with team members to ensure smooth production processes and meet production targets.

- Consistently produced twisted yarns that met customer specifications and industry standards.

- Utilized knowledge of yarn properties and twisting techniques to optimize production efficiency.

Twisting Frame Operator

- Manually operated twisting machines to produce twisted yarns, ensuring optimal tension and quality.

- Monitored machine performance, identified and resolved operational issues promptly to maintain efficiency.

- Adjusted machine settings and parameters to achieve desired yarn specifications, including twist angle, yarn count, and strength.

- Inspected yarn samples regularly to ensure adherence to quality standards, identifying and rectifying defects.

Accomplishments

- Reengineered the twisting process, reducing waste by 15% and increasing production efficiency by 10%.

- Developed and implemented a new yarn tension monitoring system, resulting in a 5% improvement in yarn quality.

- Trained and mentored junior operators, improving their productivity and overall machine performance.

- Identified and resolved a critical machine malfunction, preventing downtime and ensuring continuous production.

- Optimized spindle speeds and tension settings, reducing yarn breakage and improving overall product quality.

Certificates

- OSHA Safety Certification

- Textile Manufacturing Certificate Program

- Certified Yarn Inspector

- ISO 9001 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Twisting Frame Operator

- Highlight your technical skills and experience in operating and maintaining twisting frames.

- Showcase your understanding of yarn properties and quality control processes.

- Quantify your accomplishments and provide specific examples of how you improved production efficiency or yarn quality.

- Emphasize your ability to work independently and as part of a team in a demanding manufacturing environment.

Essential Experience Highlights for a Strong Twisting Frame Operator Resume

- Operate and maintain twisting frames to twist yarn and produce high-quality fabric

- Monitor and control twisting process parameters such as speed, tension, and twist angle

- Adjust and optimize twisting machine settings to meet yarn specifications and production targets

- Troubleshoot and resolve machine malfunctions to minimize downtime and ensure smooth production

- Handle and inspect yarn to ensure quality and prevent defects

- Maintain accurate records of production data and machine performance

- Follow safety guidelines and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Twisting Frame Operator

What are the primary duties and responsibilities of a Twisting Frame Operator?

The primary duties include operating and maintaining twisting frames, monitoring and controlling the twisting process, adjusting and optimizing machine settings, troubleshooting and resolving malfunctions, and handling and inspecting yarn to ensure quality.

What educational qualifications are required to become a Twisting Frame Operator?

An Associate’s or Bachelor’s degree in Textile Engineering or a related field is preferred, but not always mandatory. However, experience and on-the-job training can compensate for formal education.

What are the key skills and abilities that employers look for in Twisting Frame Operators?

Employers seek individuals with technical skills in operating and maintaining twisting frames, understanding of yarn properties and quality control, and problem-solving abilities to handle machine malfunctions and ensure efficient production.

What is the career path and growth potential for a Twisting Frame Operator?

With experience and additional training, Twisting Frame Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager, or specialize in specific areas, such as yarn testing or research and development.

What are the safety precautions that Twisting Frame Operators must follow?

Twisting Frame Operators must wear appropriate safety gear, including gloves, safety glasses, and earplugs, to protect themselves from potential hazards such as moving machinery, flying yarn, and chemical exposure.

What are the employment conditions and work environment like for Twisting Frame Operators?

Twisting Frame Operators typically work in manufacturing plants, operating in shifts, and may encounter noise, dust, and exposure to chemicals. They may also be required to work overtime or on weekends to meet production demands.