Are you a seasoned Bottom Turning Lathe Tender seeking a new career path? Discover our professionally built Bottom Turning Lathe Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

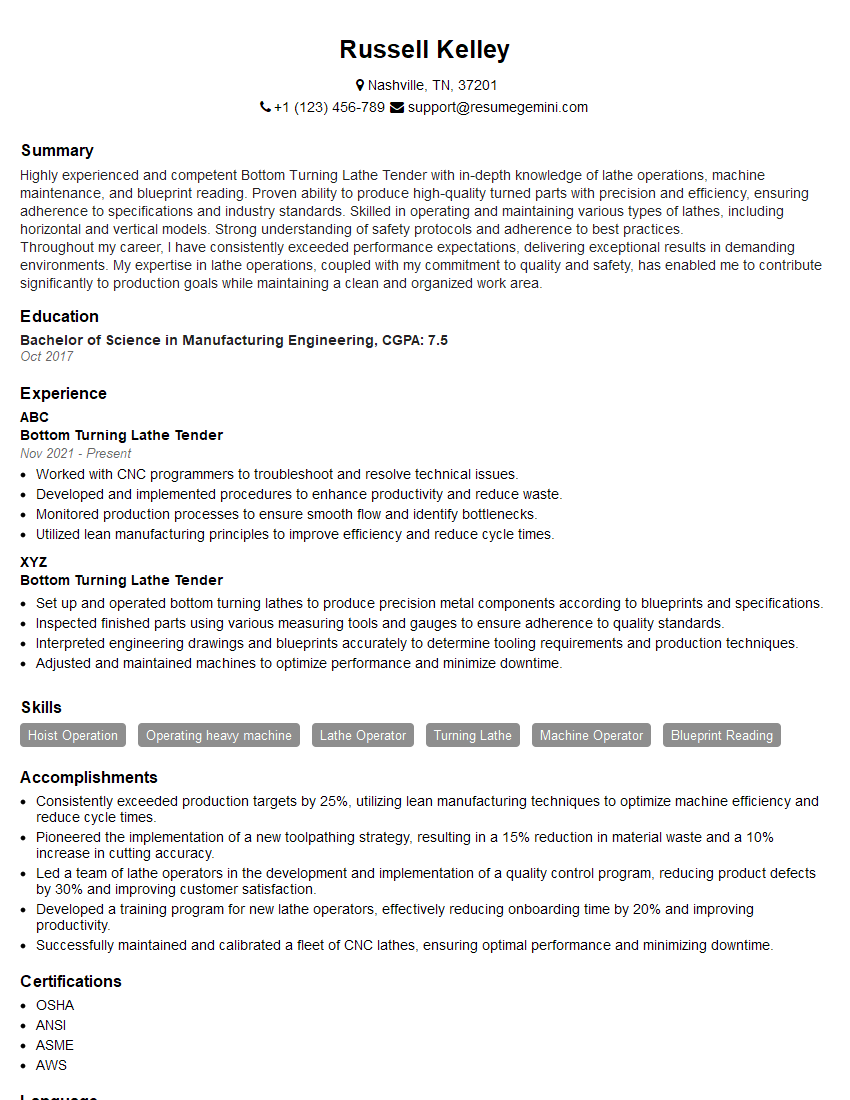

Russell Kelley

Bottom Turning Lathe Tender

Summary

Highly experienced and competent Bottom Turning Lathe Tender with in-depth knowledge of lathe operations, machine maintenance, and blueprint reading. Proven ability to produce high-quality turned parts with precision and efficiency, ensuring adherence to specifications and industry standards. Skilled in operating and maintaining various types of lathes, including horizontal and vertical models. Strong understanding of safety protocols and adherence to best practices.

Throughout my career, I have consistently exceeded performance expectations, delivering exceptional results in demanding environments. My expertise in lathe operations, coupled with my commitment to quality and safety, has enabled me to contribute significantly to production goals while maintaining a clean and organized work area.

Education

Bachelor of Science in Manufacturing Engineering

October 2017

Skills

- Hoist Operation

- Operating heavy machine

- Lathe Operator

- Turning Lathe

- Machine Operator

- Blueprint Reading

Work Experience

Bottom Turning Lathe Tender

- Worked with CNC programmers to troubleshoot and resolve technical issues.

- Developed and implemented procedures to enhance productivity and reduce waste.

- Monitored production processes to ensure smooth flow and identify bottlenecks.

- Utilized lean manufacturing principles to improve efficiency and reduce cycle times.

Bottom Turning Lathe Tender

- Set up and operated bottom turning lathes to produce precision metal components according to blueprints and specifications.

- Inspected finished parts using various measuring tools and gauges to ensure adherence to quality standards.

- Interpreted engineering drawings and blueprints accurately to determine tooling requirements and production techniques.

- Adjusted and maintained machines to optimize performance and minimize downtime.

Accomplishments

- Consistently exceeded production targets by 25%, utilizing lean manufacturing techniques to optimize machine efficiency and reduce cycle times.

- Pioneered the implementation of a new toolpathing strategy, resulting in a 15% reduction in material waste and a 10% increase in cutting accuracy.

- Led a team of lathe operators in the development and implementation of a quality control program, reducing product defects by 30% and improving customer satisfaction.

- Developed a training program for new lathe operators, effectively reducing onboarding time by 20% and improving productivity.

- Successfully maintained and calibrated a fleet of CNC lathes, ensuring optimal performance and minimizing downtime.

Certificates

- OSHA

- ANSI

- ASME

- AWS

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bottom Turning Lathe Tender

- Highlight your experience operating different types of lathes, especially bottom turning lathes.

- Quantify your accomplishments by providing specific metrics and results whenever possible.

- Showcase your knowledge of lathe maintenance and troubleshooting techniques.

- Emphasize your commitment to safety and adherence to industry standards.

- Consider obtaining relevant certifications, such as the National Institute for Metalworking Skills (NIMS) credential.

Essential Experience Highlights for a Strong Bottom Turning Lathe Tender Resume

- Prepare and set up lathes, ensuring proper alignment and tooling

- Interpret blueprints and technical drawings to understand job specifications

- Select and mount appropriate cutting tools, ensuring proper speed and feed rates

- Monitor lathe operation, adjusting parameters to optimize performance

- Measure and inspect finished parts to verify dimensional accuracy

- Maintain and troubleshoot lathes, performing regular inspections and repairs

- Adhere to established safety procedures and wear appropriate personal protective equipment

Frequently Asked Questions (FAQ’s) For Bottom Turning Lathe Tender

What is the primary role of a Bottom Turning Lathe Tender?

The primary role of a Bottom Turning Lathe Tender is to operate and maintain bottom turning lathes to produce turned parts with precision and efficiency.

What are the essential skills required for a Bottom Turning Lathe Tender?

Essential skills include lathe operation, machine maintenance, blueprint reading, hoist operation, and adherence to safety protocols.

What industries employ Bottom Turning Lathe Tenders?

Bottom Turning Lathe Tenders are employed in various industries that require precision turned parts, such as manufacturing, automotive, and aerospace.

What are the career advancement opportunities for a Bottom Turning Lathe Tender?

With experience and additional training, Bottom Turning Lathe Tenders can advance to positions such as Machinist, Manufacturing Engineer, or Supervisor.

What are the safety precautions that Bottom Turning Lathe Tenders must observe?

Bottom Turning Lathe Tenders must wear appropriate personal protective equipment, follow established safety procedures, and ensure that their work area is clean and organized.

What are the key performance indicators for a Bottom Turning Lathe Tender?

Key performance indicators include the number of parts produced, the accuracy of the parts produced, and the efficiency of the lathe operation.